Start-Up

4.7 Commissioning

4-77

SINUMERIK 802C

6FC5 597–3AA20–0BP2 (01.02)

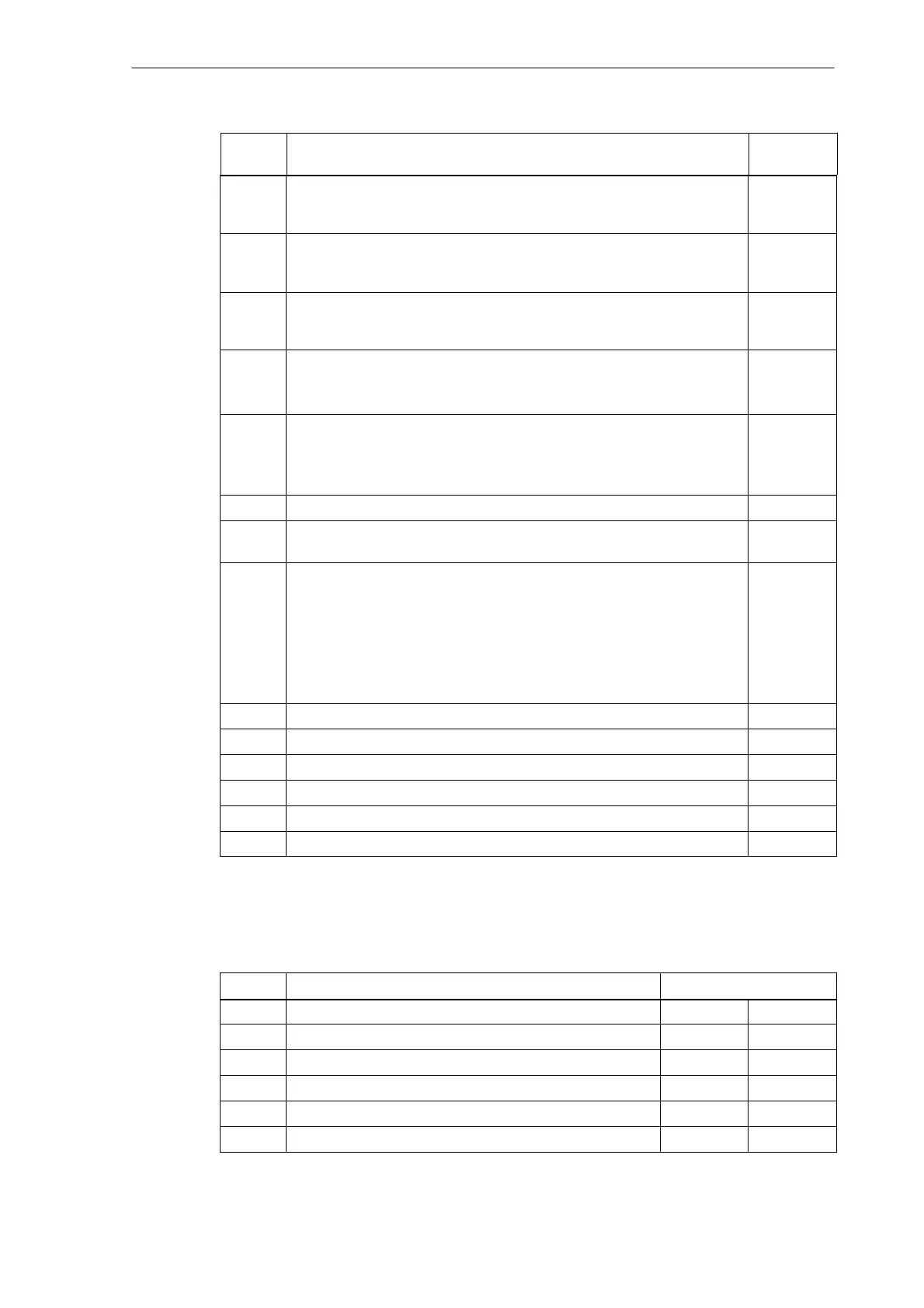

Number

Default Va-

lue

Explanation

36030

(only

SPOS)

Zero-speed tolerance

0.2

36040

(only

SPOS)

Delay zero-speed monitoring

0.4

36050

(only

SPOS)

Clamping tolerance

0.5

36060

(only

SPOS)

Maximum velocity/speed ”axis/spindle stopped” 5 (axis);

0.0138

(spindle)

36200

Threshold value for velocity monitoring (control parameter set no.): 0...5 11500

(axis);

31,94

(spindle)

36300 Encoder limit frequency 300000

36302

Encoder limit frequency at which encoder is switched on again. (Hystere-

sis)

99.9

36310

Zero mark monitoring (encoder no.):

0,1 0: Zero mark monitoring off, encoder

HW monitoring on

1-99, >100: Number of recognized zero mark errors

during monitoring

100: Zero mark monitoring off, encoder

HW monitoring off

0

36400 Contour Tol 1

36610 Duration of the deceleration ramp for error states 0.05

36620 Cutout delay servo enable 0.1

36700 Automatic drift compensation 0

36710 Drift limit value for automatic drift compensation 1

36720 Drift basic value 0

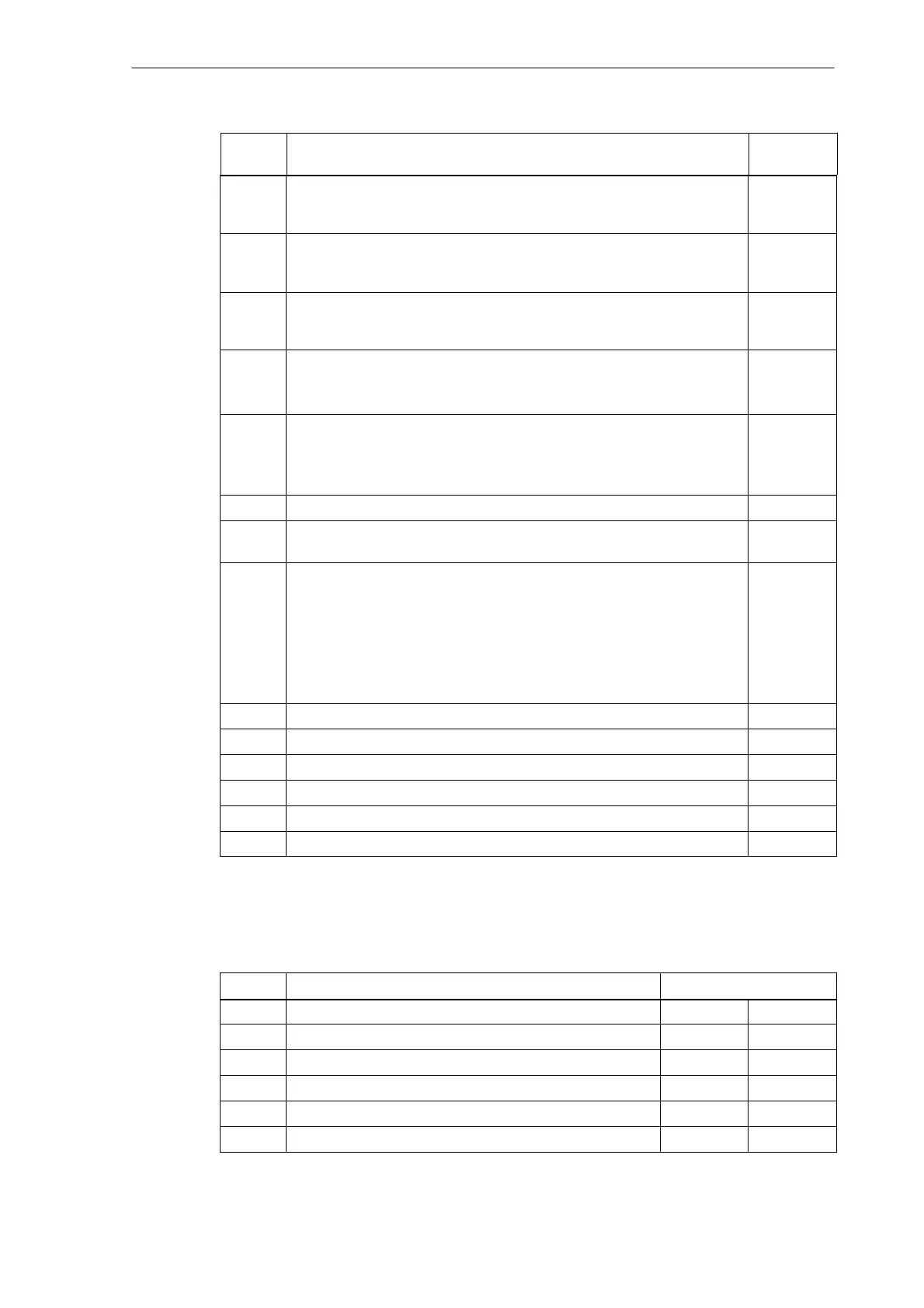

Matching encoder to axis/spindle

Machine data for encoder adjustment

Number Description Spindle

31040 Encoder mounted directly to the machine (encoder no.) 0 1

31020 Encoder markings per revolution (encoder no.) Incr. /rev. Incr. /rev.

31080 Numerator resolver gearbox (encoder no.) Motor revs Load rev.

31070 Denominator resolver gearbox (encoder no.) Enc. revs Enc. revs

31060 Numerator load gearbox (control parameter set no.): 0...5 Motor revs Motor revs

31050 Denominator load gearbox (control parameter no.): 0...5 Load revs Load revs

Loading...

Loading...