Calculation of leakage rate

A gas path is considered suciently tight for normal heated modules when the leakage rate QL

from a gas line (containment system = CS) is less than 10

-3

hPa l / s.

• Calculation of the leakage rate QL: QL = V Δp / t

The max. permissible leakage rate Q

L

always refers to the max. pressure occurring in the CS.

The leakage test is performed with air or N

2

. In metal piped analyzer modules, H

2

can also be

introduced during operation, which has half the viscosity of N

2

. Therefore, a max. permissible

leakage rate of Q

L

= 5∙10

-4

hPa l / s is applied to metal piped analyzer modules.

• Determination of the test conditions

Monitoring of the max. permissible leakage loss is carried out according to the pressure drop

method. Here, the absolute pressure p of the gas (air or N

2

) enclosed in the CS with volume V

is observed, which - if leakage is present - drops by Δp within a specied time interval t. The

amount of duck drop is a measure of the tightness of the CS.

Considering the leakage losses to be determined at the respective device type, a max.

permissible pressure drop Δp

max

results.

It is calculated as follows: Δp

max

= t Q

L

/ V

• Other

If the test volume V

new

deviates from the V assumed in the calculation of the test values, the

test value Δp

max

must be multiplied by a correction factor k, which is calculated as follows:

k = V / V

new

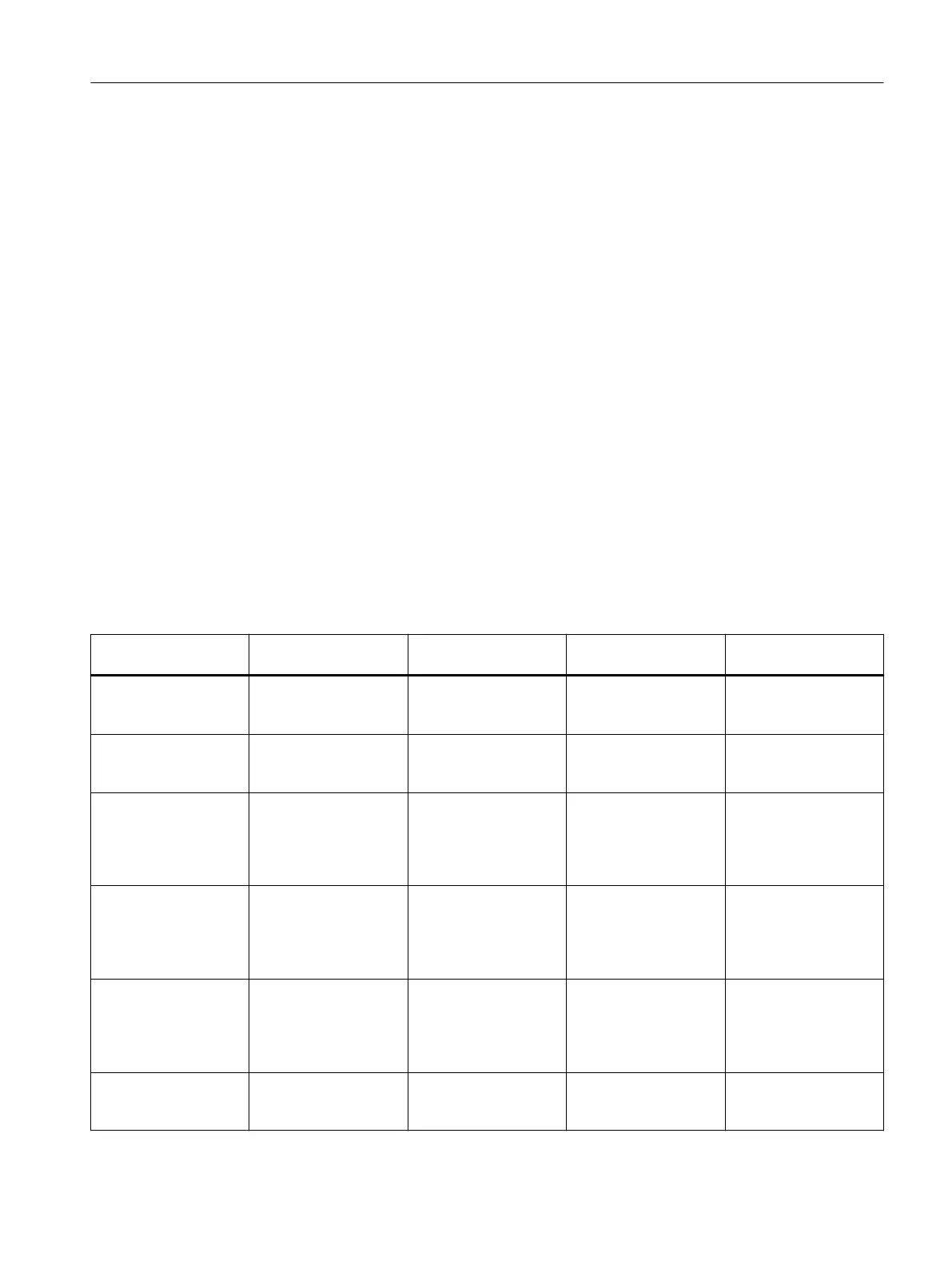

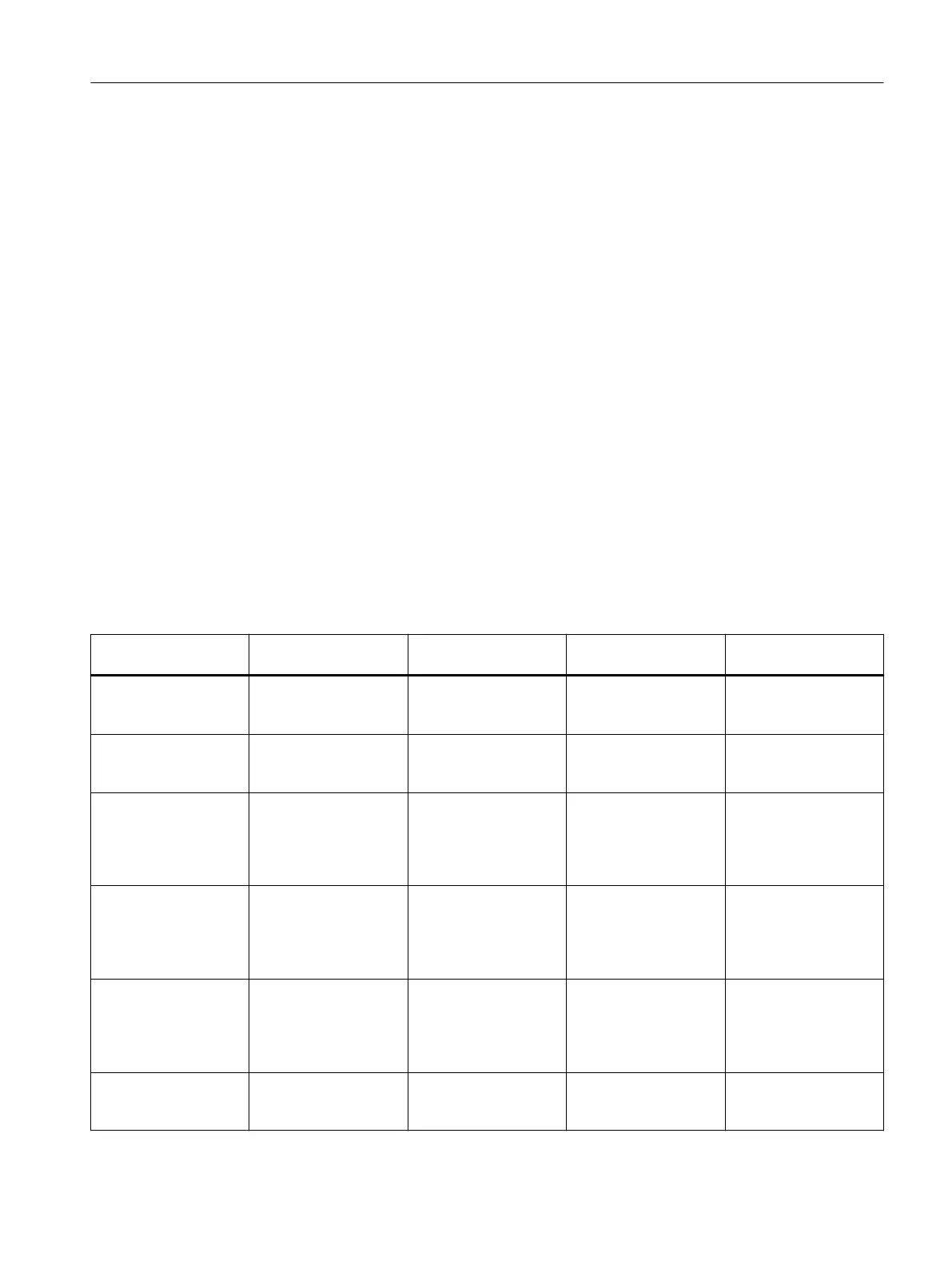

Device variant Test pressure p / hPa

rel.

Gas path volume V

0

/

ml

Max. permissible leak‐

age rate QL/(hPa ∙ l / s)

Max. perm. pressure

drop Δp

max

/ hPa

Normal heated mod‐

ule, MG path piped,

VG path tubed

100 8 10

-3

37

Normal heated mod‐

ule, MG path tubed,

VG path tubed

100 10 10

-3

30

Normal heated mod‐

ule, MG path tubed,

VG path tubed, with‐

out / with VG pressure

switch

500 7 / 8 10

-3

42 / 37

Normal heated mod‐

ule, MG path piped,

VG path tubed, with‐

out / with VG pressure

switch

2000 6 / 7 5 ∙10

-4

25 / 21

High-temperature

module, MG path pi‐

ped, RG path piped,

without / with RG

pressure switch

2000 6,5 / 7,5 5 ∙

ּ

10

-4

23 / 20

Field module, with‐

out / with RG pressure

switch

2000 15 10

-4

2

Commissioning

5.4Checking gas paths for leaks

SIPROCESS GA700 rack and wall mounted devices

Compact Operating Instructions, 06/2023, A5E35134047-AB 75

Loading...

Loading...