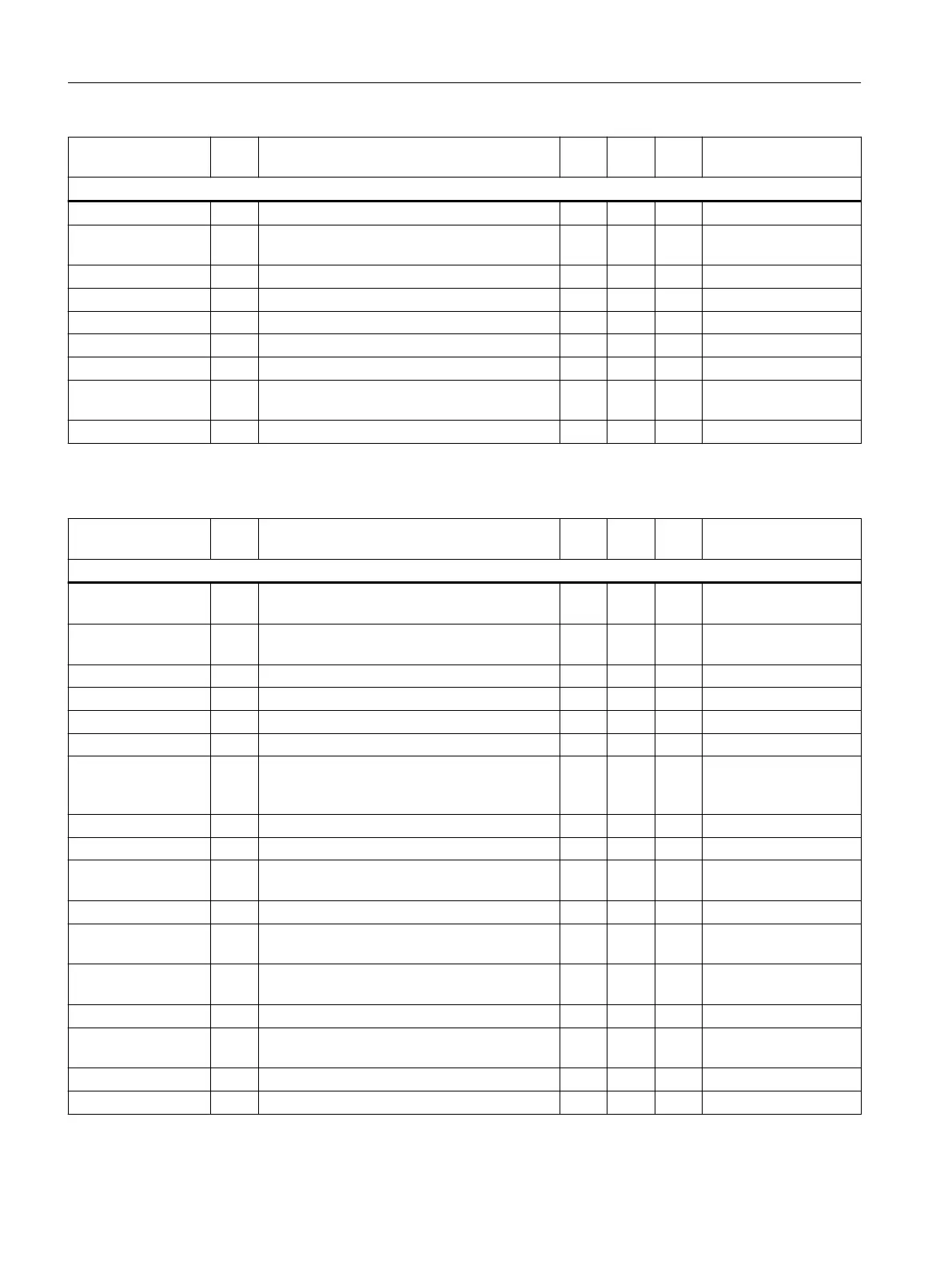

Operation Type

1)

Meaning W

2)

TP

3)

SA

4)

Description see

5)

1) 2) 3) 4) 5)

for explanations, see legend (Page 1197).

ROT G Programmable rotation s + PM-NC

ROTS G Programmable frame rotations with solid an‐

gles

s + PM-NC

ROUND F Rounding of decimal places + + PM-NC

ROUNDUP F Rounding up of an input value + + PM-NC

RP A Polar radius m/s + PM-NC

RPL A Rotation in the plane s + PM-NC

RT K Parameter for access to frame data: Rotation + PM-NC

RTLIOF G G0 without linear interpolation (single-axis in‐

terpolation)

m + PM-NC

RTLION

6)

G G0 with linear interpolation m + PM-NC

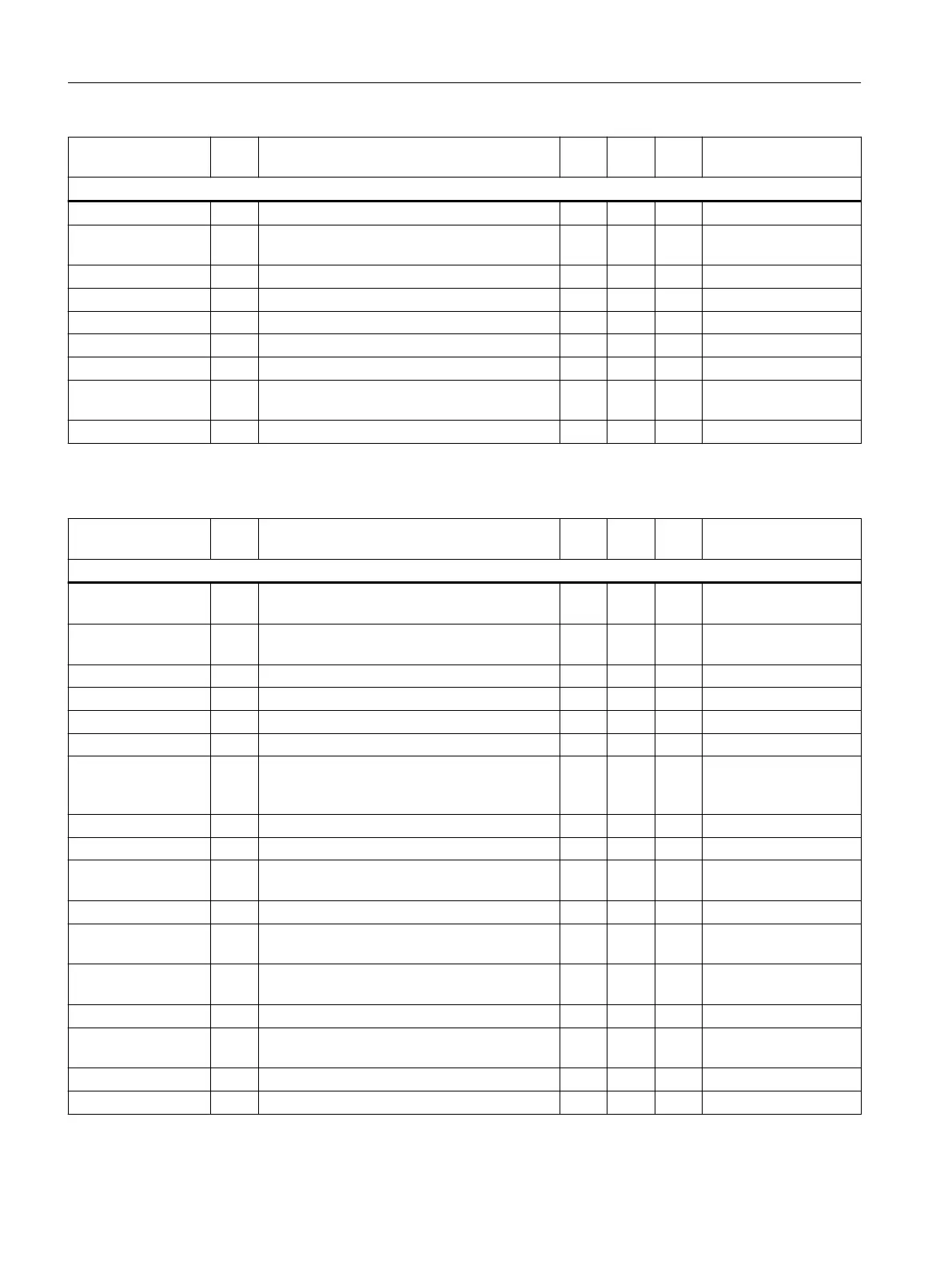

Operations S ... Z

Operation Type

1)

Meaning W

2)

TP

3)

SA

4)

Description see

5)

1) 2) 3) 4) 5)

for explanations, see legend (Page 1197).

S A Spindle speed

(with G4, G96/G961 different meaning)

m/s +/- +/- PM-NC

SAVE PA Attribute for saving information when subpro‐

grams are called

+/- PM-NC

SBLOF P Suppress single block +/- - PM-NC

SBLON P Revoke suppression of single block +/- - PM-NC

SC K Parameter for access to frame data: Scaling +/- PM-NC

SCALE G Programmable scaling s +/- PM-NC

SCC K Selective assignment of transverse axis to

G96/G961/G962. Axis identifiers may take the

form of geometry, channel or machine axes.

+/- PM-NC

SCPARA K Program servo parameter set +/- +/- PM-NC

SD A Spline degree s +/- PM-NC

SET K Keyword for initialization of all elements of an

array with listed values

+/- PM-NC

SETAL P Set alarm +/- +/- PM-NC

SETDNO F Assign the D number of a cutting edge (CE) of

a tool (T)

+/- - PM-NC

SETINT K Define which interrupt routine is to be activa‐

ted when an NC input is present

+/- PM-NC

SETM P Setting of markers in dedicated channel +/- +/- PM-NC

SETMS P Reset to the master spindle defined in ma‐

chine data

+/- - PM-NC

SETMS(n) P Set spindle n as master spindle +/- PM-NC

SETMTH P Set master toolholder number +/- - FM-TM

Tables

4.1 Operations

NC programming

1226 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...