● The controller can read and write data sets in conformance with PROFINET/PROFIBUS.

Special requirements for this example:

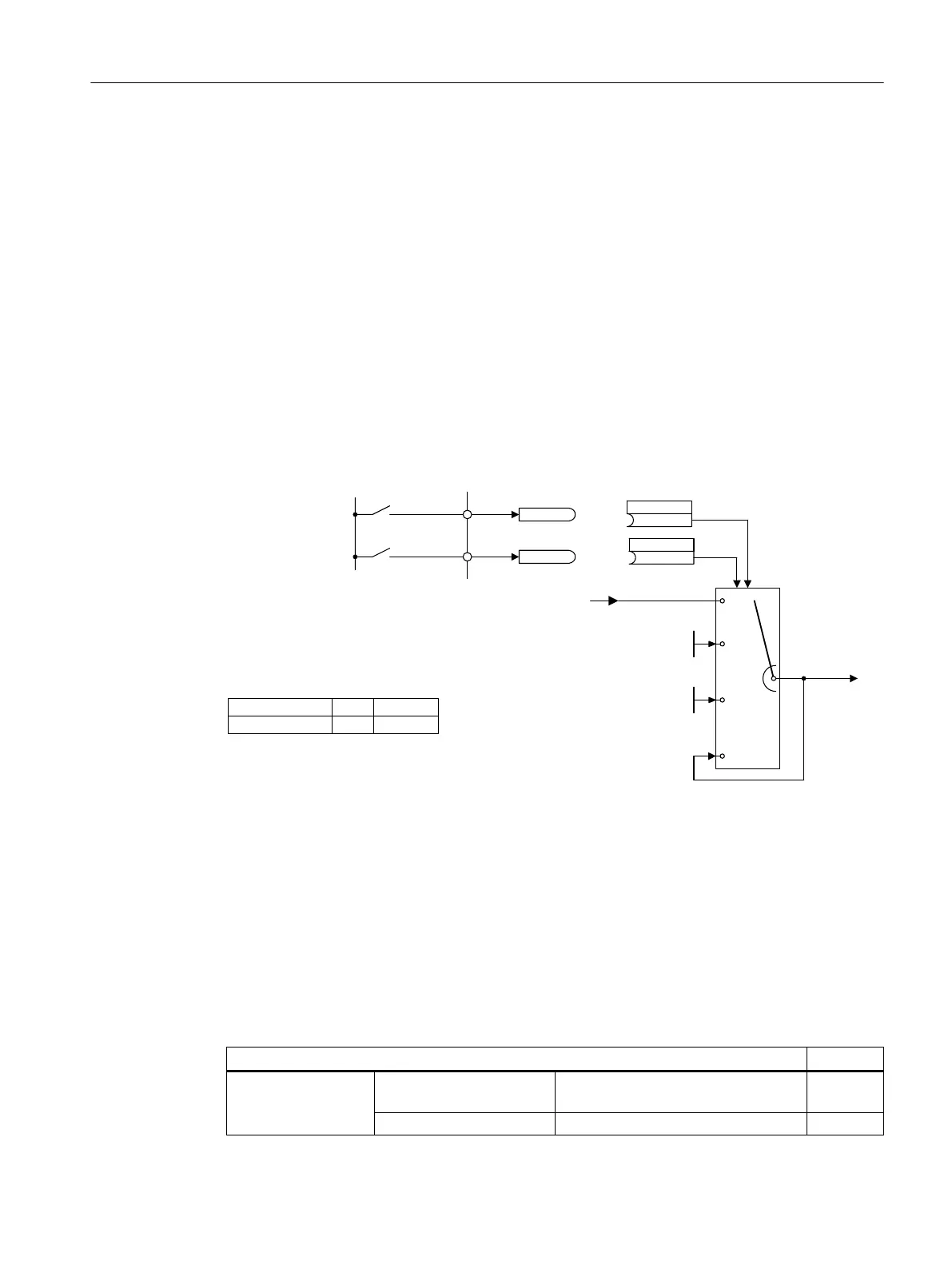

● Servo control or vector control with activated "Extended setpoint channel" function module

Task description

Jog 1 and 2 are to be set up for drive 2 (also drive object number 2) via the input terminals of

the Control Unit. A parameter request is to be used to write the corresponding parameters as

follows:

● BI: p1055 = r0722.4 Jog bit 0

● BI: p1056 = r0722.5 Jog bit 1

● p1058 = 300 rpm Jog 1 speed setpoint

● p1059 = 600 rpm Jog 2 speed setpoint

The request is to be handled using a request and response data block.

,QGH[QXPEHU

3DUDPHWHUQXPEHU

0DLQVHWSRLQW

-RJVHWSRLQW

QBVHWB

,QSXWLQ%,SDQG%,S

2EMHFW

GHYLFH

&8

:LULQJWRLWVHOI

6DYHVHWSRLQW

-RJVHWSRLQW

'+H[

'+H[

U

U

;

',

;

',

U

U

S>&@

S>&@

S

9

S

Figure A-4 Task description for multi-parameter request (example)

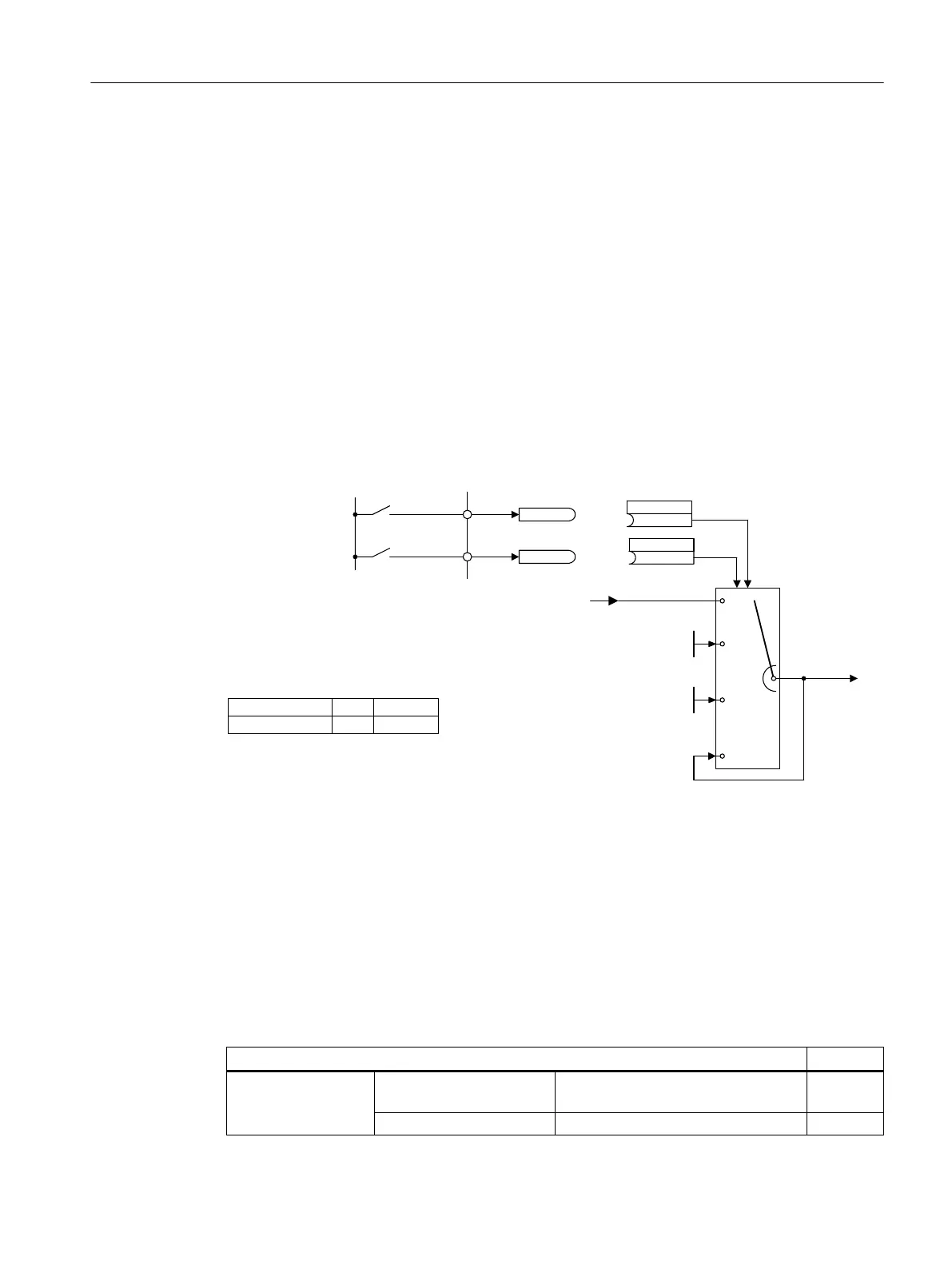

Basic procedure

1. Create a request to write the parameters.

2. Invoke the request.

3. Evaluate the response.

Create the request

Parameter request Offset

Request header Request reference = 40

hex

Request ID = 02 hex 0 + 1

Axis = 02 hex Number of parameters = 04 hex 2 + 3

Communication

A.1 Communication

Industrial Security

Configuration Manual, 08/2017, A5E36912609A 103

Loading...

Loading...