86/282

7. Maintenance and repairs

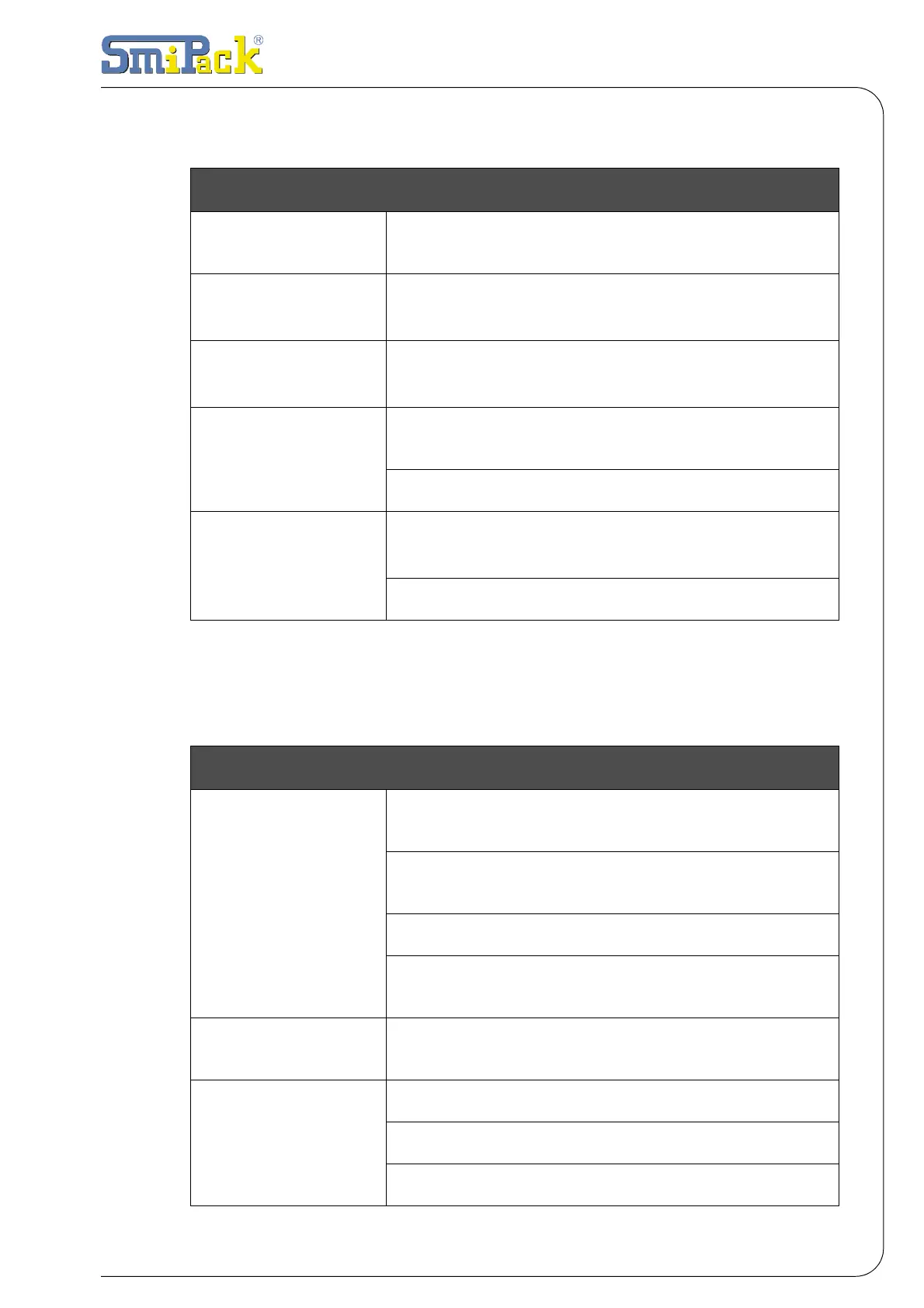

Tab. 7.1.2

WEEKLY MAINTENANCE CHART (60 HOURS OF WORKING)

SEALING UNIT

MAKE SURE THAT THERE ARE NO BREAKAGE ON

THE CUTTING BLADE

ELECTRIC

COMPONENTS

OPEN THE SAFETY DOOR ON THE MACHINE AND

VACUUM THE DEPOSITED DUST

CONVEYOR BELT

UNIT

MAKE SURE THAT THE BELT IS NOT DAMAGED AND

THAT IT IS PERFECTLY TENSIONED

REEL HOLDER

MAKE SURE THAT THE REEL HOLDER IS MOVING

CORRECTLY

CLEAN THE ROLLERS WITH A DRY CLOTH

PUSHER DEVICE

UNIT

MAKE SURE THAT THE PUSHER DEVICE IS SLIDING

PROPERLY

CHECK THE PNEUMATIC PARTS

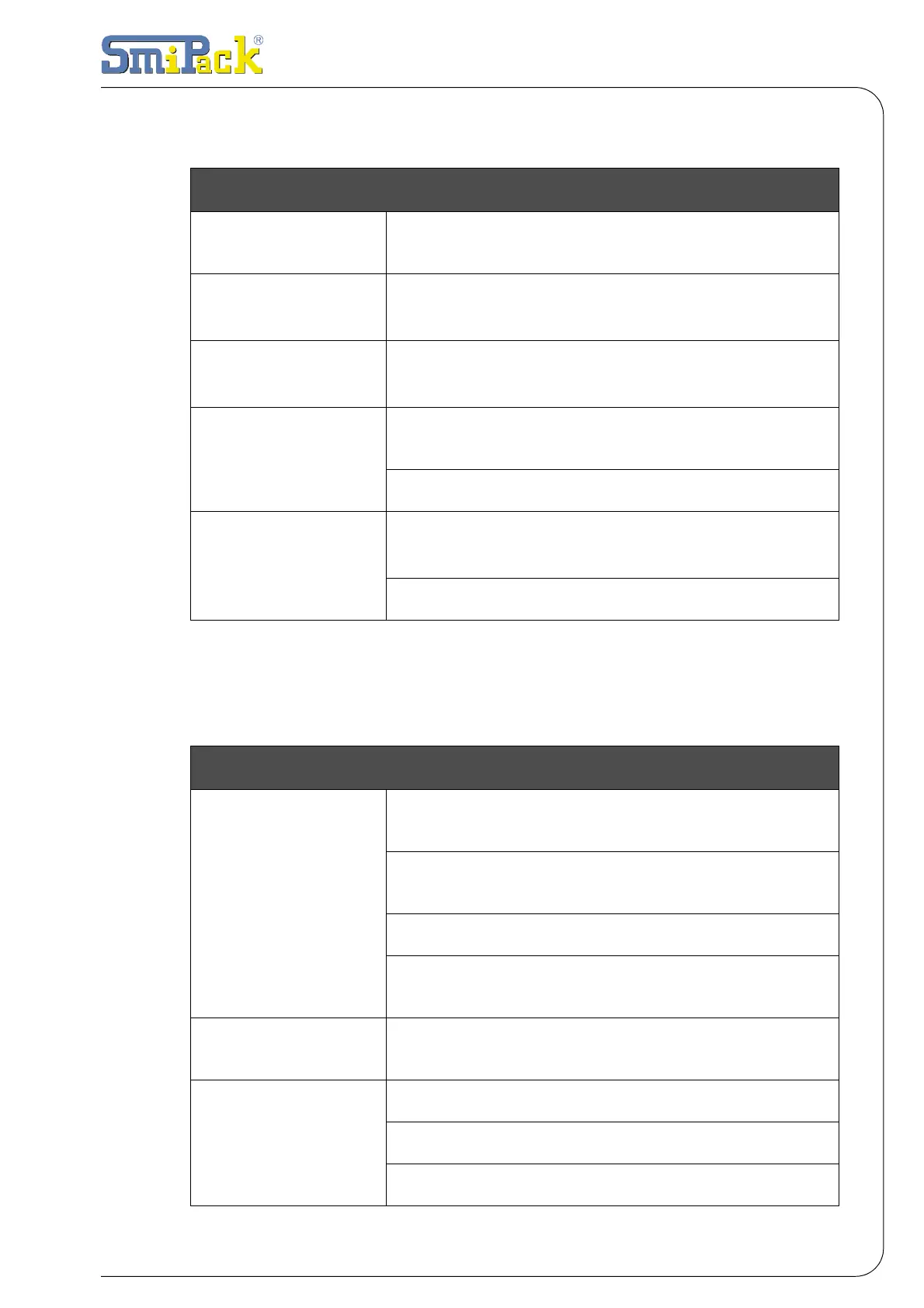

Tab. 7.1.3

MONTHLY MAINTENANCE CHART (240 HOURS OF WORKING)

SEALING UNIT

MAKE SURE THAT THERE ARE NO BREAKAGE ON

THE CUTTING BLADE

CHECK THE WEARING STATE OF THE SILICON

RUBBER

CLEAN AND GREASE THE GUIDES

MAKE SURE THAT THE PNEUMATIC PARTS ARE

WORKING CORRECTLY

PROTECTIONS

CLEAN THE SWITCHES AND THE EMERGENCY

SAFETIES

CONVEYOR BELT

UNIT

TIGHTEN AND ALIGN THE BELT

CHANGE THE BELT IF IT IS WORN

CHECK THE SCREWCOUPLING

Loading...

Loading...