17

3059

23 2024

-

PJC 221 & 222

Hold Calibration

Menu System Information

Information - PPC, SR150000, SR61242

Joystick Calibration

MC_0098

MC_0098

MC_0098

MC_0098

Setup

Default in systems

without stabilizers

Calibrates the HOLD-function to get balanced thrust from the bow and stern thruster. If only one

thruster or PJC221/PJC211 you will not get any balanced thrust, but you can adjust the maximum

thrust from HOLD buttons. Hold-button represents 1/6 of the calibrated value.

(NB: HOLD CALIBRATION is not available until SETUP is completed.)

To start calibration, press the “+”-Hold button in the desired direction. For a fi rst time calibration, the thrusters

will start at 70%. A system previously calibrated will start with the last amount of thrust set.

Adjust power with the joystick.

Press the button below to save the calibration values.

Press the button below to cancel calibration without saving.

(NB: Setup calibration in one direction sets values for both directions.)

THRUSTER INFO

Display info about the thrusters in the system.

The number of thrusters/controllers found is

shown in the upper right corner of the display.

The list of devices found can fi ll more than one screen. A scroll bar indicates the position of the selected item.

The joystick(s) operates the thrusters as normal while info is displayed. This will be useful for troubleshooting,

service and general system diagnostics. List will only show devices present on the S-link.

PPC DC Speed Controller

SR150000 Retract controller

SR61242 Retract controller

Motor Temp: Temperature measured at the electric motor brushes

(Not implemented in SR61242)

Contr. Temp: Temperature measured inside the controller

(Not implemented in SR61242)

Voltage: Motor Voltage measured at the controller

Thrust: Thrust level from joystick/hold buttons

°/A/kW: Retract angle (SR150000) / Motor Current (PPC) / Power reading (PPC). SR150000 retract angel is 0°

when fully deployed, and about 90° when retracted. Put SR150000 in service mode and operate the

controller manually in an out to read the two end position angels for service and installation.

(only for PJC2xx panels with HW V2)

This function is for calibrating the joysticks, and requires a pin code to enter. This option is for service personnel

only.

INFO

• Move between menu items with the (stern) joystick.

• Press the button below to select the highlighted menu entry.

• Press the button below to return to the previous menu.

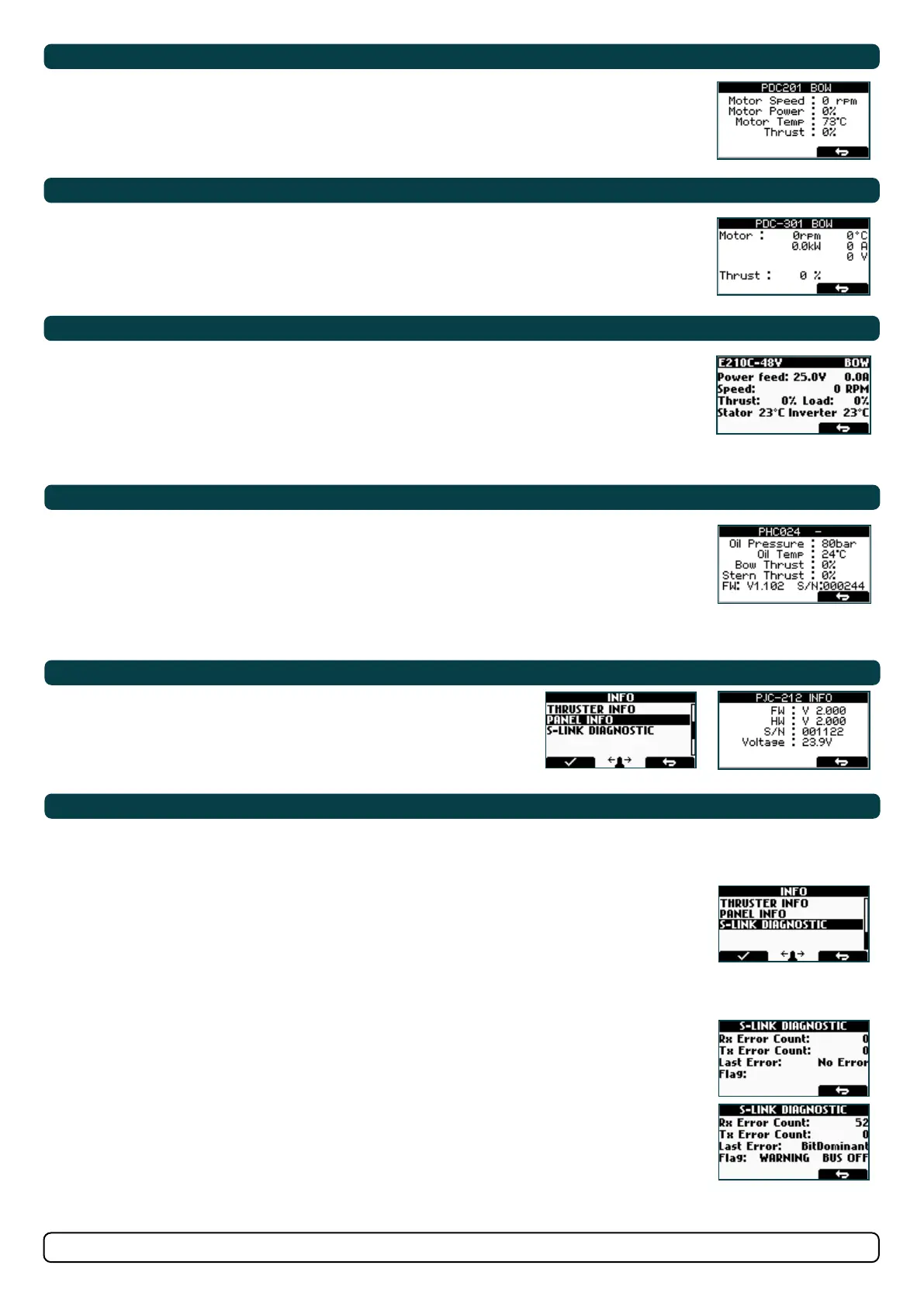

Information - PDC 101 & PDC 201

MC_0098

MC_0098

MC_0098

PDC 101 and PDC 201 (Controller for AC electric thrusters)

Motor Speed: RPM on motor output shaft

Motor Power: Motor power consumption in % (PDC 201 only)

Motor Temp: Temperature measured in motor

Thrust: Thrust level from joystick/hold buttons

PDC-301 (SAC controller)

Motor : speed (rpm), temperature (°C/°F), power (kW), AC current (A) & AC voltage (V).

Thrust: Joystick thrust (%)

eVision and EHP

At the top: eVision Product Number e.g. E210C-48V and Instance e.g. BOW

Power feed: Input Voltage and Motor Current

Speed: Motor speed in RPM

Thrust: Output thrust in % Load: Motor Load in % of nominal torque

Stator: Temperature Inverter: Temperature

Information - PDC-301

Information - eVision & EHP

Information - PHC-3 & PHC024

MC_0099

PHC-3 and PHC024 (Controller for hydraulic thrusters)

Oil Pressure: Oil pressure measured at system oil tank

Oil Temp: Temperature measured inside the oil tank

Bow Thrust: Thrust level from joystick/hold buttons

Stern Thrust: Thrust level from joystick/hold buttons

FW: Version number, Firmware

S/N: Serial number of the PHC

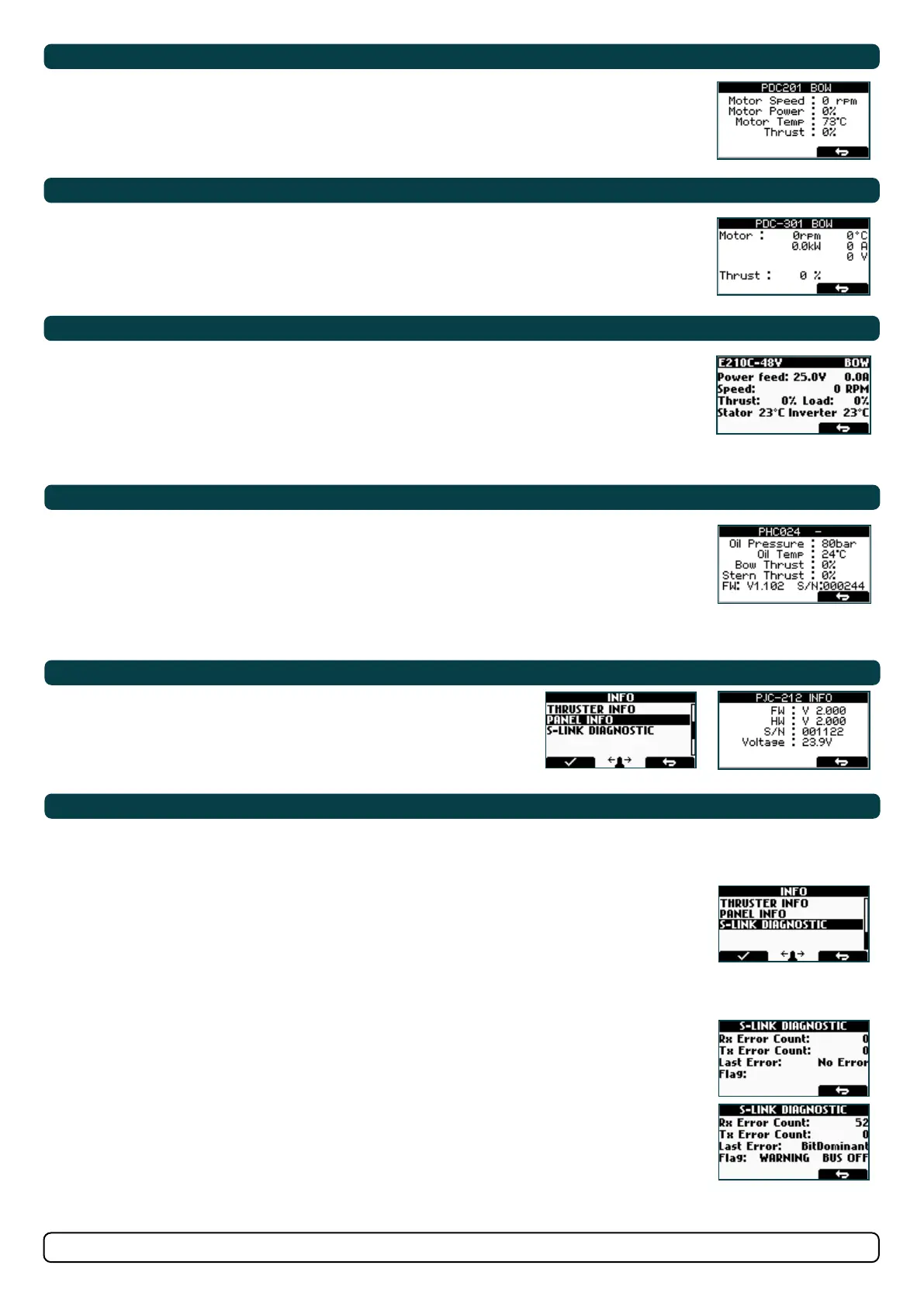

Panel Information

MC_0100

Display info about the control panel

FW: Version number, Firmware

HW: Version number, Hardware

S/N: Serial number of the control panel

Voltage: S-link system voltage measured at the panel

• Shows live update of S-link bus (CAN-bus) error status for the panel.

• Showing no error and signal condition is good.

• Example showing lots of error and very bad signal conditions.

DIAGNOSTIC DISPLAY

Rx Error Count

Receive error counter. Error during reception increments the value. After every successful reception the

value is decremented.

Tx Error Count

Transmit error counter. Error during transmit increments the value. After every successful transmit the

value is decremented.

Last Error

Indicates the error condition of the last error detected. If a message has been transferred or received

without error, it will show No Error.

Conditions: No Error, STUFF, FORM, ACK(Acknowledgment), BitRecessive, BitDominant & CRC.

Flag

BUS OFF: when Tx Error Count is greater than 255 and overflowed. (Tx Error Count will show 0 when in

BUS OFF state)

WARNING: when Rx Error Count or Tx Error Count has reached 96 counts

PASSIVE: when Rx Error Count or Tx Error Count is more than 127 counts

(NB: When S-link devices are hot plugged or disconnected to the bus or powered (when AMS is engaged

and powering PPC and retract), it is not unusual to see some values been incremented. But they will

quickly decrement to 0 again. This will not cause any communication issues.)

S-Link Diagnostic

MC_0100

Loading...

Loading...