25

3059

23 2024

-

PJC 221 & 222

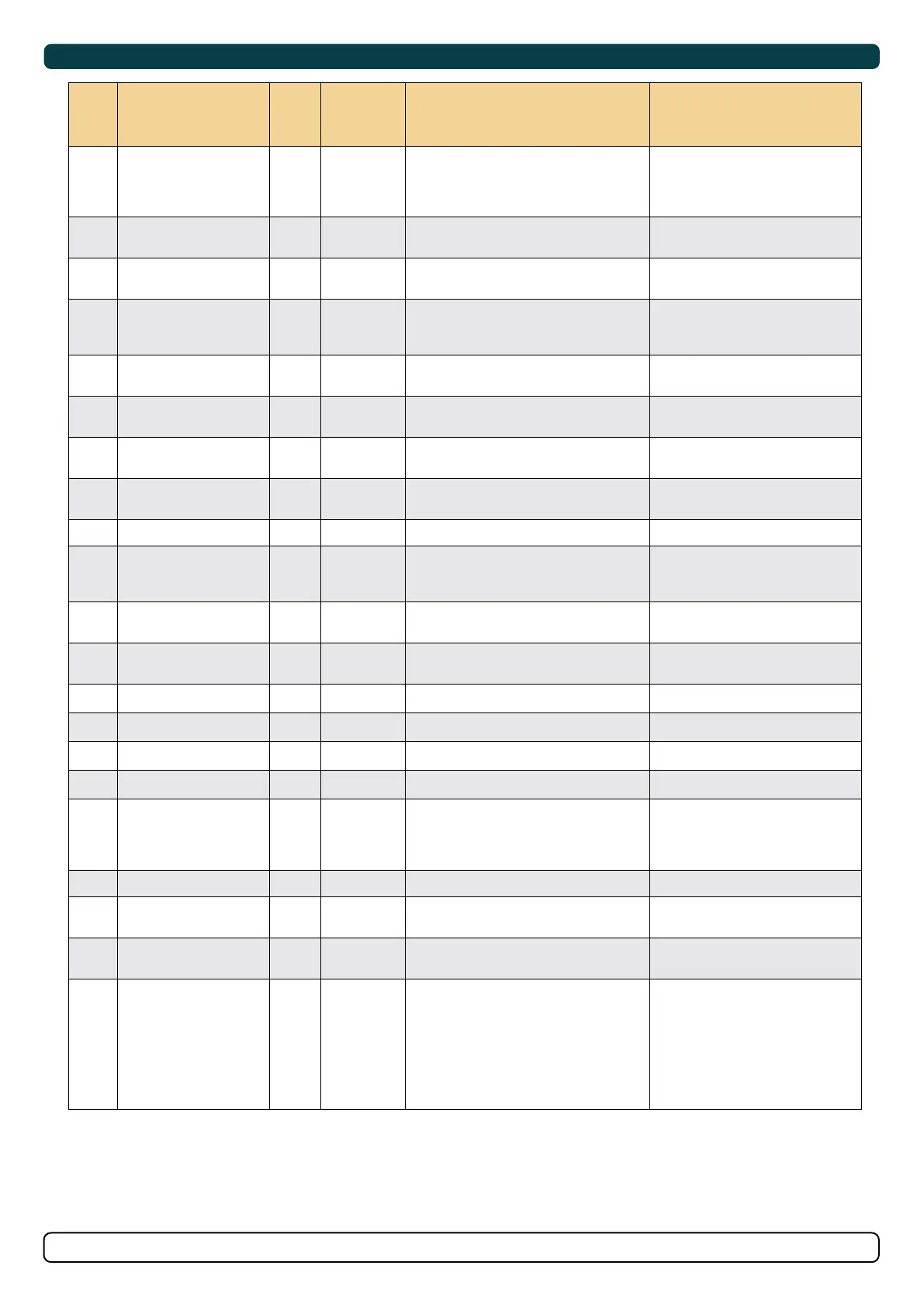

Alarm Descriptions

MC_0053

1. PPC520, PPC820, PPC800, PPC840

2. Buzzer is only activated when any device is sending thrust on the S-link bus.

"Err.

No."

Errors shown in display

"Auto

Reset"

"Ext. buzzer

activation at

Alert Level"

Description Action

1 Motor Overcurrent

2

(

²

)

, 3 Motor current too high. "Thruster must be serviced by

authorized personnel, reset or power

OFF/ON PPC

(

¹

)

."

2 Motor Overtemp

Yes 2

(

²

)

, 3 "Motortemp has been over

120°C/248°F."

Motor cool down below 110°C /230°F.

3 Controller Overtemp

2

(

²

)

, 3 "PPC

(

¹

)

temp has been over

80°C/176°F."

PPC

(

¹

)

cool down below 45°C/113°F.

4 Controller Overtemp

2

(

²

)

, 3 "SR150000 temp has been over

80°C/176°F."

SR150000 cool down below 45°C

/113°F.

5 Low Voltage

2

(

²

)

, 3 Low motor voltage alarm when motor

is running.

12V thruster below 8.00V

24V thruster below 12.00V

Recharge battery, reset or power OFF/

ON device.

6 Thermoswitch

Yes 2

(

²

)

, 3 Thermo switch input is activated and

there is an open circuit.

The thruster needs to cool down before

operating again.

7 IPC Error

2

(

²

)

, 3 Motor relay fault "Turn off thruster battery main switch.

Thruster must be serviced by authorized

personnel."

8 Critical Error

2

(

²

)

, 3 PPC

(

¹

)

output fail PPC

(

¹

)

must be sent for service.

9 Low Motor Current

2

(

²

)

, 3 Thruster uses no power Check thruster connections or motor

dead!

10 Motor Contactor

2

(

²

)

, 3 No current on motor relay coil. Check motor relay connections, short

circuit or relay dead!

11 System Error

2

(

²

)

, 3 Fatal error Device must be serviced by authorized

personnel

12 No Communication

2

(

²

)

, 3 No communication with device Check S-Link cables and power

connections.

13 Motor Temp Sensor

2

(

²

)

, 3 Motor temperature sensor fail Check for an open circuit on the temp

sensor on the motor

14 Supply Voltage Fault

2

(

²

)

, 3 No power Check power connections

15 Fuse Blown

2

(

²

)

, 3 Fuse blown Replace fuse or check if main cable from

battery and main cable to thruster has

been switched

16 Manual Override

Yes 2

(

²

)

, 3 Main switch manually overridden Pull main switch

17 Motion OUT Fault

2

(

²

)

, 3 Retract obstructed while deploying Turn off all panels. Go for lower speed/

deeper water and retry.

18 Motion IN Fault

2

(

²

)

, 3 Retract obstructed while retracting Turn panel on and manually override

main switch. Remove obstruction and

try again.

Below are Generic Fault Codes listed. For legacy reasons this system is used on old products and products with old fi rmware versions.

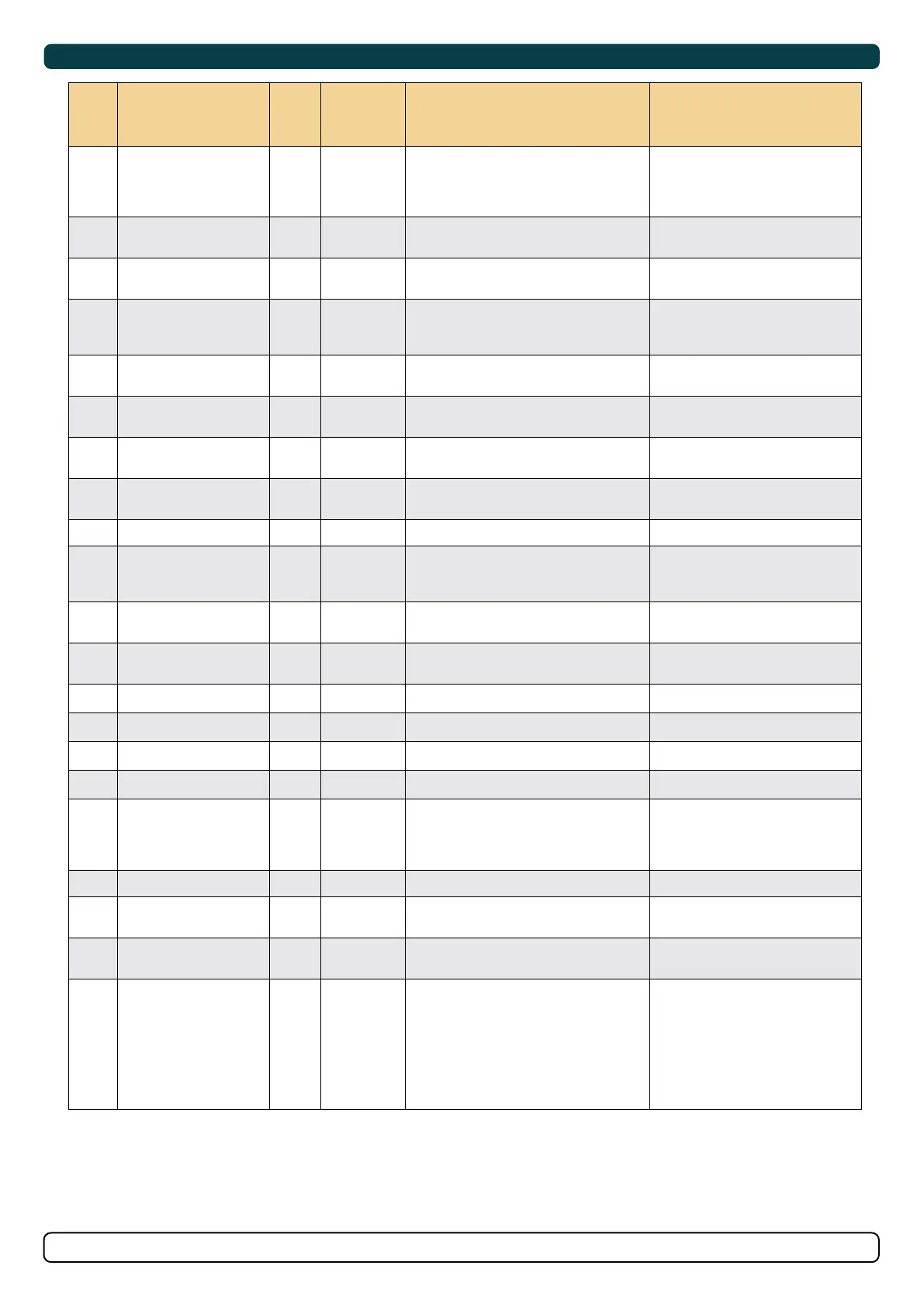

Alarm Descriptions

MC_0053

1. PPC520, PPC820, PPC800, PPC840

2. Buzzer is only activated when any device is sending thrust on the S-link bus.

"Err.

No."

Errors shown in display

"Auto

Reset"

"Ext. buzzer

activation at

Alert Level"

Description Action

19 Actuator Fault 2

(

²

)

, 3 Actuator not getting any power "Check actuator connection or power

to actuator. Reset alarm in alarm

menu on PJC 211/212/221/222 or

recycle power."

20 Pos.Sensor Fault 2

(

²

)

, 3 Retract position sensor fail Check position sensor cables and for

sensor damage.

21 In Service Mode Yes 2

(

²

)

, 3 "Retract controller in service mode. Switch

no. 4 is ON."

Check dip switch setting on retract

control box.

22 High Oil Temp Yes 1, 2

(

²

)

, 3 "Hydraulic oil temperature is higher than

75°C /167°F."

"Stop running and wait for

temperature to drop.

Check if cooling pump is running."

23 Low Oil Level 1, 2

(

²

)

, 3 Hydraulic oil level is to low Fill more hydraulic oil to the

hydraulic tank.

24 Warning Return Filter Yes 2

(

²

)

, 3 Return fi lter element required

replacing.

25 Warning Pressure Filter Yes 2

(

²

)

, 3 Pressure fi lter element required

replacing.

26 Warning High Speed Yes 1, 2

(

²

)

, 3 "WARNING! High Speed.

Stabilizer not active!"

27 Stabilizer Fault Yes 1, 2

(

²

)

, 3 Any Stabilizer alarm. See stabilizer panel for more info.

28 AC Motor Overtemp Yes 1, 2

(

²

)

, 3 "Hydraulic AC motor power pack overtemp.

Higher than

120°C/248°F."

Stop running and wait for

temperature to drop.

29 AC Motor Sensor Fail 2

(

²

)

, 3 "Hydraulic AC motor power pack temp

sensor open circuit"

Check sensor cables.

30 Temperature Warning Yes 2

(

²

)

, 3

(

²

)

High temperature warning. Warns that the motor temperature is

getting high.

31 Motor Overtemp Yes 1, 2

(

²

)

, 3 High temperature Alarm. See SAC manual for more details.

32 VFD Warning Yes 2

(

²

)

, 3 There is an warning from VFD. Check VFD for more details.

33 VFD Not Ready Yes 2

(

²

)

, 3 The VFD is not ready. Check VFD for more details.

34 VFD Fault 1, 2

(

²

)

, 3 VFD has an Alarm. Check VFD for more details.

35 Warning Low Voltage Yes 2

(

²

)

, 3

(

²

)

Low motor voltage warning when motor is

running.

12V thruster below 9.30V

24V thruster below 17.50V

36 Not Calibrated Yes 2

(

²

)

, 3 Shaft Not Calibrated See manual for how to calibrate.

37 VFD Com. Fault 2

(

²

)

, 3 No Modbus communication with VFD Check VFD Modbus cables and

power.

38 Cooling Fan Fault 2

(

²

)

, 3 Cooling fan stopped running, or running

too slow

Device must be sent for service

39

Interlock

2

(

²

)

, 3 S-link communication between PPC and

retract controller are missing

-Check PPC or retract controller has

power.

-Check S-Link connections to PPC

and retract controller.

-Check if not PPC or SR150000/

SR61242 is wrongly setup as SRP or

SRVP/SRLP.

S-Link Fault Codes

MC_0472

Fault situations in S-Link compliant products generates Fault Codes which are broadcasted on the S-Link bus. If a control panel receives a Fault Code,

it will trigger an alarm in the control panel and the user will be able to get information about which product that reports the fault and the reason for the

fault. Please see the user manual of your S-Link compliant control panel for more information on how to access Fault Code information in case of an

alarm situation.

All Sleipner S-Link compliant products have product specifi c Fault Codes. For legacy reasons some control panels display Generic Fault Codes for

certain products.

Loading...

Loading...