Meaning

G74: G command call reference point approach

X1=0 Y1=0 Z1=0 … : The specified machine axis address X1, Y1, Z1 … for linear axes is

approached as the reference point.

A1=0 B1=0 C1=0 … : The specified machine axis address A1, B1, C1 … for rotary axes is

approached as the reference point.

Note

A transformation must not be programmed for an axis which is to approach the reference point

with G74.

The transformation is deactivated with command TRAFOOF.

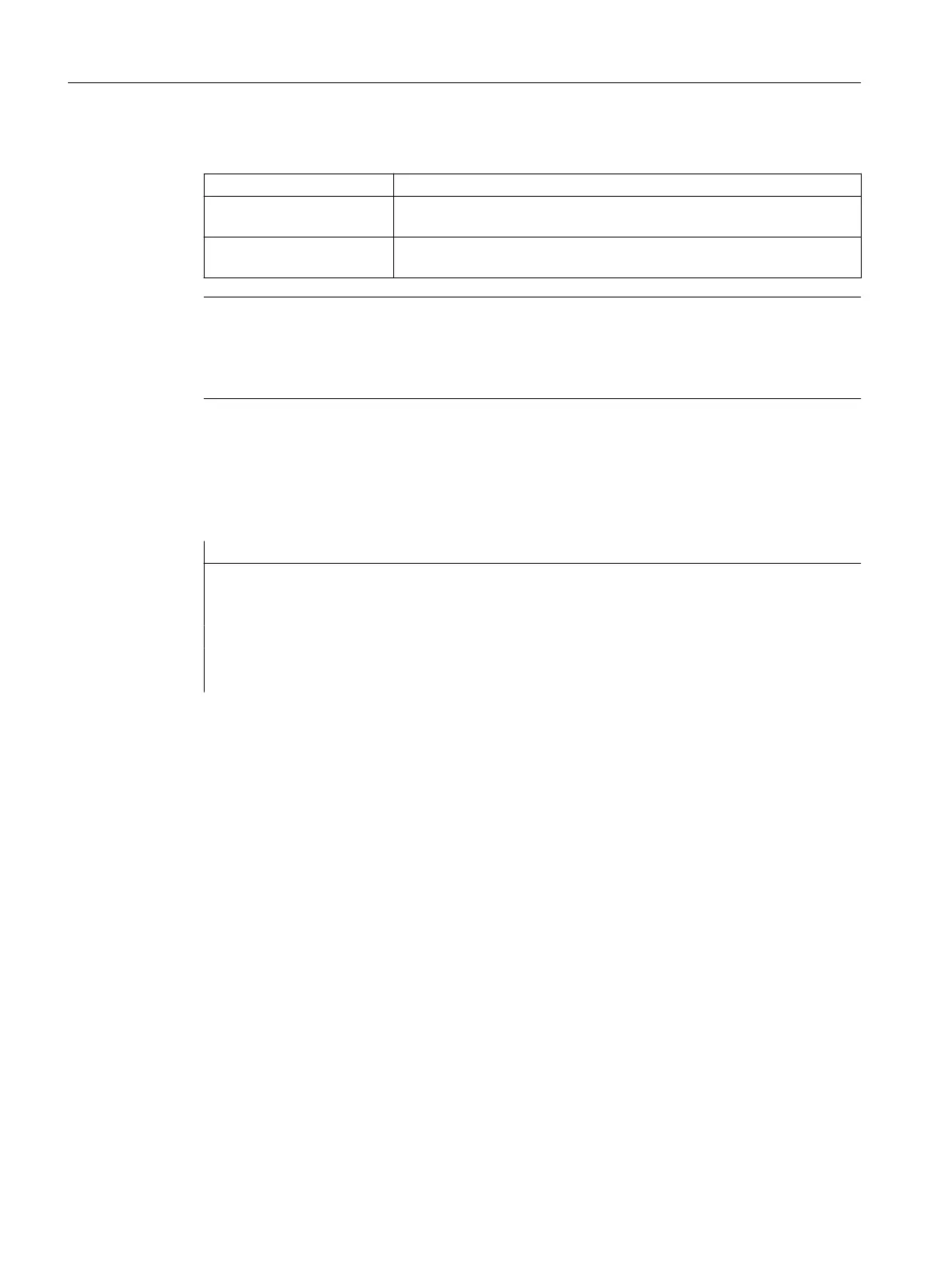

Example

When the measuring system is changed, the reference point is approached and the workpiece

zero point is set up.

Program code Comment

N10 SPOS=0 ;Spindle in position control

N20 G74 X1=0 Y1=0 Z1=0 C1=0 ;Reference point approach for linear axes and

rotary axes

N30 G54 ; Zero offset

N40 L47 ;Cutting program

N50 M30 ; End of program

2.14.5 Approaching a fixed point (G75)

The non-modal command G75 can be used to move axes individually and independently of one

another to fixed points in the machine space, e.g. to tool change points, loading points, pallet

change points, etc.

The fixed points are positions in the machine coordinate system which are stored in the

machine data (MD30600 $MA_FIX_POINT_POS[n]). A maximum of four fixed points can be

defined for each axis.

The fixed points can be approached from every NC program irrespective of the current tool or

workpiece positions. An internal preprocessing stop is executed prior to moving the axes.

Fundamentals

2.14 Supplementary commands

NC programming

358 Programming Manual, 12/2019, 6FC5398-2EP40-0BA0

Loading...

Loading...