Mechanical Installation 7828 Density Transmitter Technical Manual

2-10 78285000_AB

2.3.3 FREE STREAM INSTALLATION - WELDOLET

This is the preferred option where temperature variations are a critical factor. The

reduced thermal mass of the weldolet's taper-lock fitting renders it more able to track

rapid changes in temperature.

Conditions:

Flow: 0.3 to 0.5m/s (at the transducer)

Viscosity limit: Up to 20 000cP

Temperature: -50°C to 200°C

The weldolet has a 1.5" taper lock fitting, and is supplied to be welded on 4", 6", 8" or 10"

pipelines. Use of the weldolet ensures that the tines of the 7828 are orientated correctly

and are fully inserted into the fluid stream.

Before fitting the weldolet, the pipeline must be bored through at 52.5mm diameter to

accept the viscometer. The weldolet must be welded to the pipeline concentrically with the

pre-bored hole.

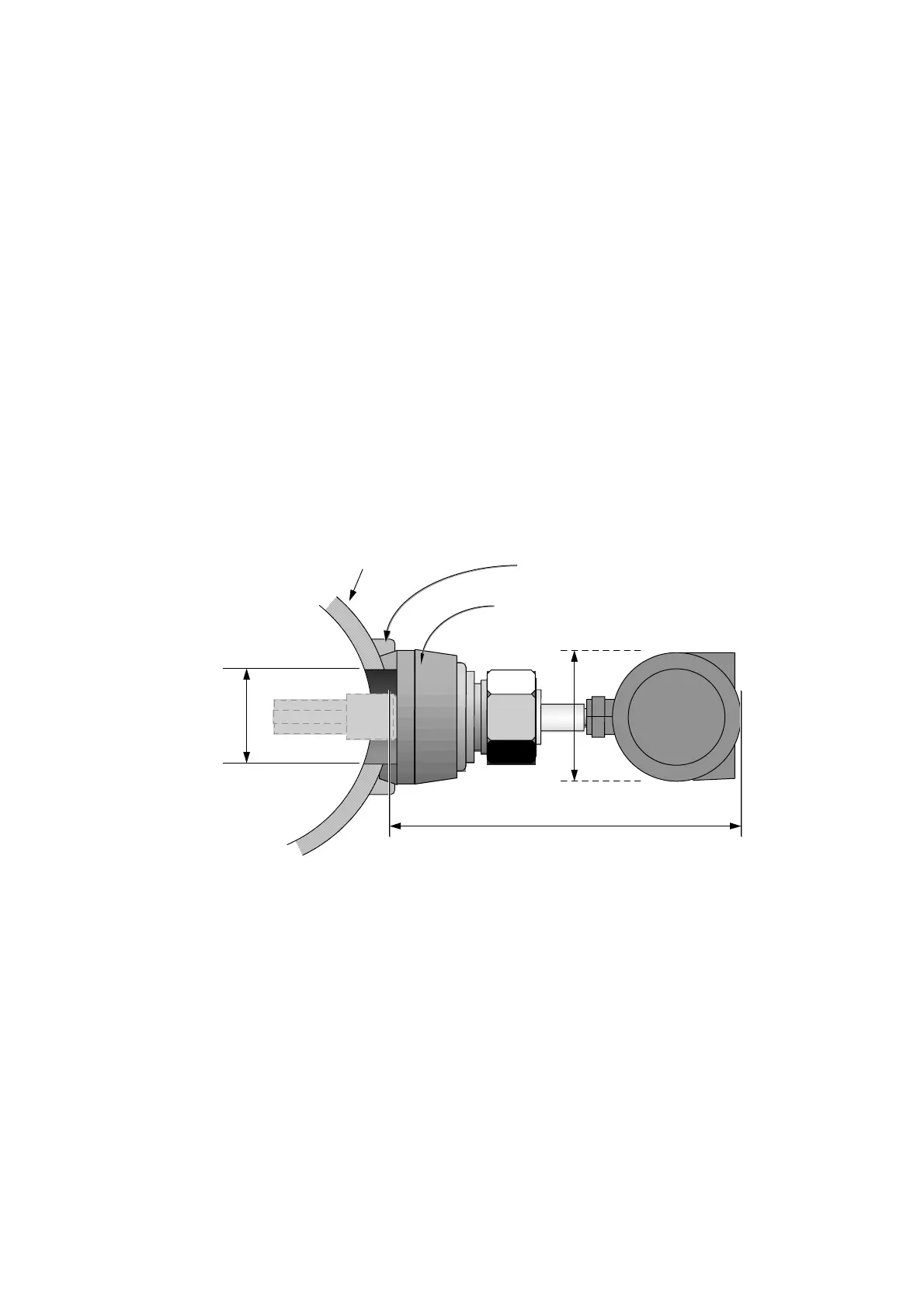

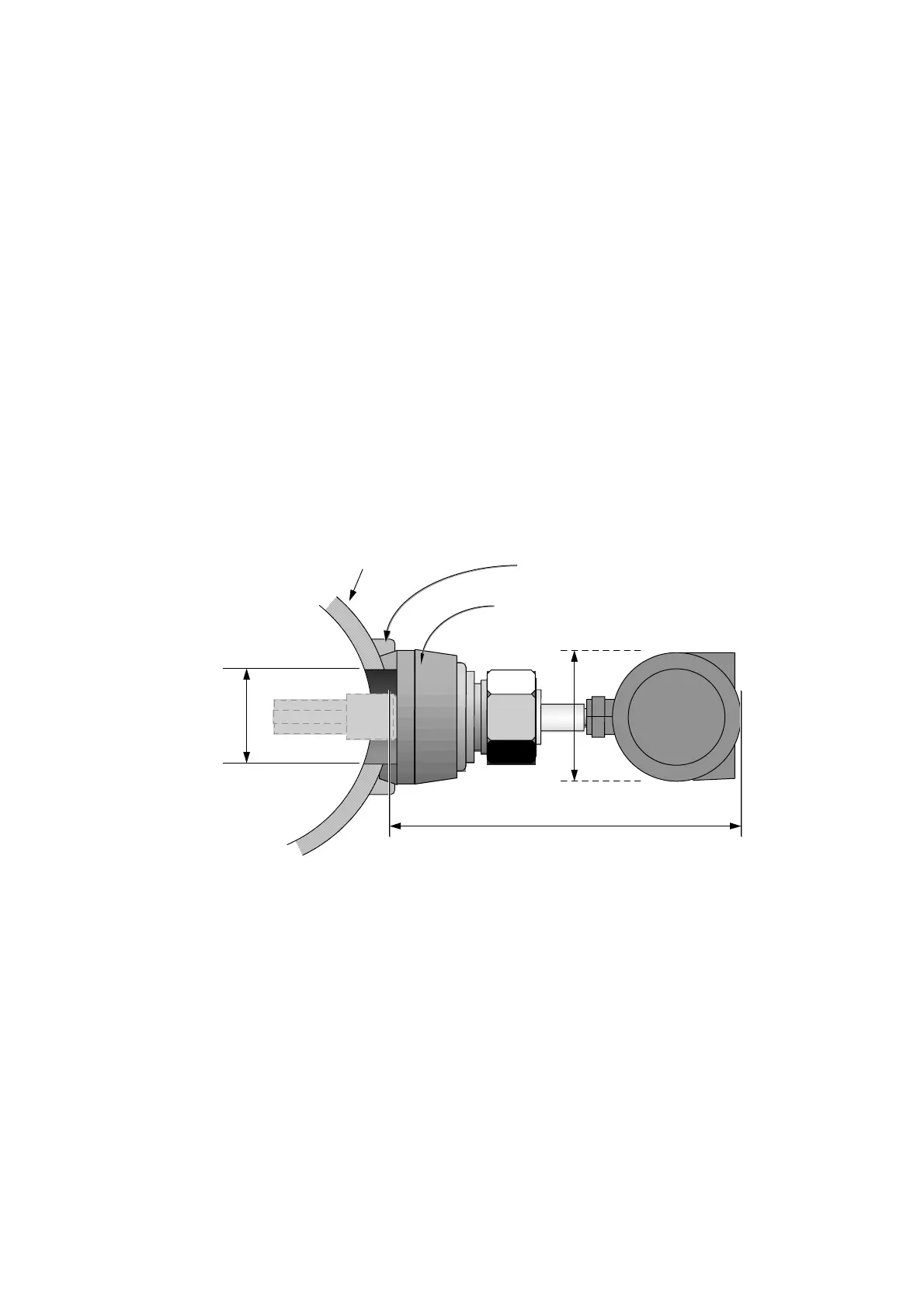

The view shown below is schematic to show the relevant dimensions.

52.5mm

min

254mm

Horizontal: 4” or larger

Vertical: 6” or larger

Weld

111mm

Free stream: 1.5” Swagelok fitting

Free stream weldolet

to suit pipe diameter

(4, 6, 8 or 10” N.B.)

The installation will conform generally to Schedule 40 pressure ratings. The weldolet

fabrication is rated to 100 Bar at ambient temperature.

Note: Correct installation and pressure testing of the fitting is the responsibility of

the user.

Loading...

Loading...