Operation Manual

7

Connecting the PME-500-TR to the breaker

The PME-500-TR connects to the circuit breaker under test by means of four multi-pole

connectors. The first three (Coil Control, Main Contacts and Auxiliary Inputs) are

duplicated with equivalent banana-type connectors in case any of the supplied multi-wire

leads is lost or damaged. Once you have the instrument correctly wired to the breaker, the

rest of the job is greatly simplified. A brief description of these connections follows.

Wiring the Coil Control circuits

WARNING! Auxiliary voltage inside a circuit breaker can reach

250 Vdc. Be sure that auxiliary supply is disconnected before

manipulating the operation coil circuits of the breaker.

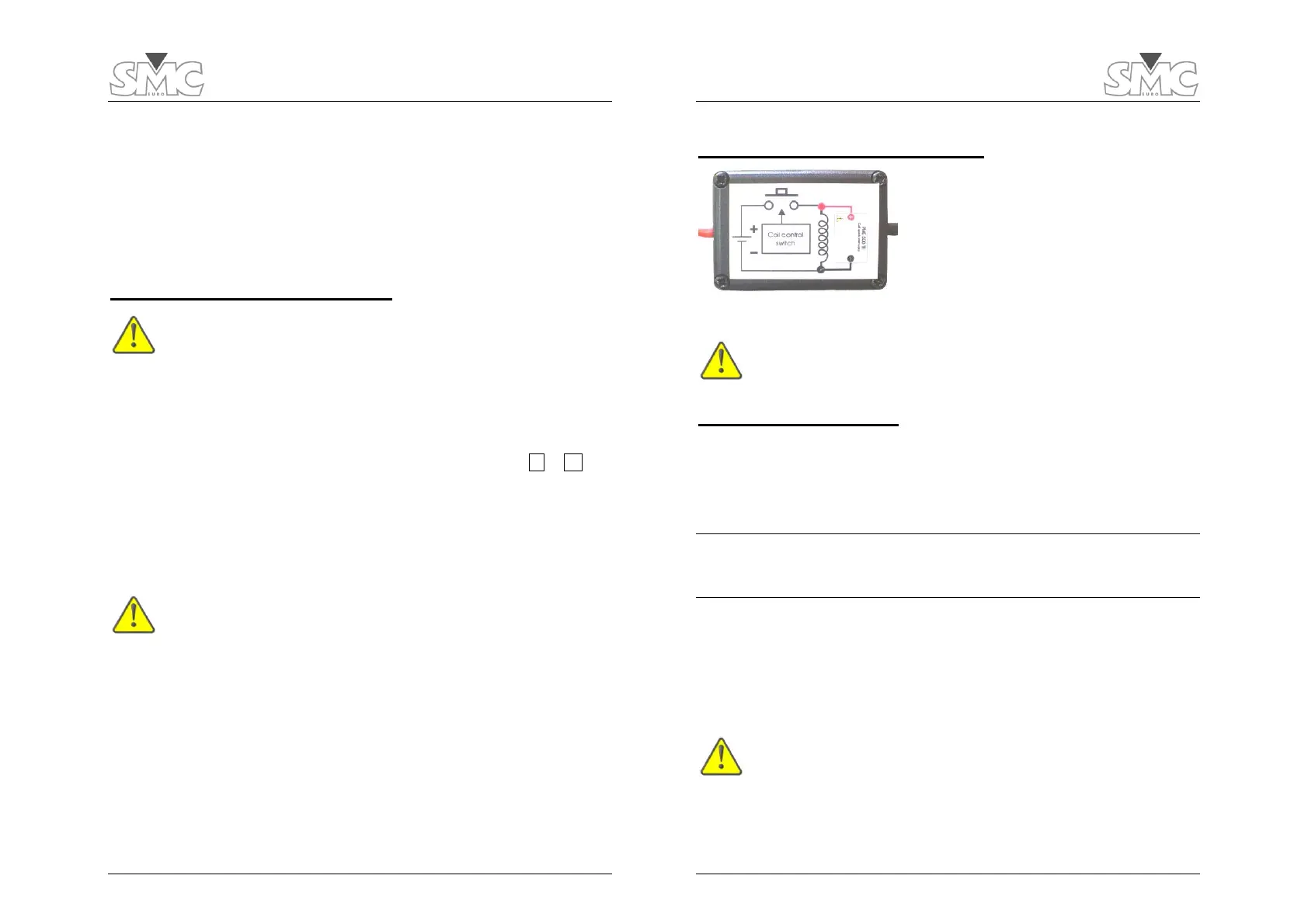

This is the most controversial point of connection for new users. The key to proper cabling

is understanding that two internal solid-state PME-500-TR’s contactors are supposed to

control (rather than to provide) the DC supply circuits of both (Trip and Close) coils of the

breaker. Hence, these contactors must be connected in series with their corresponding

coils and polarity must be respected. Look at the diagram in the instrument’s lid. If you are

breaking at the positive side of the breaker’s coils, then connect each black T or C lead

to its corresponding coil and the blue leads to a point coming from the positive side of the

DC supply. Use the opposite color scheme if you are breaking at the negative side of the

coils. This setup will give TRIP/CLOSE control to the PME-500-TR for easier, faster and

more accurate testing.

The multi-pole connector is duplicated so that standard bananas can be used instead

(black corresponds to negative and green to positive).

DC Polarity to the breaker’s coils must be respected in this

cabling procedure or the control actions from the PME-500-TR

will not be performed at all.

Red LED indicators will be lit instantaneously whenever the PME-500-TR completes the

circuits into which these contacts are inserted.

PME-500-TR

8

Overvoltage protection diodes

To avoid premature wear due to inductive arcing

across the coil control contacts, most

manufacturers install internal protection diodes in

parallel to the operation coils. If the circuit breaker

that you are testing lacks this protection or you are

not sure about its condition, connect the supplied

diodes directly in parallel to the operation coils,

using the same polarity, as shown in the diode’s

label (view figure).

Failure to do this might cause harmful voltage to develop

inside the PME-500-TR when the coil supply circuit is

interrupted during the testing, which will produce serious

damages that are not covered by the equipment’s warranty.

Wiring Main Contacts

The breaker’s main contacts are wired to the PME-500-TR through this connector. Attach

the red “C” terminals to one side of the poles and the black ones to the other side. Use

order 1, 2 and 3 and colors consistently at each pole. If you use the duplicate 4-mm

connectors, you will have to bridge one side of the three poles to make a common point

and connect it to the “Com.” connector.

IMPORTANT NOTICE: WITH GROUNDED BREAKERS – Time and resistance tests are

not possible while both sides of the breaker are connected to ground. You can keep

only one side connected to ground as long as you use the black banana terminals to

the poles on that side, and the red ones to the free poles.

For timing tests, the PME-500-TR injects a low (100 mA) current through the breaker’s

poles using these leads, in order to detect and record changes in the contact status.

For resistance measurement, a 10 A test current is injected using these wires, and the

voltage drop is measured at the terminals of the contact resistance connector (described

later in this section) that should also be wired to the poles for this purpose.

If you accidentally apply any significant voltage to these leads,

one or more internal fuses might be blown. Should this occur,

refer to the troubleshooting section at the end of this manual

for instructions on fuse replacement.

Loading...

Loading...