ZB2044December 2007

Page 33

TM

Section 2 - Operation Visual and Daily Maintenance Inspections

Grease Points on Frame

1. Ensure telehandler is on a rm level surface

and is in stowed position.

2. Locate grease ttings (refer to label inside

operator’s cab) and pump grease in the

following:

- axle pivot bearings (front and rear)

- axle lock cylinder (top and bottom)

- lift cylinder (top and bottom, both sides)

- frame level cylinders (top and bottom)

- outrigger pins

- slave cylinders (top and bottom)

3. Using a creeper, slide under the frame to

locate grease ttings and pump grease in

the following:

- drive shaft U-joint (front and rear)

- slip joint on drive shaft (front and rear)

Grease Points on Boom Assembly

1. Ensure telehandler is on a rm level surface

and is in stowed position.

2. Locate grease ttings (refer to label inside

operator’s cab) and pump grease in the

following:

- main boom pivot bearing pins

- retract chain rollers

- hose rollers

- extension chains and rollers

- slide pads

- attachment tilt cylinders (top and bottom)

- attachment pivot bearings

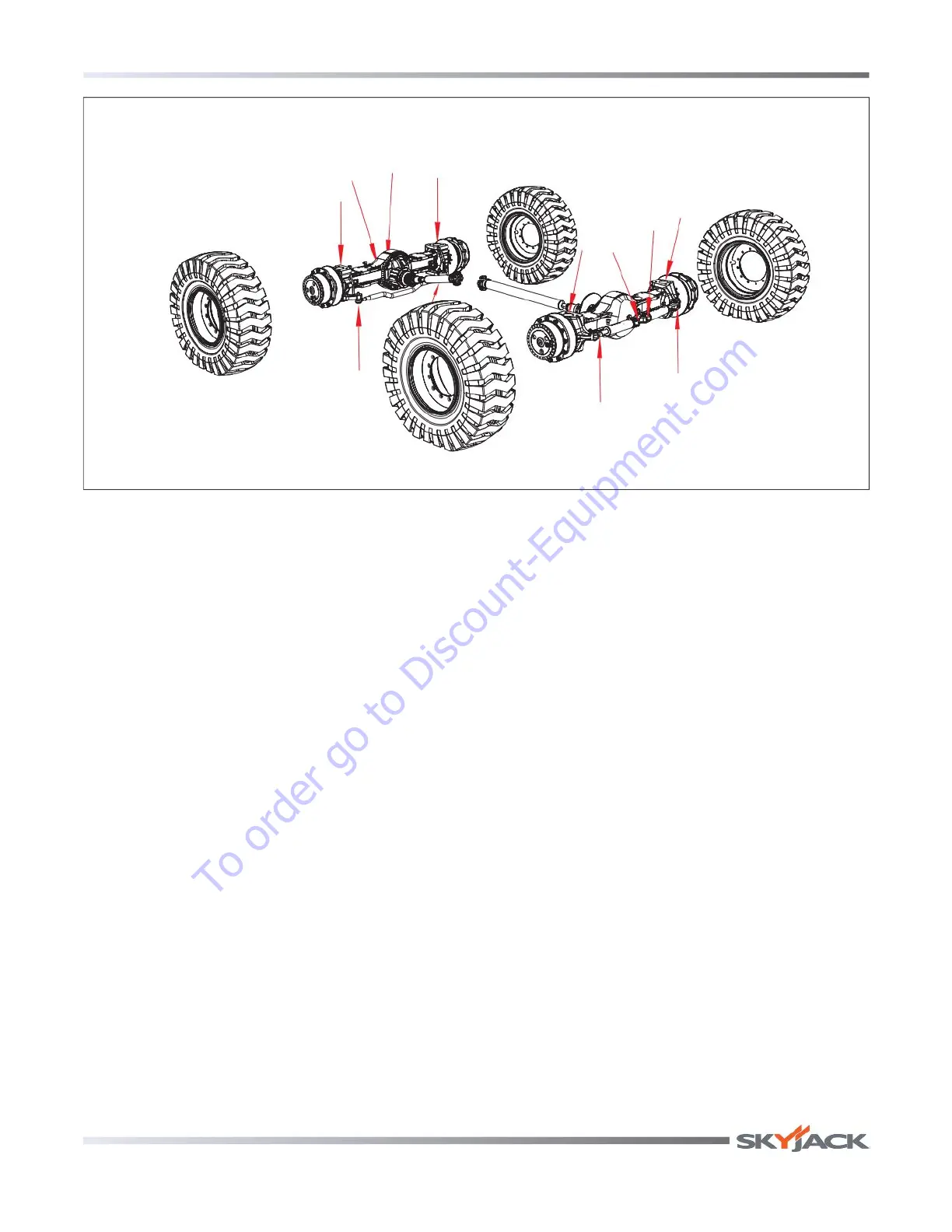

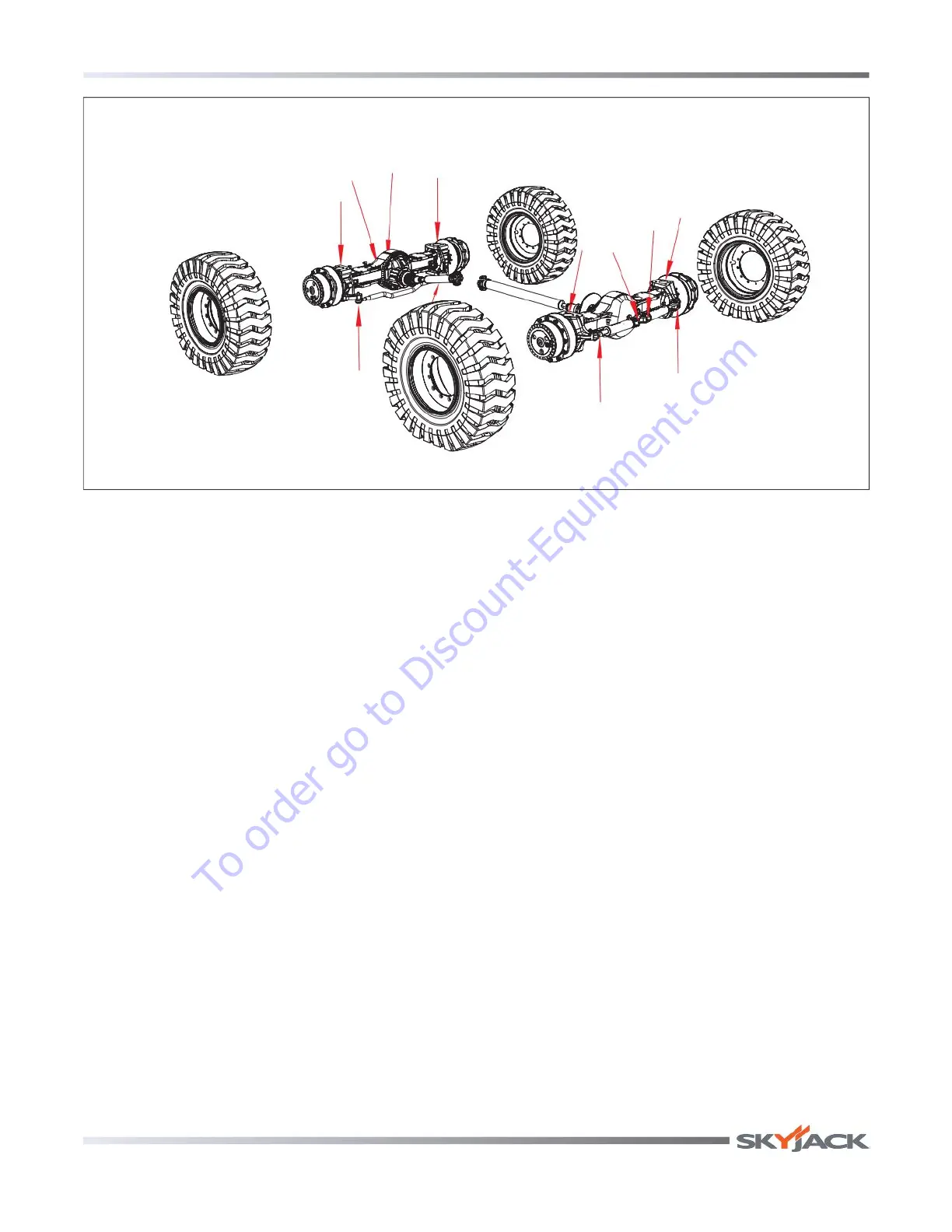

Axle Grease

Points

To order go to Discount-Equipment.com

Loading...

Loading...