SINAMICS Safety Integrated (Booksize)

Commissioning the “SH” and “SBC” functions

5-168

E Siemens AG, 2004. All rights reserved

SINAMICS S120 Installation and Start-Up Manual, 12/04 Edition

5.4.3 Safety faults

Stop reaction

When Safety Integrated faults occur, the following stop reactions can be triggered:

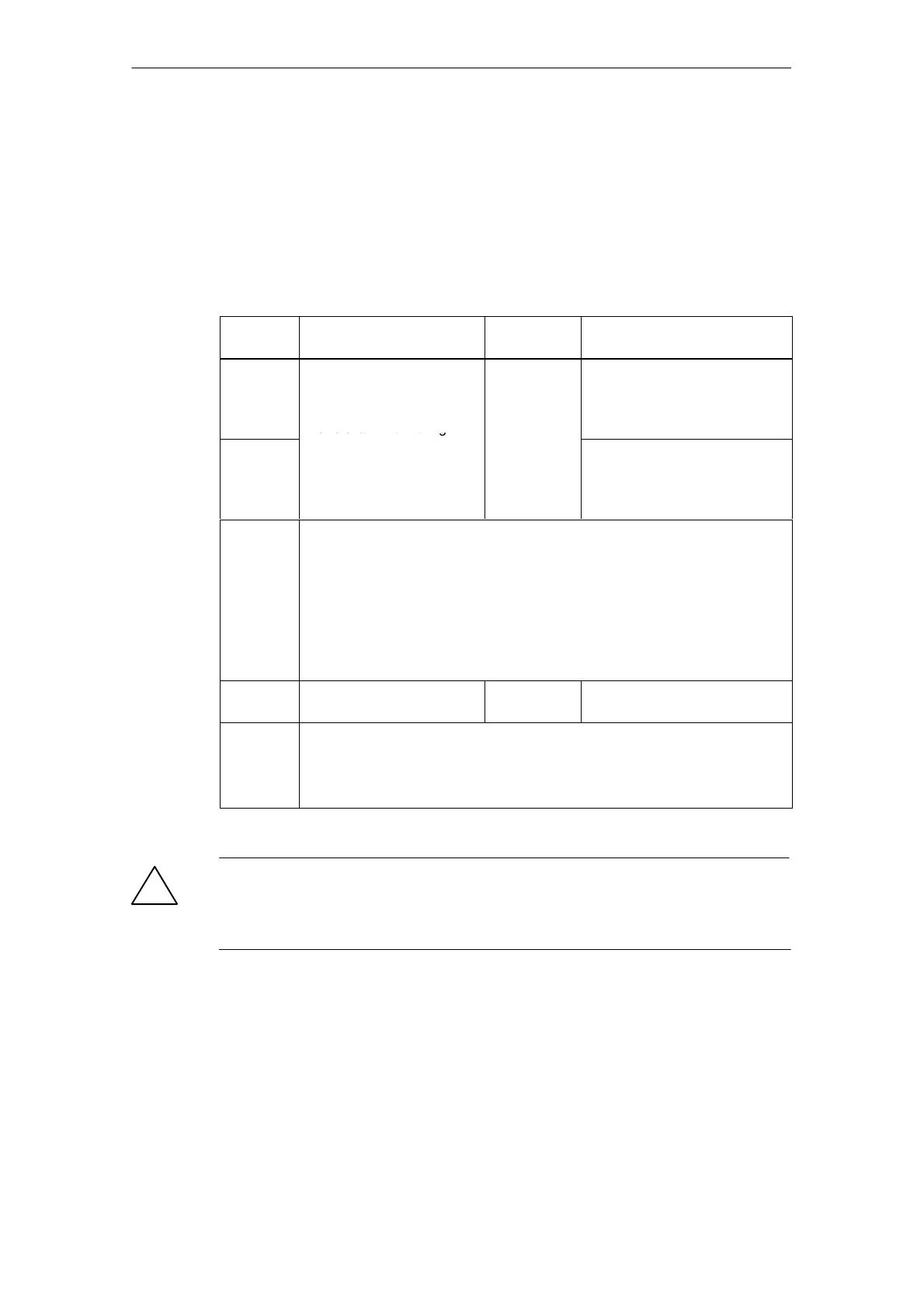

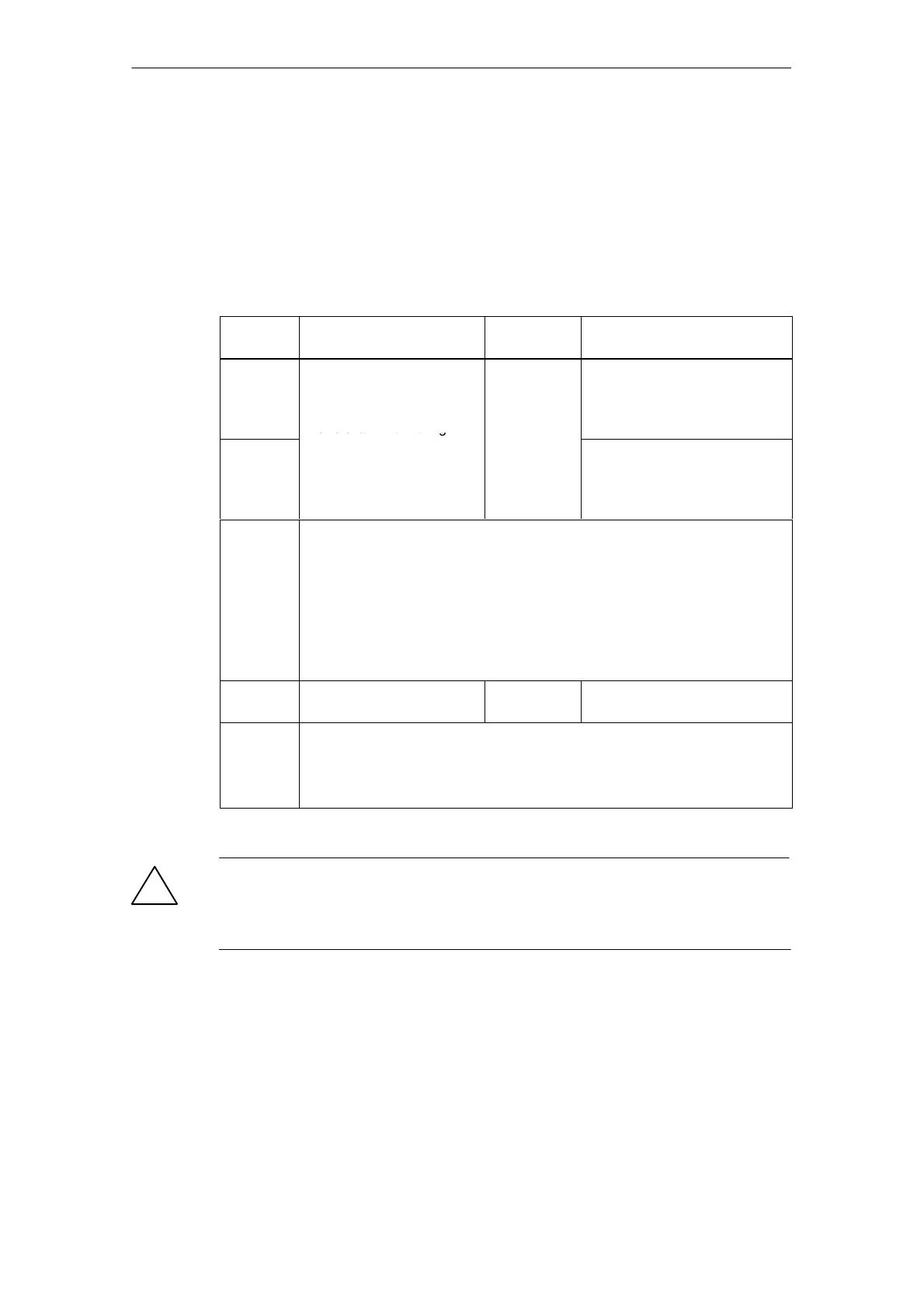

Table 5-2 Safety Integrated stop reactions

Stop

reaction

Action Effect Triggered when...

STOP A

Cannot be

acknowled

ged

Trigger safe pulse disable

via the shutdown path for

the relevant monitoring

The motor

coasts to a

standstill or

For all non-acknowledgeable

Safety faults with pulse disable.

STOP A

channel.

During operation with SBC:

apply motor holding brake.

is braked by

the holding

brake.

For all acknowledgeable Safety

faults with pulse disable.

As a follow-up reaction of

STOP F.

STOP A is identical to stop category 0 to EN 60204-1.

With STOP A, the motor is switched directly to zero torque via the “Safe

standstill (SH)” function.

A motor at standstill cannot be started again accidentally.

A moving motor coasts to standstill. This can be prevented by using external

braking mechanisms (e.g. armature short-circuiting, holding or operational

brake).

When STOP A is present, “Safe standstill (SH)” is effective.

STOP F Transition to STOP A None

If an error occurs in the

crosswise data comparison.

STOP F is permanently assigned to the crosswise data comparison (CDC). In

this way, errors are detected in the monitoring channels.

After STOP F, STOP A is triggered.

When STOP A is present, “Safe standstill (SH)” is effective.

!

Warning

With a vertical axis or pulling load, there is a risk of uncontrolled axis movements

when STOP A/F is triggered. This can be prevented by using ”Safe brake control

(SBC)” and a holding brake with sufficient retention force (non-safe).

Loading...

Loading...