– isolate the mains electricity supply and reconnect

(push on) the two 24 V modulation leads (polarity is

immaterial). Restore the mains supply. The appliance

will light on maximum input. Check that the burner

pressure corresponds to the values given in the pre-

vious points;

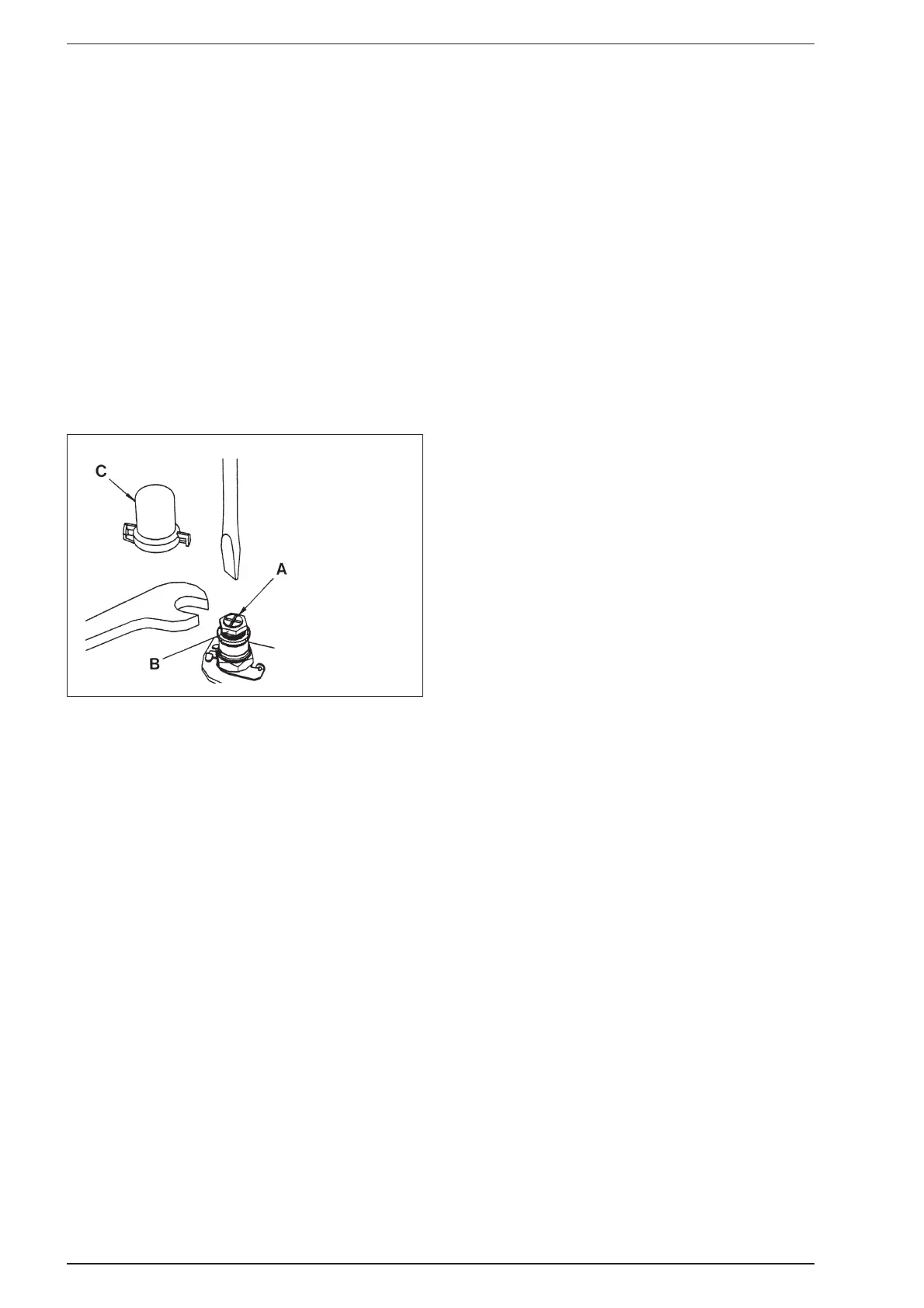

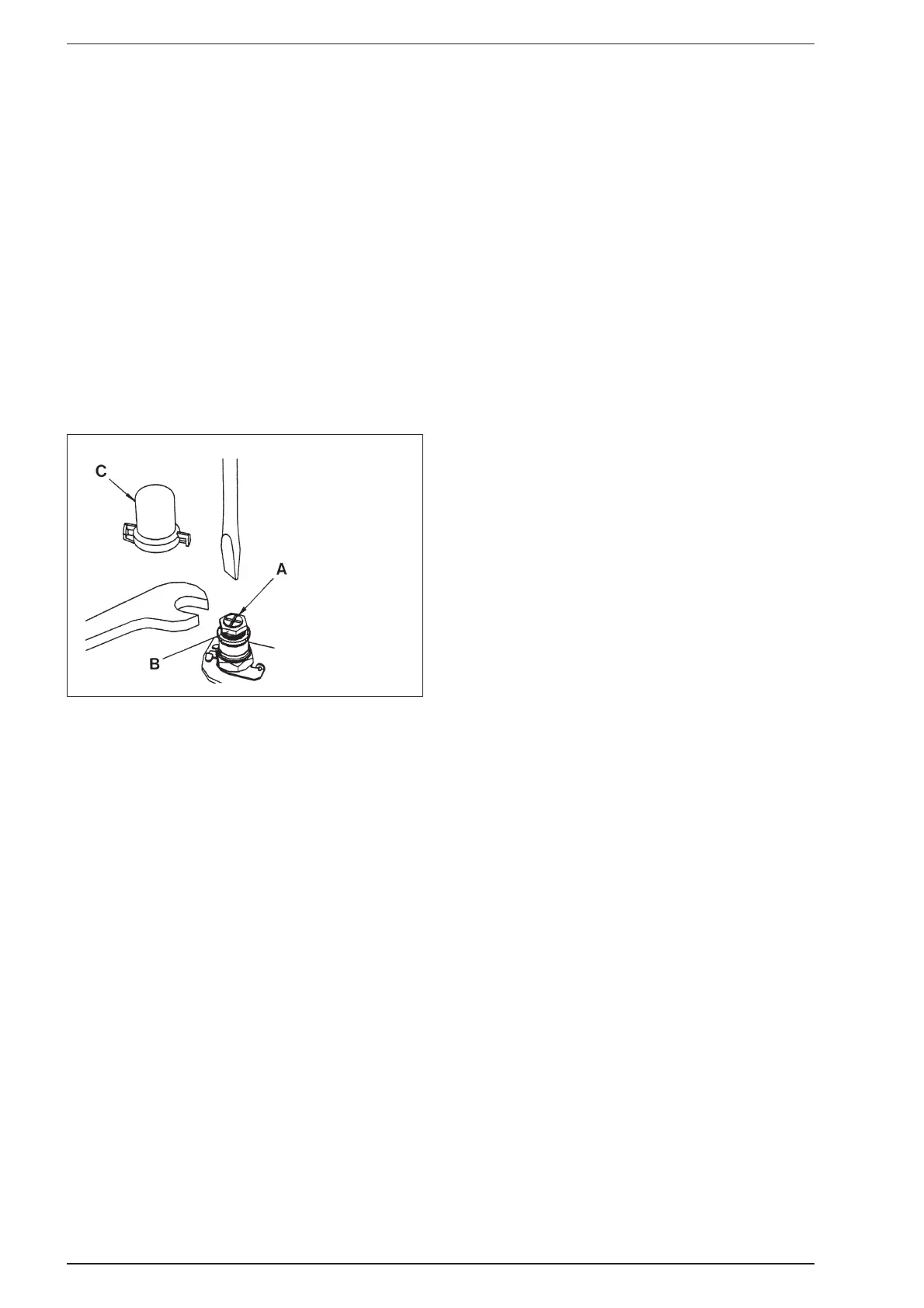

– refit the proportioning unit sealing cap (C fig 28);

– reduce the D.H.W. draw off rate to the minimum

necessary to maintain the burner alight by carefully

adjusting the D.H.W. Inlet valve and check that the

burner pressure decreases in response to D.H.W. tem-

perature rise.Fully open the inlet valve;

– close the D.H.W. tap and ensure that the burner is

extinguished and the pump stops.

– Continue as in section 4.3 to 4.5.

8.7 PRESSURE SWITCH

Two types of pressure switch are available on this

appliance, HONEYWELL or HUBA. Both are fully inter-

changeable, and figs. 21 - 22 shows the differences

between them. Note that the HUBA switch has a

bracket not required by the HONEYWELL switch.

– Remove the outer casing and the sealed chamber front

panel as described in section 5.1.

– Disconnect the pressure sensing pipes from the switch

(fig. 20).

– Disconnect the electrical connections from the switch.

– Unscrew and remove the two screws securing the moun-

ting bracket (HUBA) or switch body (HONEYWELL).

– (HUBA only) Remove the switch from the bracket (two

screws) and fit the new one.

– Fit the new switch and re-assemble in reverse order

referring to figs. 21 - 22 and the wiring diagrams (sec-

tion 7) as appropriate.

8.8 LIMIT THERMOSTAT

The limit thermostat is situated on the top, L.H.S. of the

heat exchanger (19 fig. 24).

– Remove the outer casing and the sealed chamber front

panel as described in section 5.1.

– Without disconnecting the wires, unscrew the two limit

thermostat fixing screws.

– Lift the thermostat and fixing screws out using the wires.

– Replace the thermostat and spread heat sink compound

(supplied) over the base of the new one.

Connect the wires, (polarity is immaterial) and position

the screws in the flange and re-fit using the wires to

position the thermostat before tightening the screws.

– Re-assemble in reverse order.

8.9 THERMOCOUPLE AND OVERHEAT

THERMOSTAT FOR “FRIENDLY” MODEL

– Remove the combustion chamber front panel as descri-

bed in section 5.1.

– Loosen thermocouple retaining nut at pilot burner and

pull out thermocouple.

Work thermocouple through plastic grommet at the

base of combustion chamber.

– Remove the two screws retaining overheat thermostat

(10 fig. 24).

– Unscrew thermocouple from rear of gas valve.

– Replace and reassemble in reverse order.

8.10 OVERHEAT THERMOSTAT

FOR “FRIENDLY E” MODEL

The bulb of the overheat thermostat (10 fig. 24) is positioned

in a phial pocket alongside the air separator in the flow pipe.

– Remove the outer casing as described in section 5.1.

– From below the boiler, unscrew and remove the

overheat thermostat locking nut to release the thermo-

stat body.

– Remove the two screws TCB M4 x 10 (2 fig.14) and

pivot the control box downwards, then remove the two

self tapping screws (1 fig. 14) and remove the control

box cover.

– Withdraw the thermostat then pull off the two electrical

connections

– Remove the lower “key ring” securing the thermostat

phial in its pocket and remove the phial by sliding it

downwards. Withdraw the phial through the grommet

in the control box.

– Re-assemble in reverse order ensuring that the new

phial is coated in heat sink compound (supplied) and

correctly positioned and secured in it’s pocket. Note that

the electrical polarity is immaterial.

8.11 THERMISTOR - C.H. OR D.H.W.

The thermistors are screwed in fittings on the flow pipe

(C.H.) and D.H.W. outlet pipe (D.H.W.).

The thermistors do not penetrate the waterways, therefore

it is not necessary to drain the appliance (fig. 24).

– Remove the outer casing as described in section 5.1.

– Pull off both electrical connections from the faulty ther-

mistor, unscrew the thermistor, replace and re-assemble

in reverse order using the heat sink compound supplied.

Note that the polarity of the thermistor connections is

immaterial.

The sensors are NTC mod. ST03 ones and are inter-

changeable.

Table 9 shows the resistance values that are obtained on the

sensors as the temperature varies.

27

KEY

A Plastic screw

B Nut

C Sealing cap

Fig. 28

Loading...

Loading...