Operation Manual

9

Using the Auxiliary Inputs

These additional input channels can be used independently for two different purposes:

1) Analyzing the open/close activity of any two contacts inside or related to the circuit

breaker during with the timing test.

2) Detecting contact or voltage changes at any two points inside or related to the

breaker to start the timer and the data recording process. This is called ‘trigger

event’ detection, described in the test setup section.

These inputs are fully isolated from each other and from the earth of the equipment and

have no polarity. Two pairs of LEDs next to the duplicate 4-mm connectors indicate the

mode (dry contact or voltage detection) to which these inputs have been set up as later

described in the Test Menu section. Protection against accidental overvoltage (above 400

V) is provided for these inputs by means of internal fuses. Refer to the troubleshooting

section at the end of this manual for instructions on locating and replacing these fuses.

The auxiliary inputs are commonly used to analyze the breaker’s coil contacts timing with

relationship to the main contacts, but it is also frequent to connect them to some other

points inside the breaker or affected by its operation, like auxiliary contacts or monitoring

points, also for time analysis purposes. However, using these inputs as test initiators is also

a powerful technique when, for example, you cannot drive the breaker from the PTE-500-

TR or you want to refer the time analysis to an electrical event other than the START

command in the instrument. This technique is further described in the Test Execution

section.

Resistance Measurement Connector

As explained before, when resistance measurement is conducted, a 10 A test current is

injected through the main contact connector’s leads and the voltage drop at the contacts

is measured by the leads in this connector.

IMPORTANT NOTICE: WITH GROUNDED BREAKERS – Time and resistance tests are

not possible while both sides of the breaker are connected to ground. You can keep

only one side connected to ground as long as you use the black banana terminals to

the poles on that side, and the red ones to the free poles.

This 4-wire method provides adequate accuracy as long as connections are made firmly

and in the correct order, which is the pole’s contact inside the Res. Measure points and all

this inside the Contacts connections. Phase order (1, 2, 3) and polarity (Red, Black) must

also be consistent between the Main Contact lead set and the Resistance Measurement

terminal set. If you connect the main Contacts leads in between the Res. Measure leads,

you will get a wrong, useless resistance value because this will include the resistance of the

Contacts test leads’ connections.

PME-500-TR

10

Using the optional PME-RESC fast clamps

These clamps may save time and connection errors, as you will have to connect only 6

clamps instead of 12 for timing tests and contact measurement. Plug the black C1 and R1

terminals into a black PME-RESC clamp. Then, do the same with black C2/R2, C3/R3

terminals, and finally use the red PME-RESC clamps in the same way for the remaining red

terminals. You can now connect the red clamps to one side of each pole and the black

ones to the other side, observing the 1-2-3 phase correspondence.

IMPORTANT: Use only the PME-RESC clamps for this simplified connection method,

as these clamps’ arms are isolated from each other. The use of regular clamps with

this method will produce erroneous contact resistance measurements.

Beware that the measured value will correspond to the total resistance between the

connection points used to attach the clamps to both sides of each pole.

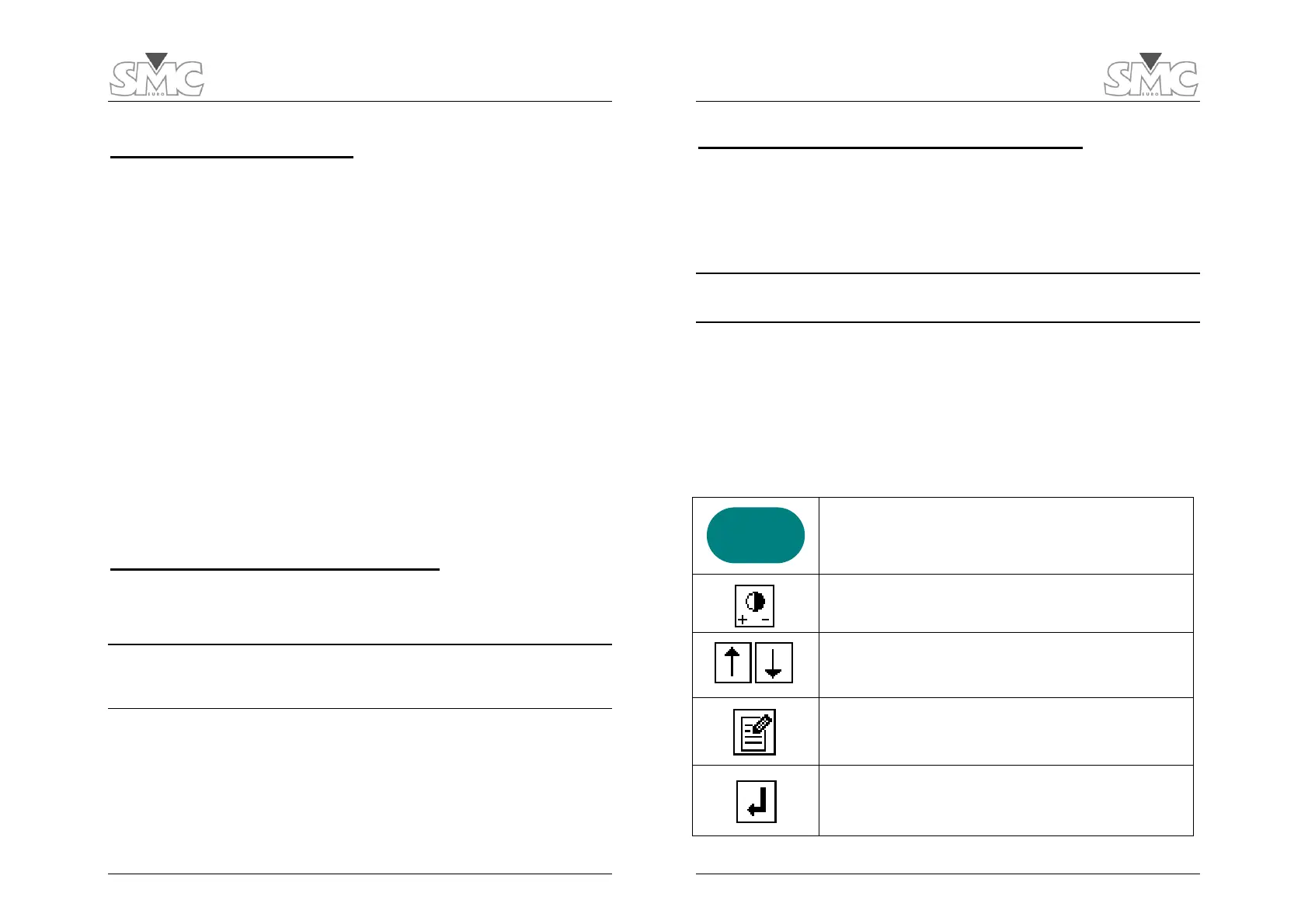

Touch Screen Buttons

All the operation of the PME-500-TR is carried out by means of the ON/OFF switch and

the touch screen buttons in the LCD panel. A description of these buttons follows.

The ON/OFF switch serves two purposes: 1) turning the unit

ON or OFF when held down for a few seconds, and 2) turning

the LCD backlight on and off with a short press.

LCD contrast adjustment. Press and hold to increase the

contrast. Release, then press and hold to decrease… and so on.

Up and Down cursor arrows allow navigation through data

fields, parameter values and menu choices.

Edit Button. Touch it to modify selected data fields or

parameter choices.

Enter Button. Touch it to confirm the setting of a parameter or

a selection from a menu.

ON / OFF

Loading...

Loading...