7828 Density Transmitter Technical Manual Mechanical Installation

78285000_AB 2-11

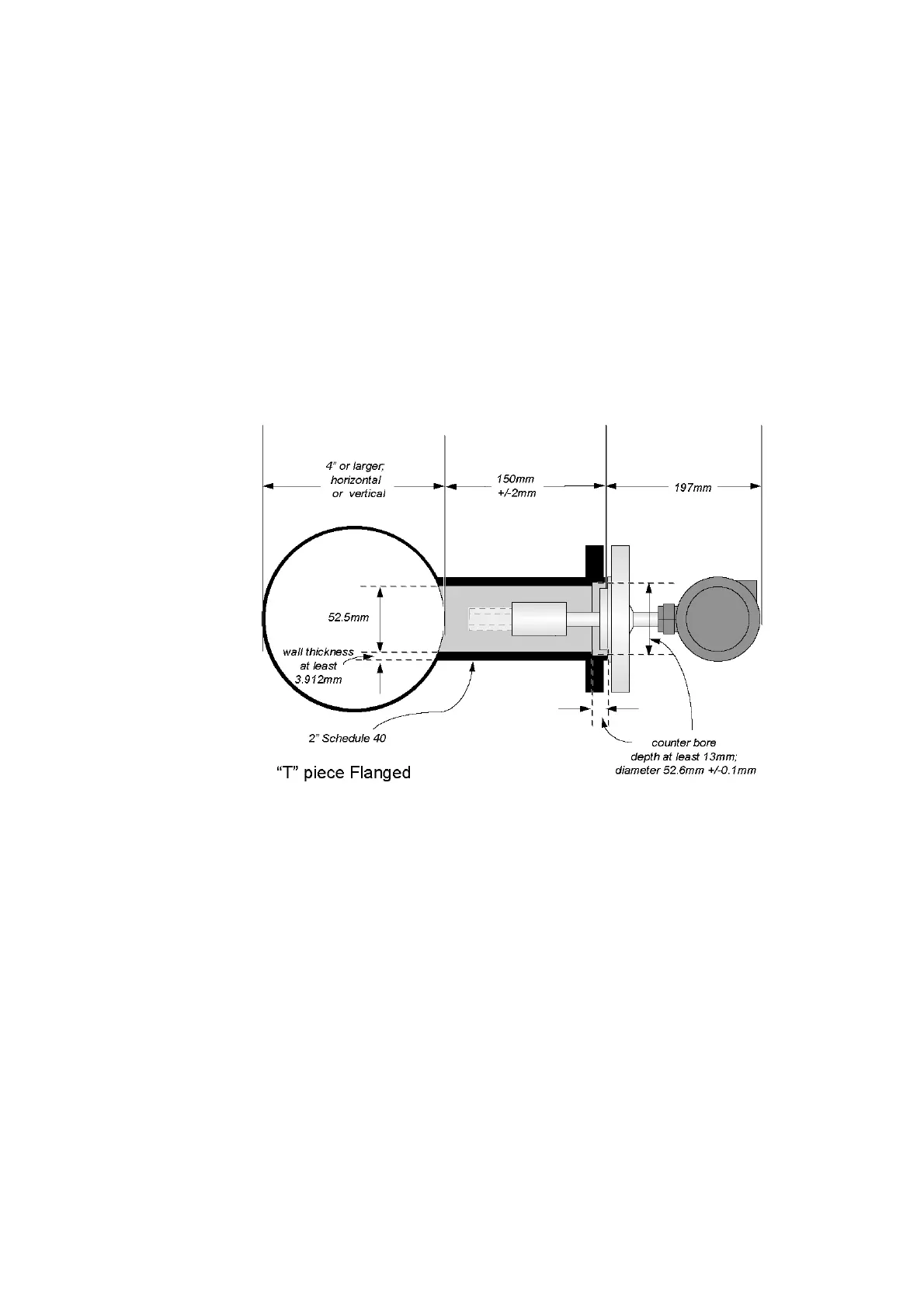

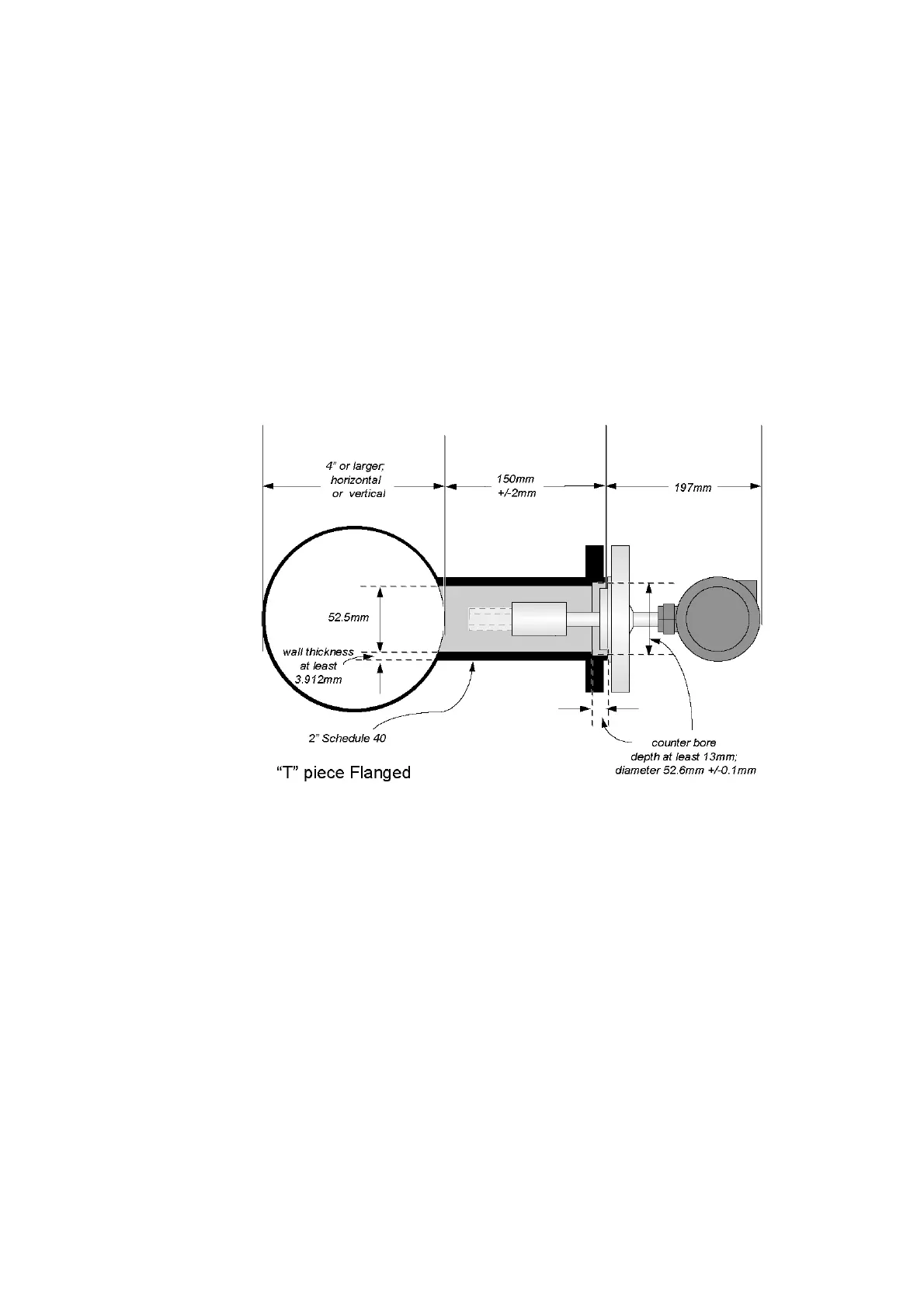

2.3.4 T-PIECE INSTALLATION

Conditions:

Flow: 0.5 to 3.0m/s (at the main pipe wall)

Viscosity: Up to 100cP, or 250cP under some conditions (See section 2.2.2)

Temperature: -50°C to 200°C

The thermal mass of the flanges may affect the response time of the transducer to

temperature changes.

Flow velocity at the pipe wall and fluid viscosity must be within the limits shown to ensure

that the fluid within the pocket is constantly refreshed. This installation will not respond as

rapidly as the free-stream installation to step changes in viscosity.

The view shown is schematic to show the dimensions of the side pocket, which is

fabricated by the end user.

The pocket geometry must be consistent with 2” schedule 40 tube in both internal

diameter and minimum wall thickness, i.e.:

internal diameter: 52.5mm

minimum wall thickness: 3.192mm

Alternatively, schedule 80 or 160 tube may be used, but this affects the calibration, and

must therefore be specified when ordering the sensor.

Counter bore the pocket to a minimum depth of 13mm and diameter 52.6 ±0.1mm to

locate the 7828 centrally.

Weld neck or slip-on flanges may be used, according to the flange rating selected.

However, for higher rated flanges, only slip-on flanges may give the necessary

clearances.

For normal flow conditions (up to 3m/s at the pipewall), the tines should be retracted

25mm from the main pipe wall. For higher flow rates, increase this by 10mm for every

1m/s increase in main flow rate.

Loading...

Loading...