ZB2044December 2007

Page 27

TM

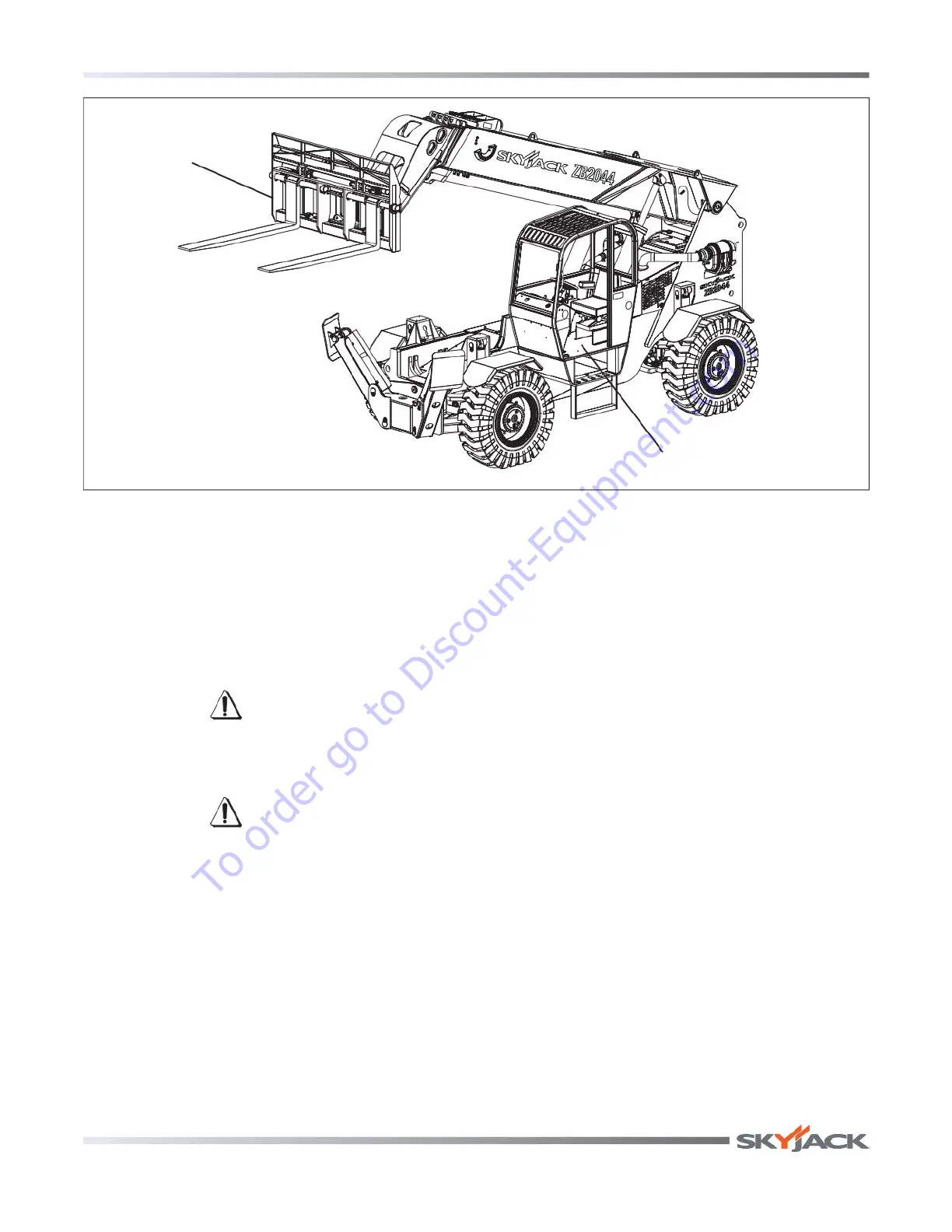

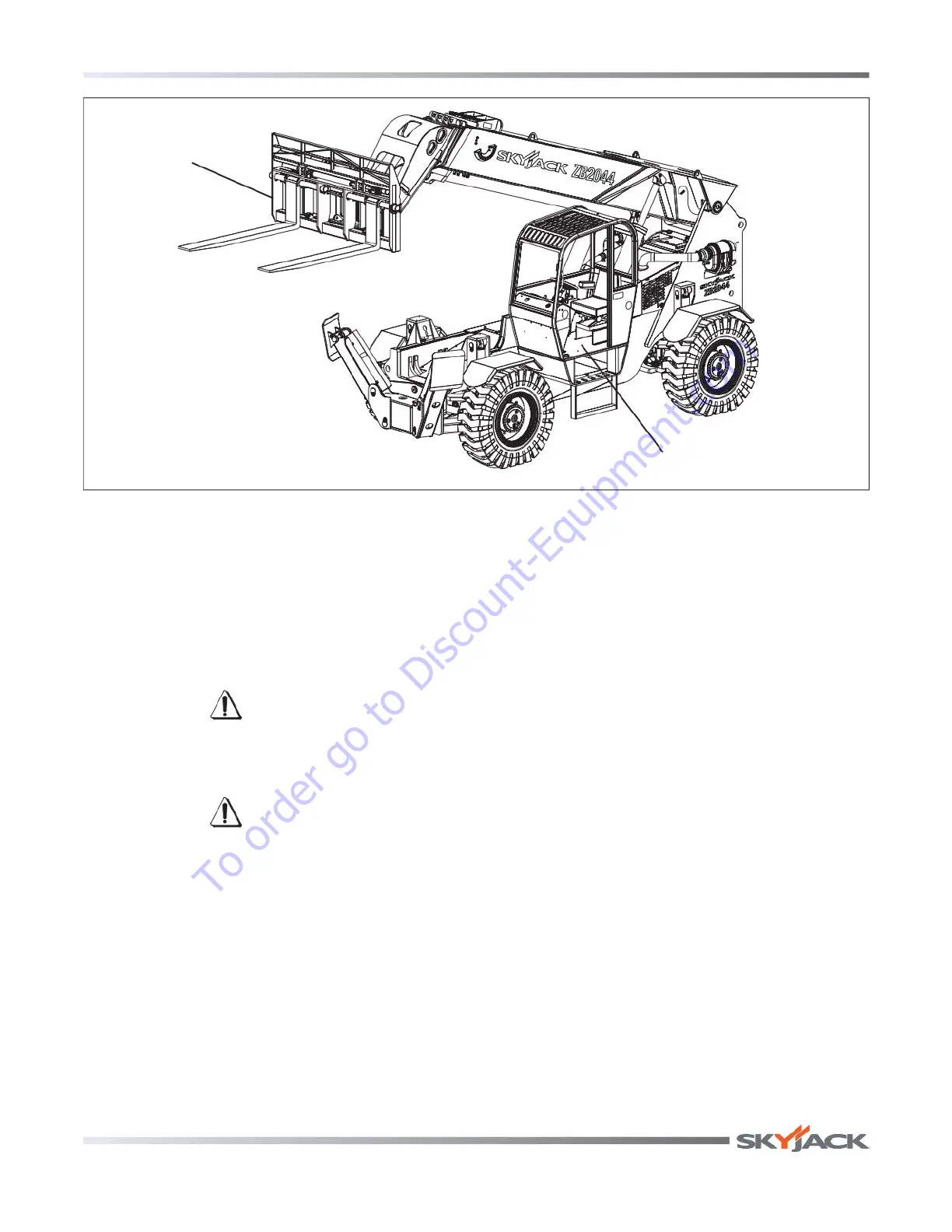

Section 2 - Operation Visual and Daily Maintenance Inspections

2.8 Visual & Daily Maintenance

Inspections

Before performing the visual and daily maintenance

inspections, ensure that the telehandler is parked on a

rm level surface.

Begin the visual and daily maintenance inspections

by checking each item in sequence for the conditions

listed in this section.

WARNING

To avoid injury, do not operate a

telehandler until all malfunctions have

been corrected.

WARNING

To avoid possi ble in jur y, en sur e

telehandler power is off during your visual

and daily maintenance inspections.

NOTE

While performing visual and daily

inspections in different areas, be aware

to also inspect all switches, electrical and

hydraulic components.

2.8-1 Labels

Refer to the labels section in this manual and determine

that all labels are in place and are legible.

2.8-2 Electrical

Maintaining the electrical components is essential to

good performance and service life of the telehandler.

• Ensure proper operation of all gauges

• Check charging system Ammeter/Voltmeter

• Inspect the following areas for chafed, corroded

and loose wires:

• boom wiring harnesses

• frame wiring harnesses

• cab wiring harnesses

Ensure electrical devices are properly secured with no

signs of visible damage. Ensure there are no loose or

missing parts.

2.8-3 Safety Switches

Ensure safety switches are properly secured with no

signs of visible damage.

2.8-4 Mirrors

Ensure mirrors are properly secured with no signs of

visible damage.

Attachment

Operator’s

Cab

To order go to Discount-Equipment.com

Loading...

Loading...