Page 29

7 Periodic Maintenance

7.1 Maintenance Schedule

Sonic 150 series blowers are designed for 24 hour / 365 day operation with periodic

service and / or replacement of the belts and filters.

The following inspection and service intervals are listed as hours of operation or elapsed

time from blower installation, whichever comes first. It is always preferable to perform

maintenance earlier than recommended, especially in hot, cold, wet, dirty, or otherwise

hostile environments.

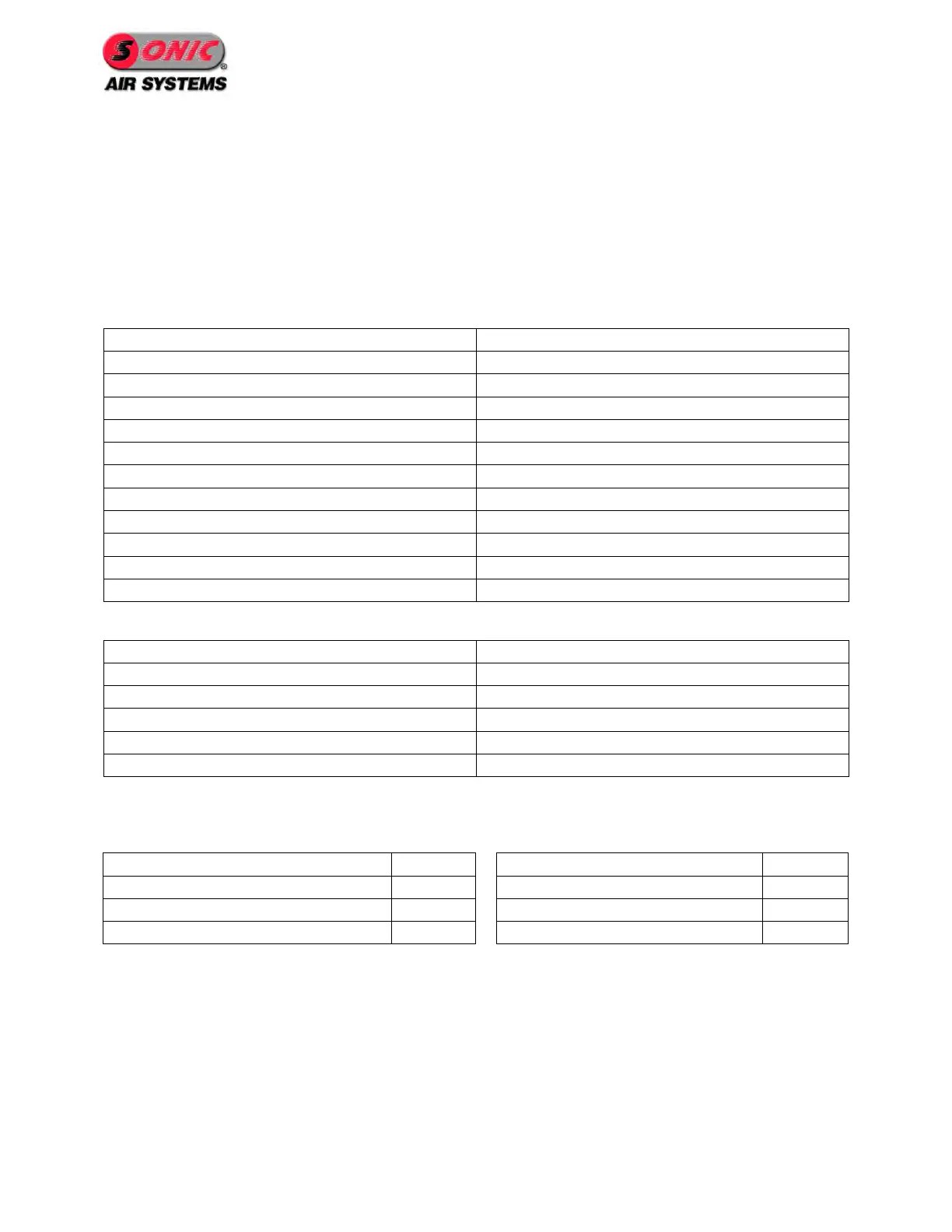

Inspect filter / Replace or Clean filter element

Inspect motor and grease bearings

Bearing cartridge bearings

Sealed – No Service Required

Replace bearing cartridge

Inspect blower and motor pulley

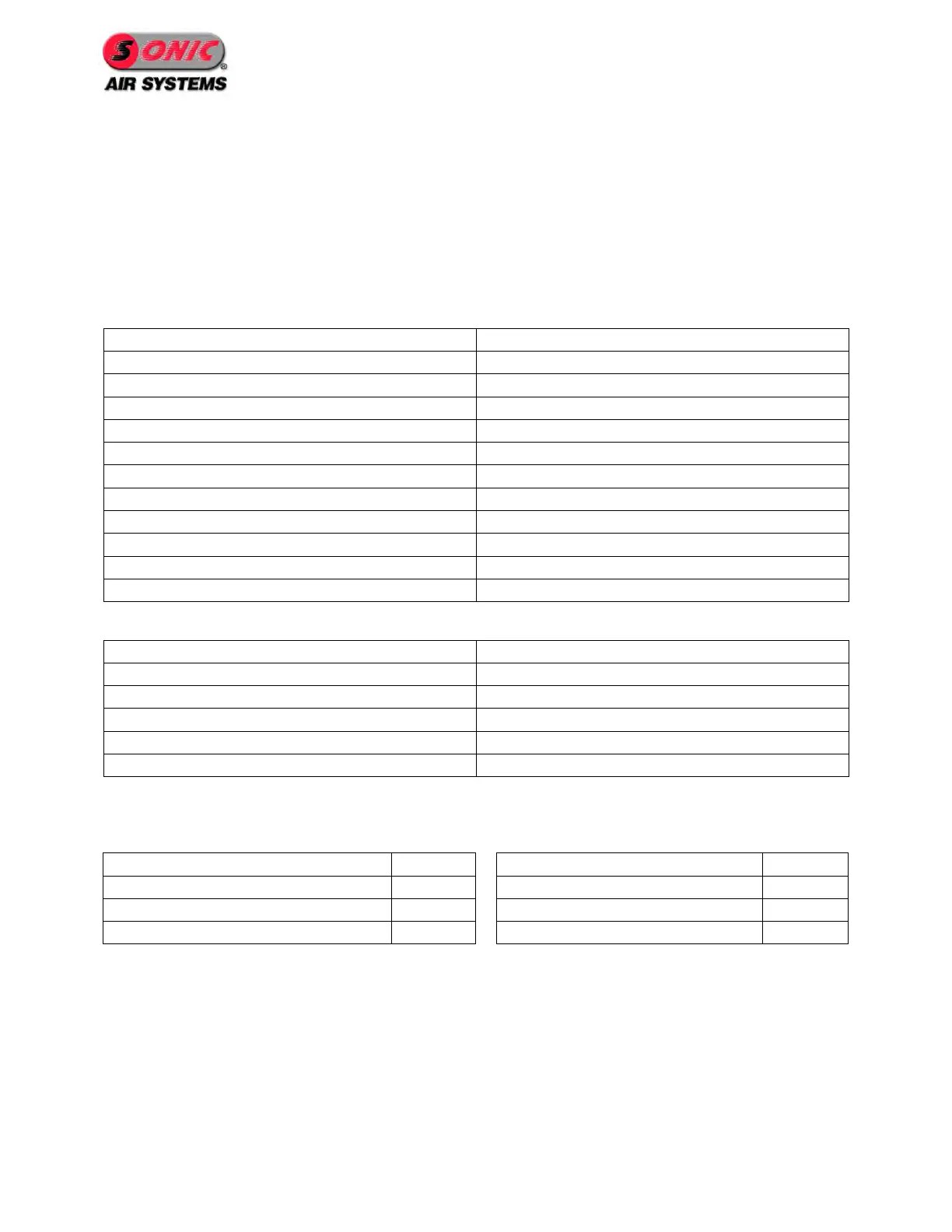

7.2 Torque Specifications

7.3 Belt Replacement Procedure

7.3.1 Tools Required

¾ inch deep socket (optional)

#3 Drive Extension (optional)

7.3.2 Belt Replacement Procedure

1. Remove the belt guard using the 1/2 inch socket. (See Figure 36)

2. Using the 9/16 inch box-end wrench, rotate the belt tensioner arm counter

clockwise (CCW) and remove the belt. (See Figure 37)

3. Clean any belt debris or dust from blower and pulleys. Do not use any abrasive

materials on the pulley grooves as this will damage the grooves and cause

subsequent belt failures.

Loading...

Loading...