7828 Density Transmitter Technical Manual Mechanical Installation

78285000_AB 2-13

2.3.6 FLOW-THROUGH CHAMBER INSTALLATION

This chamber is fabricated by Solartron, and is available with either weld prepared ends or

with flange or compression fittings for connection into the process pipe lines. It is available

with 1” or 2” inlet and outlet pipes.

Note: The length of the inlet and outlet pipes must not be altered, otherwise the

temperature response and stability of the fitting may be adversely affected.

Conditions:

Flow: constant, between 10 and 30 l/min

Viscosity limit: Up to 20 000cP

Temperature: -50 to +200°C

Pressure: 70 bar at 204°C, subject to process connections.

The PT100 is a direct insertion type, without a thermowell, and uses a ¾" Swagelok

connection.

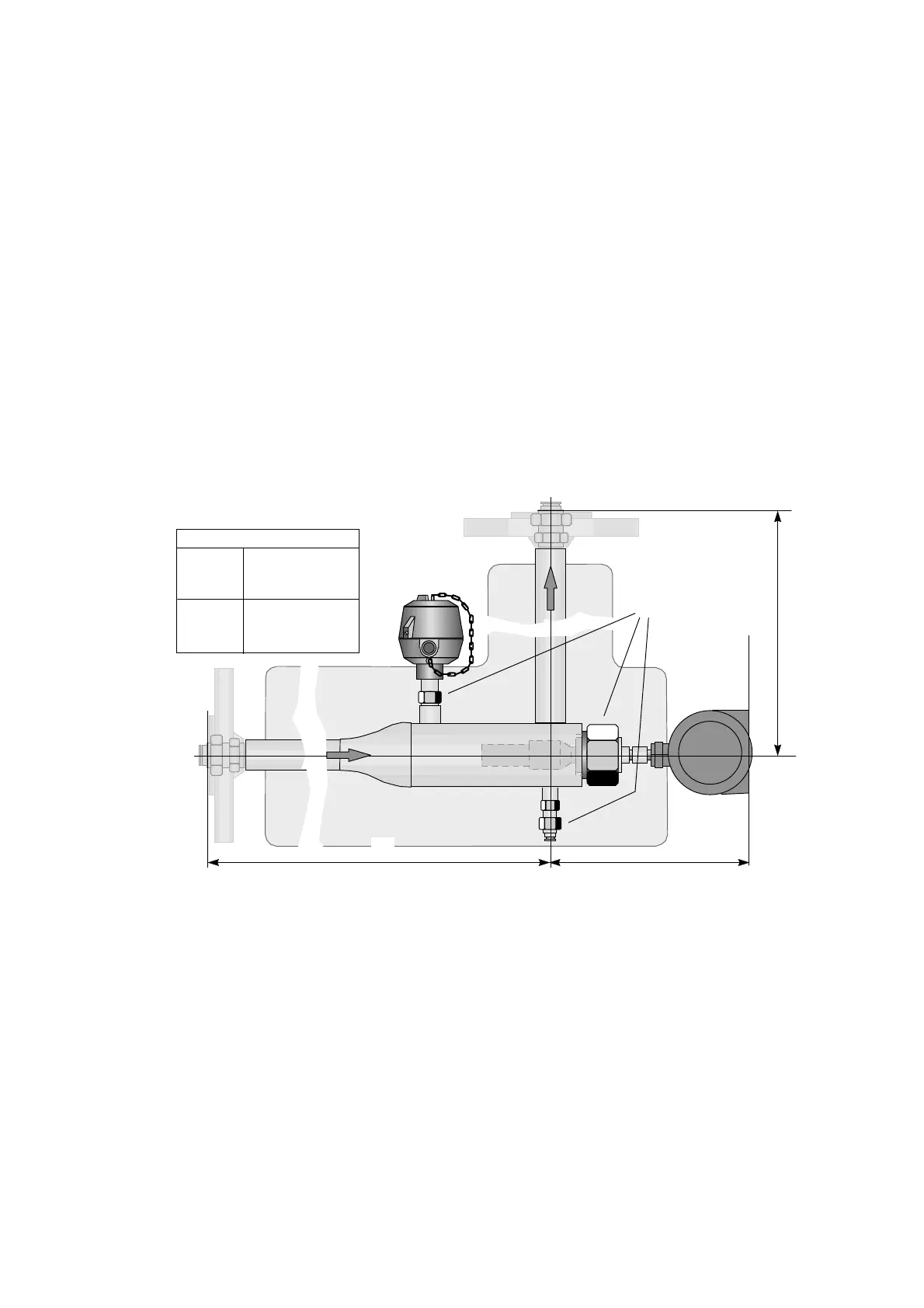

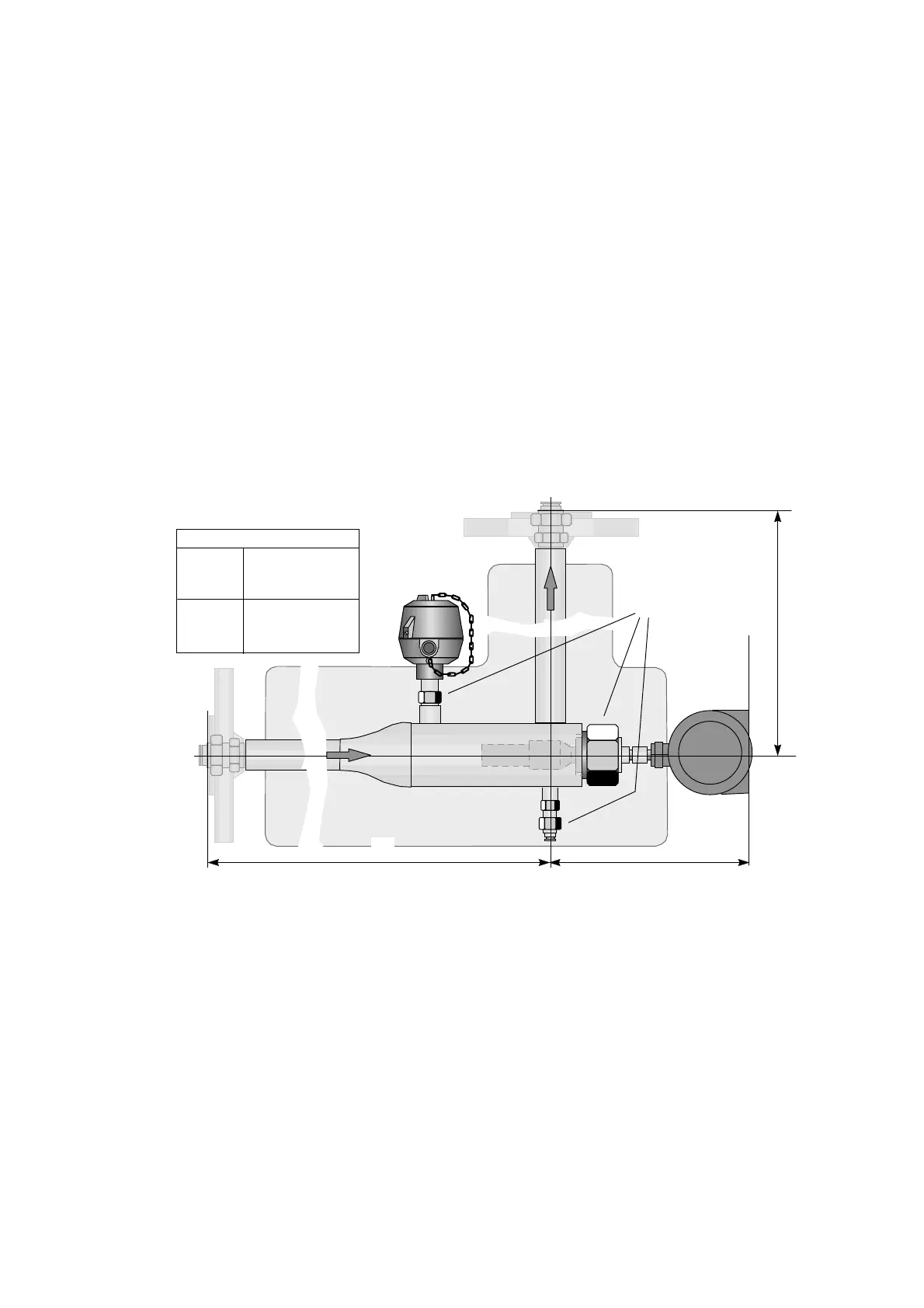

The diagram below shows the dimensions of this type of standard installation.

A

B

Drain: ½”

1½”

¾”

Swagelok fittings

Flow in

Flow out

Note: Datum lines must be preserved when

fitting flanges to weld-prepared tubes.

238mm (1” tubes) or

246mm (2” tubes)

Dims in mm. AB

1” Flange 480±3 335±3

1” Compr. 477±2 332±2

1” Weld 416±3 271±2

2” Flange 483±2 345±2

2” Compr. 522±2 384±2

2” Weld 409±2 271±2

1" Flow-through chamber

For optimum results the fluid flowing through the chamber should be homogeneous (plug

flow). This can be achieved by installing a static mixer immediately before the chamber.

Contact Solartron for advice about using flow-through chambers in hygienic applications.

Loading...

Loading...