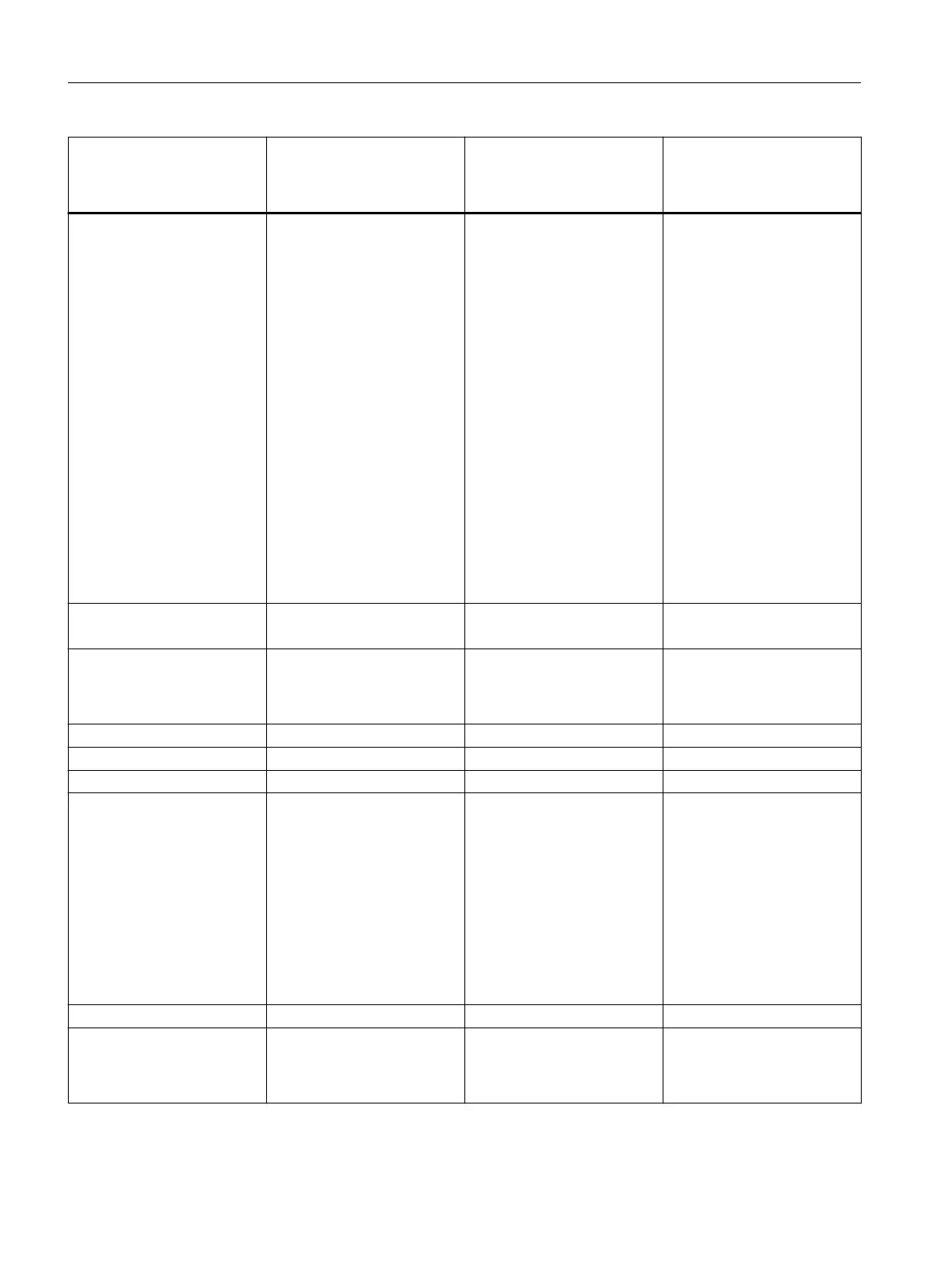

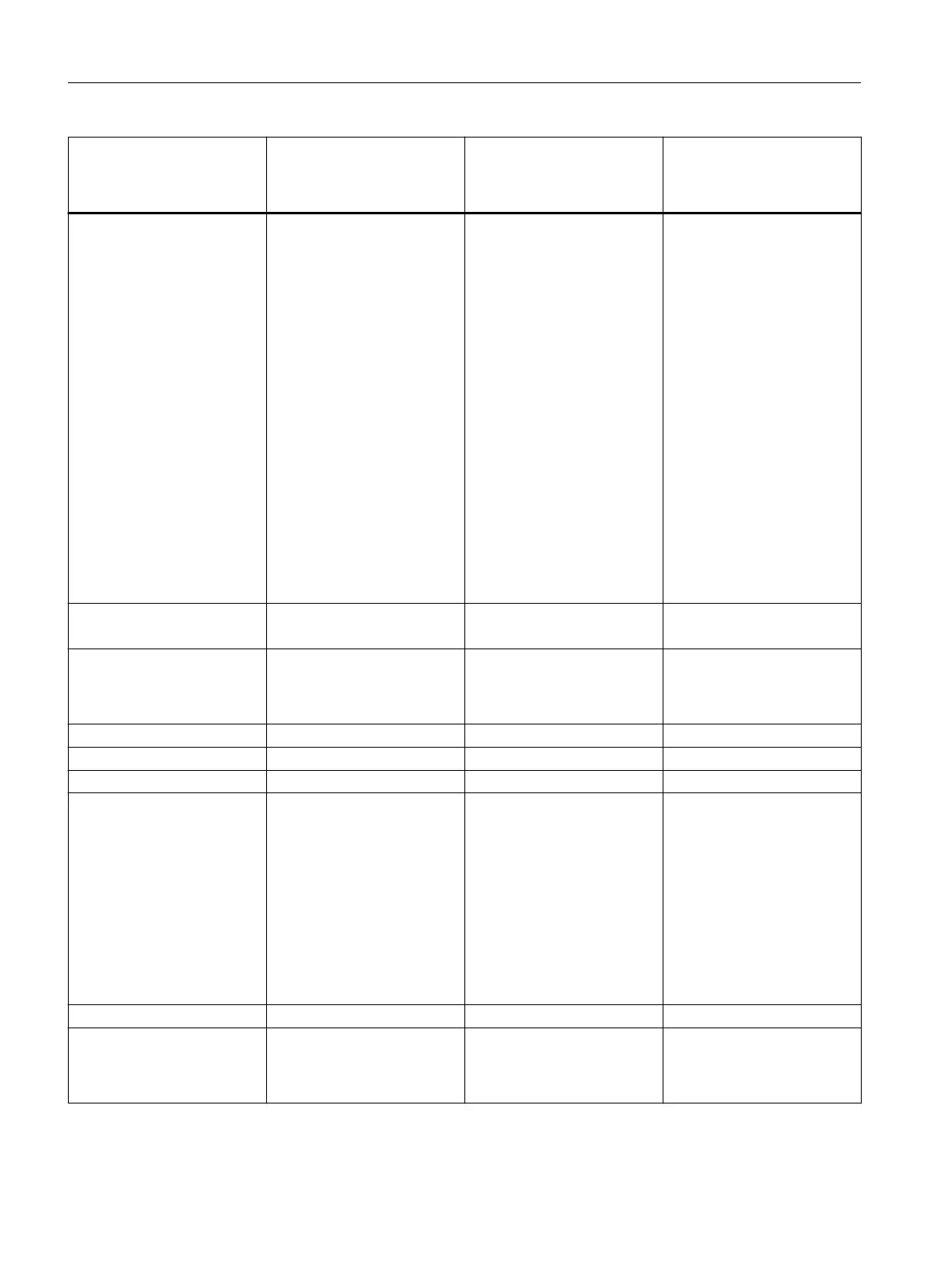

Place of installation / zone Sample gas non-ammable

below

the lower explosive limit

LEL (25% of LEL)

Flammable sample gas Sample gas is ammable

and/or is

occasionally above the LEL

(25% of LEL)

ATEX II 3G (Zone 2)

Analyzer

Ex analyzer Ex ec

(Certicate BVS 18 ATEX E 084

X,

BVS 15 ATEX E 007 X and IE‐

CEx BVS 15.0007X) (installa‐

tion in suitable

enclosure with type of protec‐

tion ec, IP54 according to

EN/IEC 60079-0 and

EN/IEC 60079-7); pollution

degree 2

Ex analyzer Ex ec

(Certicate BVS 18 ATEX E 084

X,

BVS 15 ATEX E 007 X and IE‐

CEx BVS 15.0007X) (installa‐

tion in suitable

enclosure with type of protec‐

tion ec,

IP54 according to EN/IEC

60079-0 and EN/IEC

60079-7); pollution degree 2

• OXYMAT 7, ULTRAMAT 7

and CALOMAT 7 can be

used

• Reference gas OXYMAT 7

only N2 with min. 2.2 bar

rel.

• Reference gas OXYMAT 7

must be monitored

Ex analyzer Ex ec

(Certicate BVS 18 ATEX E 084

X and

IECEx BVS 15.0007X) (instal‐

lation in suitable enclosure

with type of protection ec,

IP54 according to EN/IEC

60079-0 and EN/IEC

60079-7); pollution degree 2

• CALOMAT 7 and ULTRA‐

MAT 7 can be used

Flame arrestor Not required Not required

Recommended for OXYMAT 7

Not required

Purging Not required Required: Air exchange of at

least 5 times the enclosure

volume per hour, but at least

164 l/h must be ensured

Required: Air exchange of at

least 5 times the enclosure

volume per hour, but at least

164 l/h must be ensured

Device protection level (EPL) Gc (EPL) Gc (EPL) Gb/Gc

Non-hazardous zone

Analyzer Non-Ex analyzer Non-Ex analyzer Non-Ex analyzer

Gas path Gas path with hoses or pipes

• Pipe gas path

• Seals FFKM (option B04

for ULTRAMAT 7 and OXY‐

MAT 7)

• Regular leak test as descri‐

bed in the manual

• Evaluation regarding pos‐

sible zone displacement

must be performed by the

operator on site

• Pipe gas path

• Seals FFKM (option B04

for ULTRAMAT 7 and OXY‐

MAT 7)

• Regular leak test as descri‐

bed in the manual

• Evaluation regarding pos‐

sible zone displacement

must be performed by the

operator on site

Flame arrestor Not required Recommended Recommended

Purging Not required Required: Air exchange of at

least 5 times the enclosure

volume per hour, but at least

164 l/h must be ensured

Required: Air exchange of at

least 5 times the enclosure

volume per hour, but at least

164 l/h must be ensured

Installing/mounting

3.1Basic safety notes

SIPROCESS GA700 rack and wall mounted devices

30 Compact Operating Instructions, 06/2023, A5E35134047-AB

Loading...

Loading...