SDS Series

44

Programming

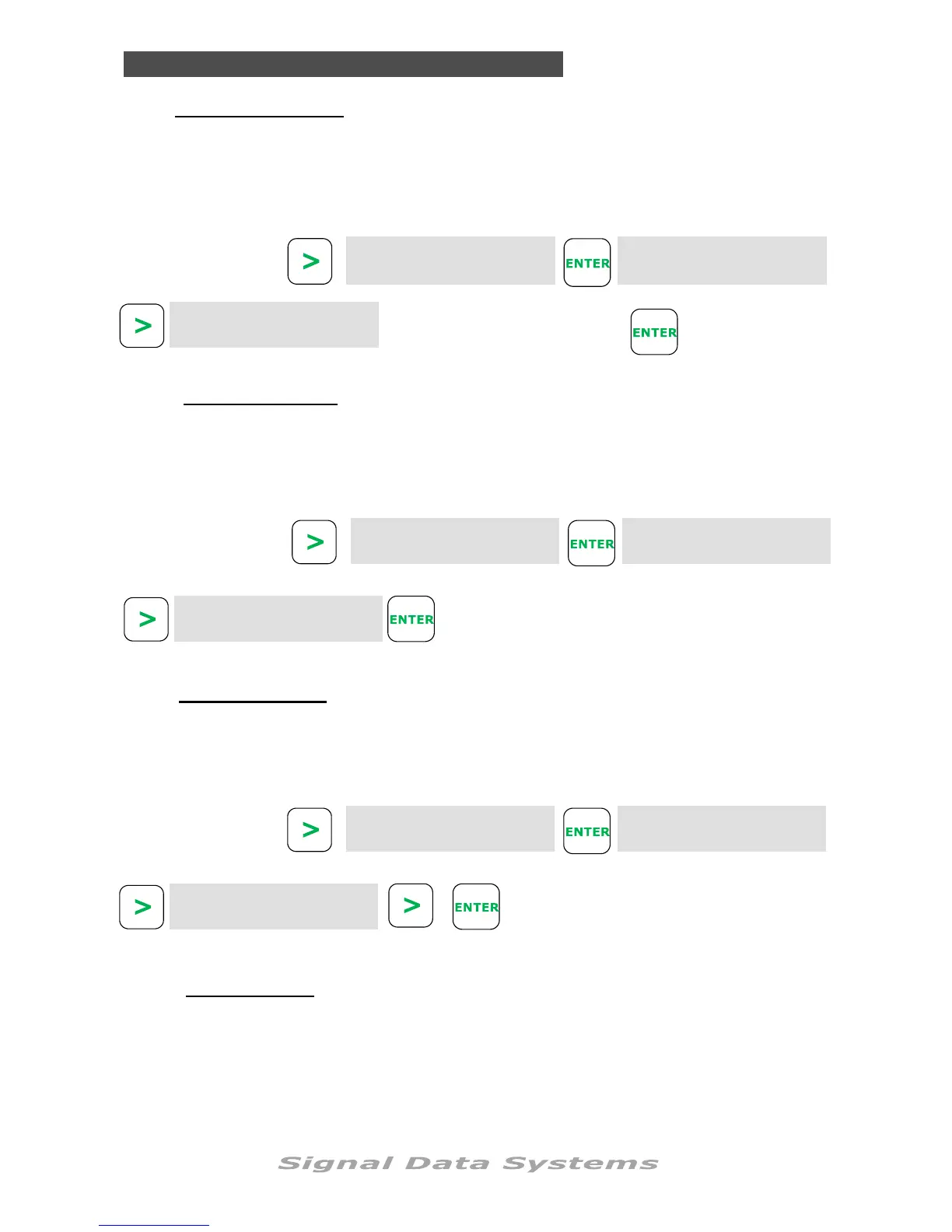

S01 02 03 04

00 00 00 00

INPUTS

< Press Enter >

Set Station Flow

< Press Enter >

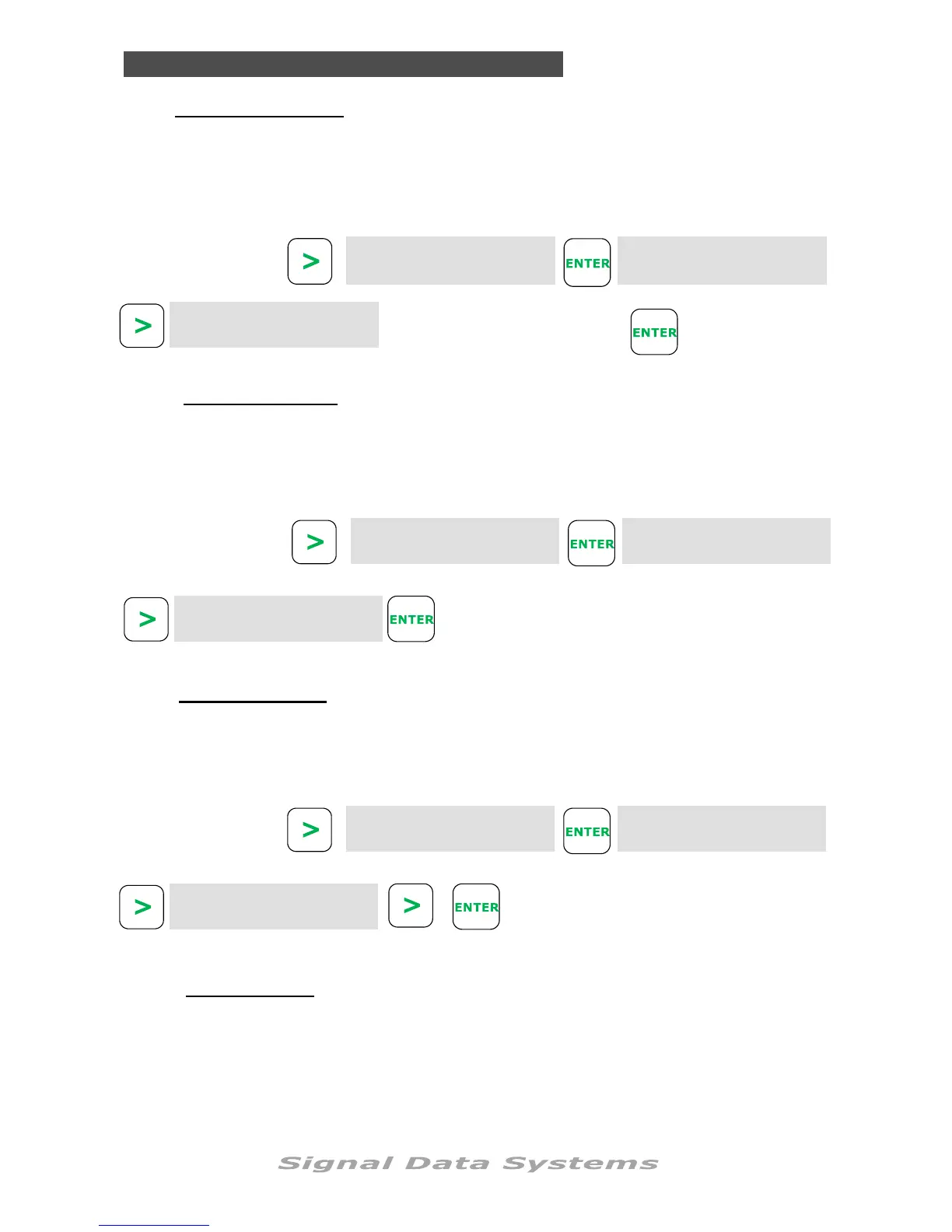

FLOW DEVIATION:

Set Deviation

20%

Once station flow has been allocated (above) a deviation percentage can be set. This is the

maximum threshold the flow can deviate above and below the normal amount. The controller

starts to monitor flow deviation after 3 minutes for the first station, with 45 seconds for sub-

sequent stations.

INPUTS

< Press Enter >

Flow Deviation

< Press Enter >

From the Time and

date display scroll

SET STATION FLOW:

This is where average station flow should be set. Do a test run of all stations, then take note

of the live flow (l/s) through each station displayed in the INFORMATION menu.

If Flow Deviation (see below) is active, then a station will skip if it falls outside the limits. If 3

stations skip in a row, the system will shutdown.

LEAK DETECTION:

Leak Detection

< Disabled >

Once enabled, the controller monitors pulses from the water meter (wired directly into the

WMD terminal). Should the controller reviece 5+ pulses whilst no programs/pumps are run-

ning, then a Leak Detection fault is logged within the controller.

INPUTS

< Press Enter >

Leak Detection

< Press Enter >

From the Time and

date display scroll

LEVEL SENSOR:

Available on the SDS-100. This feature is used with the Signal Flomag Ultrasonic Level Sensor.

Instructions on how to operate included with the sensor. Possible functions are: 1) Tank Fill 2)

Pause/Resume Irrigation 3) Shutdown program on low level 4) View live tank level display.

Also included is the ability to automatically adjust program run times to evenly distribute

available water

From the Time and

date display scroll

Key in the noted flow values.

Loading...

Loading...