13

Before commissioning the appliance, the whole gas installa-

tion including the meter MUST be purged and tested for gas

soundness in accordance with BS6891: 1988.

IMPORTANT: open all doors and windows, extinguish

naked lights, and DO NOT SMOKE whilst purging the

gas line.

Before commencing the commissioning procedure,

ensure that the gas service cock is turned on, the elec-

tricity supply is isolated, and that the D.H.W. and C.H.

isolation valves are in the closed position.

4.1 FILLING THE WATER SYSTEM

– Open the C.H. flow and C.H. return valves (21 fig. 2).

– Loosen the automatic air vent cap (18 fig. 2) on the flow

pipe near the heat exchanger.

– Open all radiator valves and system air vents.

Fill the system with water using one of the approved

methods described in section 2.9 to about 0.5 bar grea-

ter than the system design pressure. Close all air vents.

Do not forget the one near the pump!

– Check the system for water soundness.

– Completely drain the appliance and heating system,

thoroughly flush the system, and refill the system design

pressure.

– Open the D.H.W. inlet valve, open any hot tap, clear of

air bubbles. Close hot tap.

4.2 COMMISSIONING THE BOILER

4.2.1 V4600C mounted on “FRIENDLY” model

– Remove the screw and connect a pressure gauge to the

burner pressure test point on the gas valve (5 fig. 16/a).

– Set the Summer/Winter switch (2 fig. 24/a) to SUMMER.

Check the gas service cock is ON. Ensure that the time

clock is ON and the room thermostat is calling for heat.

Switch on the electrical supply to the boiler. Fully

depress the gas valve control button and hold in. After

approximately 15 secs. a spark will light the pilot (check

through viewing window). After a further 20 secs. relea-

se the button and the pilot should remain alight.

NOTE: on initial lighting it may take some time to

purge the air from the pilot pipe.

Check the pilot flame fully envelops 5 - 8 mm of the

thermocouple tip. If necessary adjust using regulating

screw on gas valve (6 fig. 16/a). Turn the D.H.W. tempe-

rature adjuster fully clockwise to maximum (3 fig. 17).

Fully open any D.H.W. tap and the burner will light.

–

Allow the boiler to run for at least 2 minutes and check

that the burner pressure is as stated in section 1.3. The

D.H.W. burner pressure is factory set and should not

require adjusting. If the burner pressure is low, check that

the appliance has not begun to modulate (this will occur

if the D.H.W. flow rate is low. If modulation is suspected,

open all D.H.W. taps to maximise flow and recheck bur-

ner pressure). If it is necessary to adjust the D.H.W. bur-

ner pressure the method is described in section 8.6.

– Reduce the D.H.W. draw off rate to the minimum neces-

sary to maintain the burner alight by carefully adjusting

the D.H.W. inlet valve and check that the burner pressu-

re decreases in response to D.H.W. temperature rise.

Fully open the inlet valve.

– Close the D.H.W. tap and ensure that the burner is

extinguished and the pump stops.

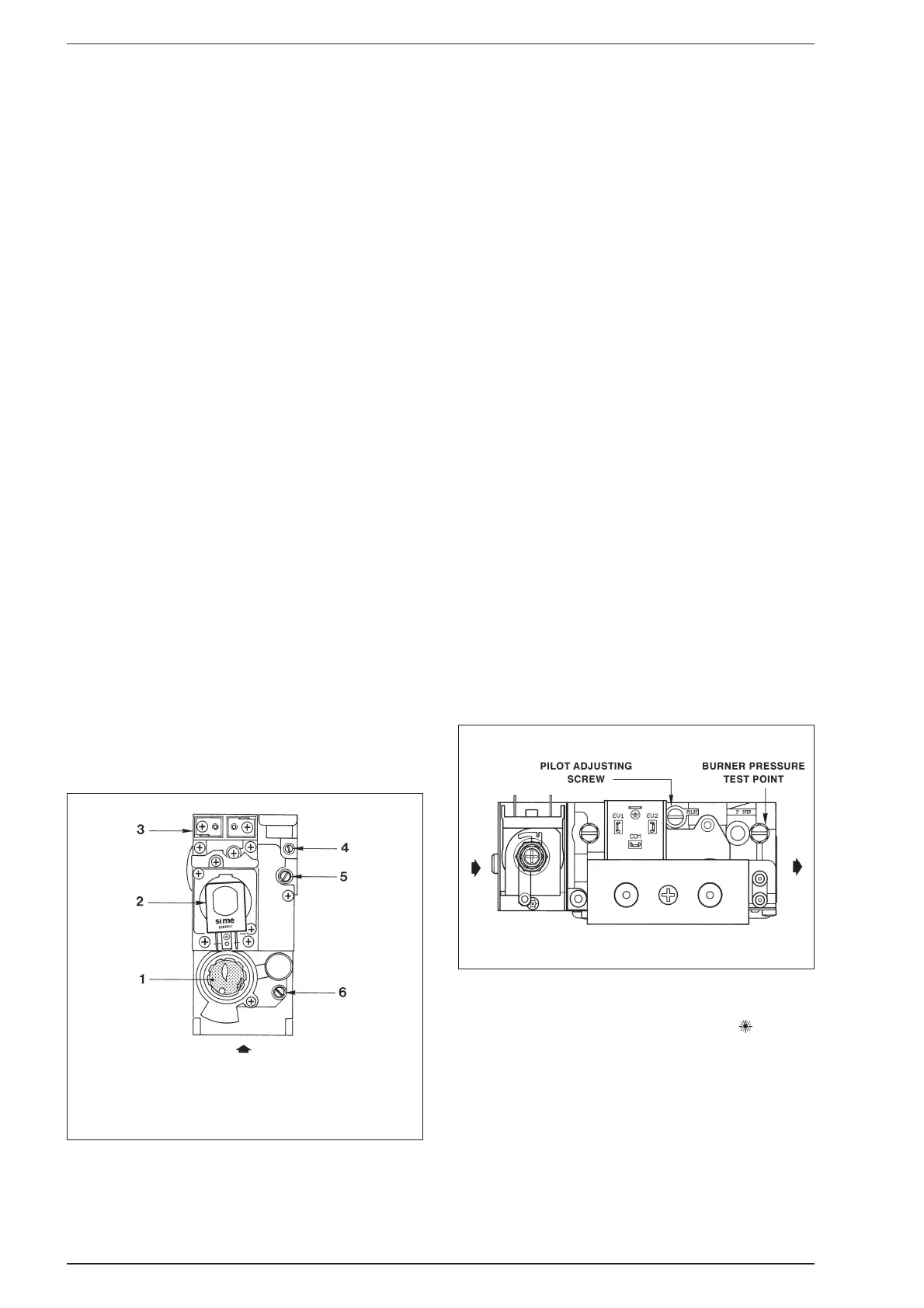

4.2.2 SIT 837 TANDEM mounted on “FRIENDLY E” model

– Remove the screw and connect a pressure gauge to the

burner pressure test point on the gas valve (fig. 16/b).

–

Ensure that the Summer/Winter switch on the facia panel

(2 fig. 24/b) is set to the SUMMER position “ ” (D.H.W.

Only), turn the D.H.W. thermostat (3 fig. 17) to maximum

(fully clockwise), and turn on the electrical supply. Fully

open any D.H.W. tap and the burner will light.

–

Allow the boiler to run for at least 2 minutes and check

that the burner pressure is as stated in section 1.3.

The D.H.W. burner pressure is factory set and should not

require adjusting. If the burner pressure is low, check that

the appliance has not begun to modulate (this will occur

if the D.H.W. flow rate is low. If modulation is suspected,

open all D.H.W. taps to maximise flow and recheck bur-

ner pressure). If it is necessary to adjust the D.H.W. bur-

ner pressure the method is described in section 8.6.

4 COMMISSIONING AND TESTING

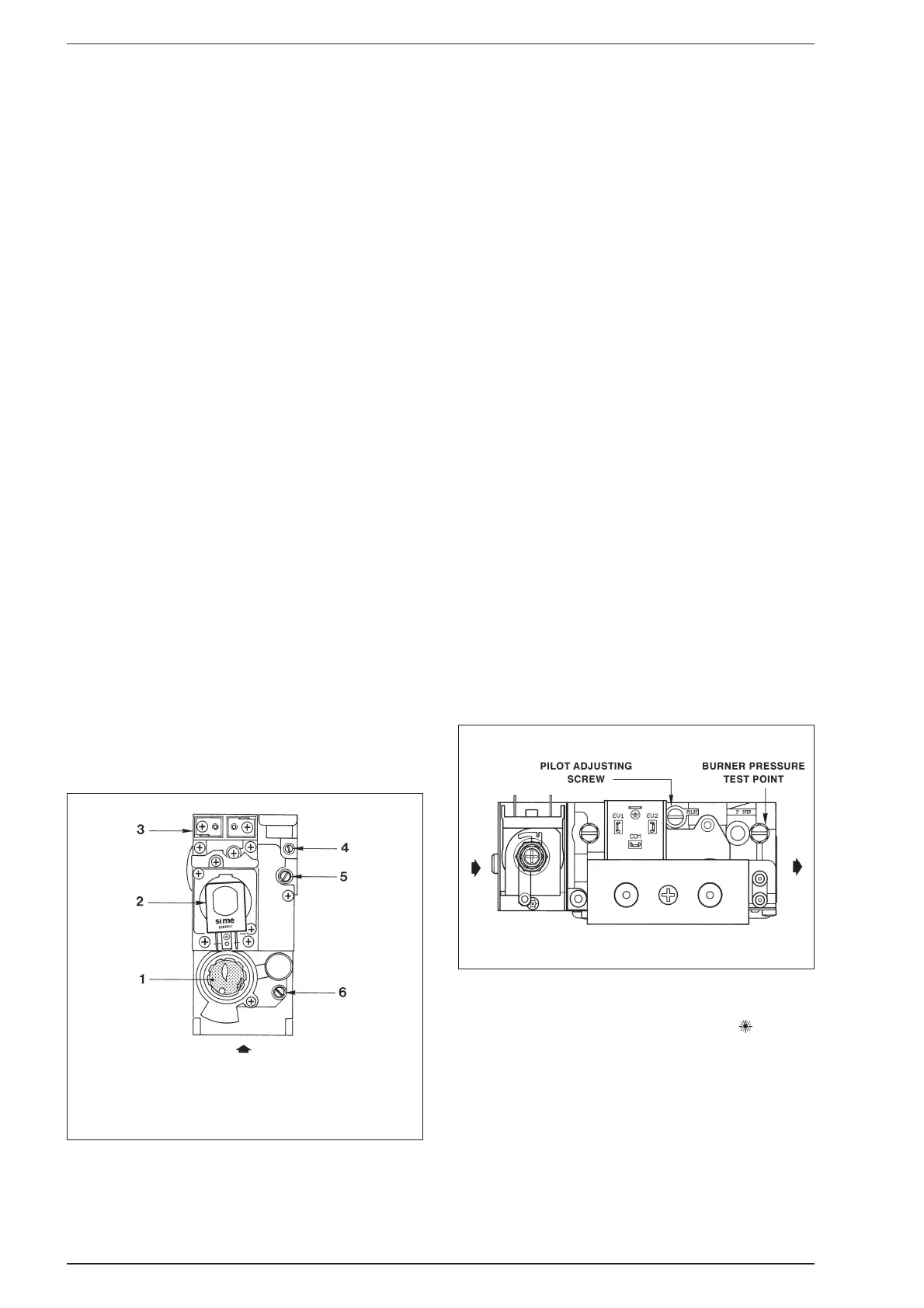

KEY

1 Control button

2 Modulating coil

3 Electric operator

Fig. 16/a

Fig. 16/b

4 Inlet pressure test point

5 Burner pressure test point

6 Pilot adjusting screw

Loading...

Loading...