SDS Series

57

Do not stretch the plunger spring as the coil’s electrical efficiency will be reduced.

Fault Finding

On initial installation, great care should taken to avoid grit contamination entering the Data-

Coil plungers. Ensure the system is properly flushed before start-up to avoid dirt/grit contam-

ination of the piping.

If a coil malfunctions, but is still reporting as online with the correct LED indication, it is al-

most certain that the coil plunger is jammed by grit. Remove from the valve, clean the plung-

er and internal coil chamber and reinstall.

It should be noted that fine grit can be difficult to see and often is only detected by feel.

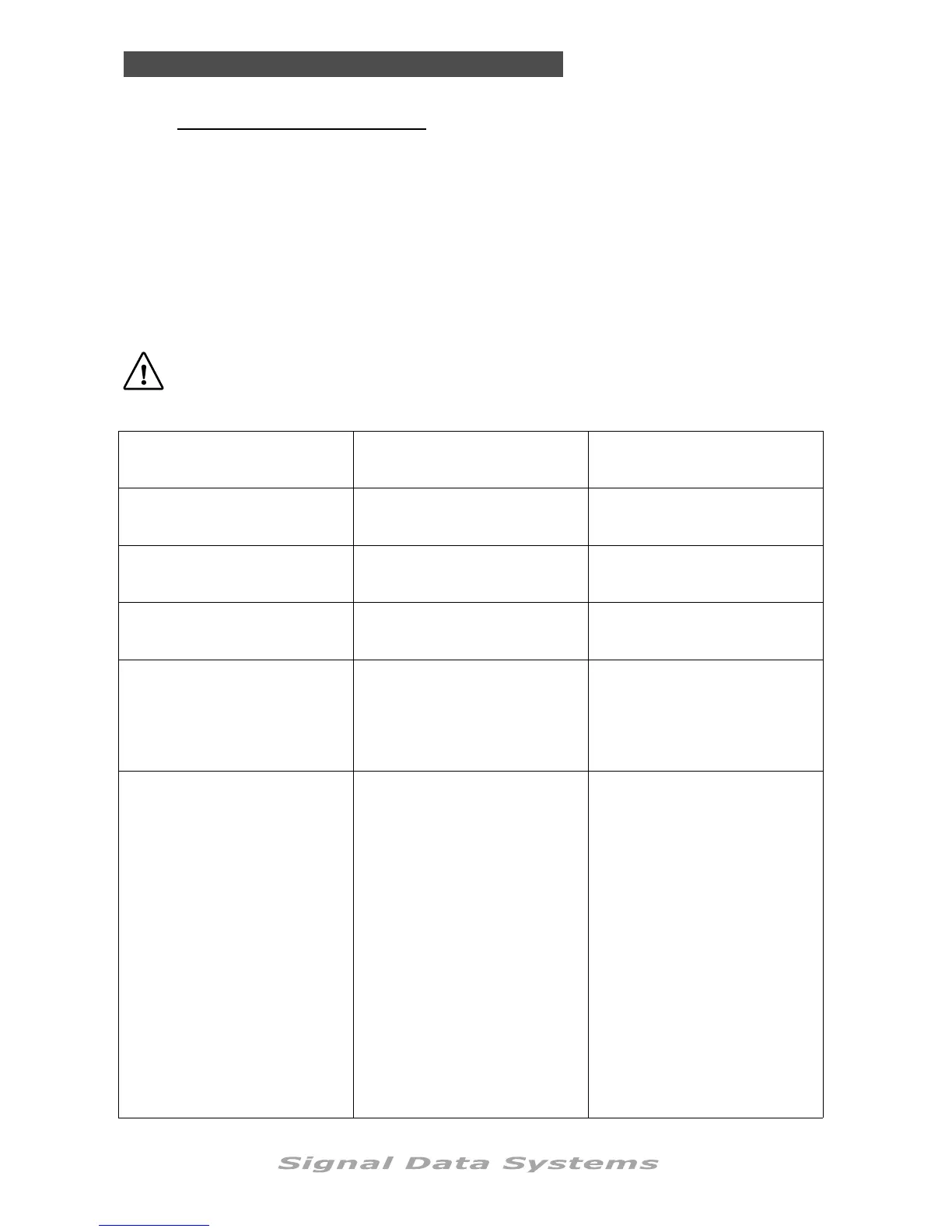

Controller Red LED is on Water meter stopped counting Check water meter output and

connections

Controller Red LED is on Pressure fault, high, skip or low Rectify hydraulic problem

Controller Red LED is on Electrical short circuit in two-wire Trace short circuit

Green LED flashes System electrical current draw is

exceeded beyond 900mA

Check for partial short circuit and

all two-wire devices for fault.

No display Faulty power supply

Faulty controller module

Test power supply input, should

be 36VDC

Observe all PCB module LEDS for

correct indication

The controller is erratic in opera-

tion or appears to have an inter-

mittent fault.

Loose electrical connections

Electrical leakage to earth

Power disruptions

Electrical, EMI interference

Faulty power supply

Faulty controller module

Make sure all electrical connec-

tions are correctly terminated.

Inspect cable connectors

Check the controller log for elec-

trical outages.

Are there any high voltage elec-

trical switchgear close by?

If variable speed pump drives are

used they must be installed

strictly to the manufactures

guidelines.

Test the controller power supply.

Observe all PCB module LEDs for

correct indication

ADDITIONAL FAULT FINDING:

Loading...

Loading...