4 Operating the Application

4.3 Monitoring and parameter access via operator panel

SINAMICS G120 DP at S7-1200

Entry-ID: 70155469, V1.4, 07/2018

Copyright Siemens AG 2018 All rights reserved

Start the write or read job with the

“Start Transfer” button.

Note:

After a write job the new data is

adopted as read parameters in the

white fields in the left part of the

screen. After writing you need not

trigger any additional read job for the

update.

The job status specifies how the job was

completed:

Job completed successfully

without error

The job was transferred without

errors, however, it could not be

realized in SINAMICS (e.g., a

negative time was given)

For fault diagnostics see /1/.

Terminate the write or read job by

clicking “Terminate Transfer”

The job status bits are deleted

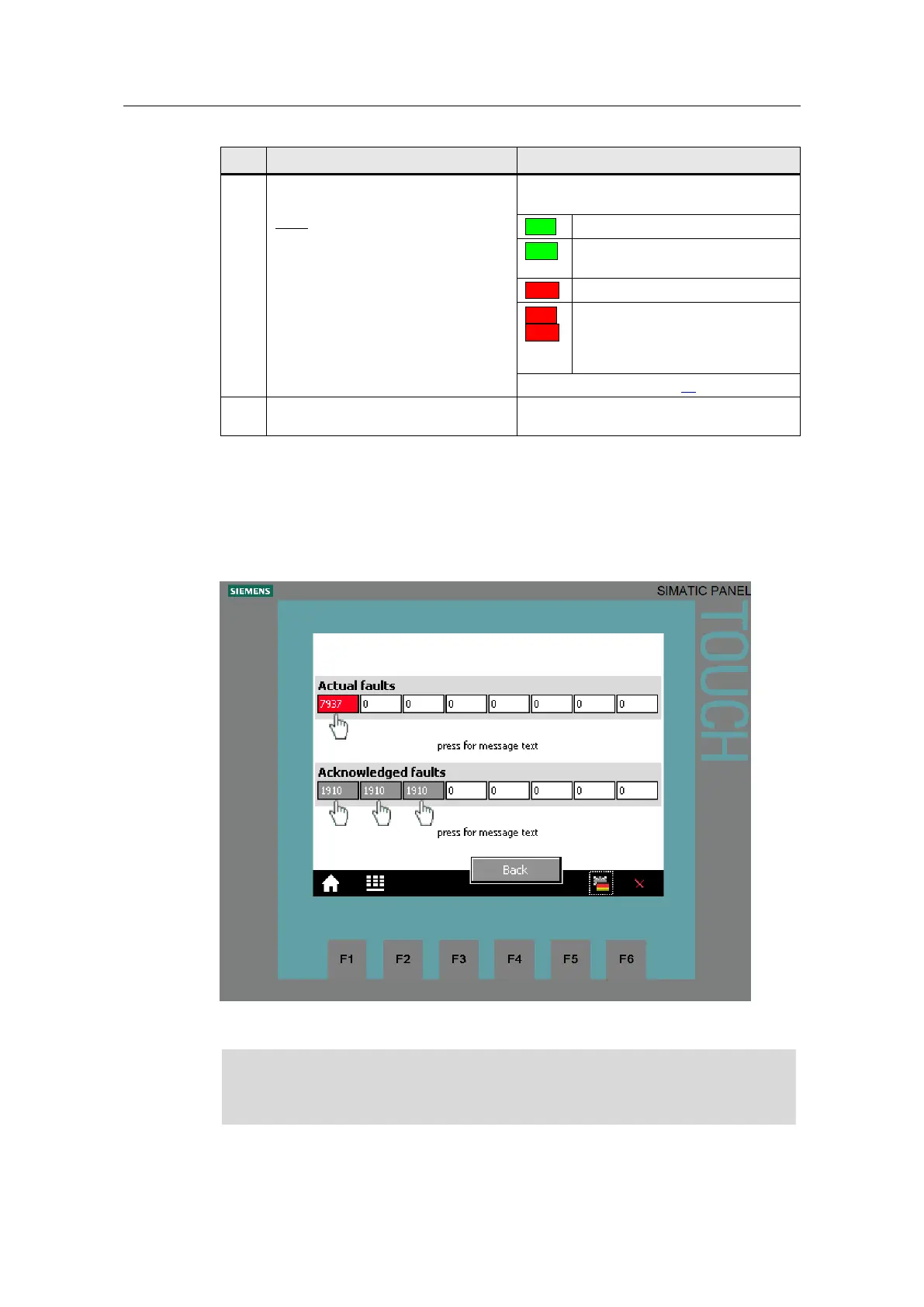

Fault buffer

The screen displays the fault codes of eight current and eight acknowledged faults,

which are saved in the SINAMICS converter.

Figure 4-7: Display of fault buffer

The fault codes in the above screen correspond to control tags V_3_Value_00

(DW18) to V_3_Value_15 (DW48) in the “answer_from_drive” data block (DB103).

The fault butters are only updated when you trigger an acyclic transmission. In

the example object, you execute the “Read parameters” function before

switching to the display of the fault buffer.

Tap or click on the message number to display the respective text.

Loading...

Loading...