Page 3

joining the blower and motor has a belt guard completely enclosing the drive assembly

and completing this integral design.

With air / gas delivery up to 1,200 CFM (566 lps), this unit is well suited for any

application with pressures to 4.5 psi (0.31 bar). As a result of the high-speed operation,

the total envelope of the blower / motor assembly is one of the most compact and

lightweight within its performance range.

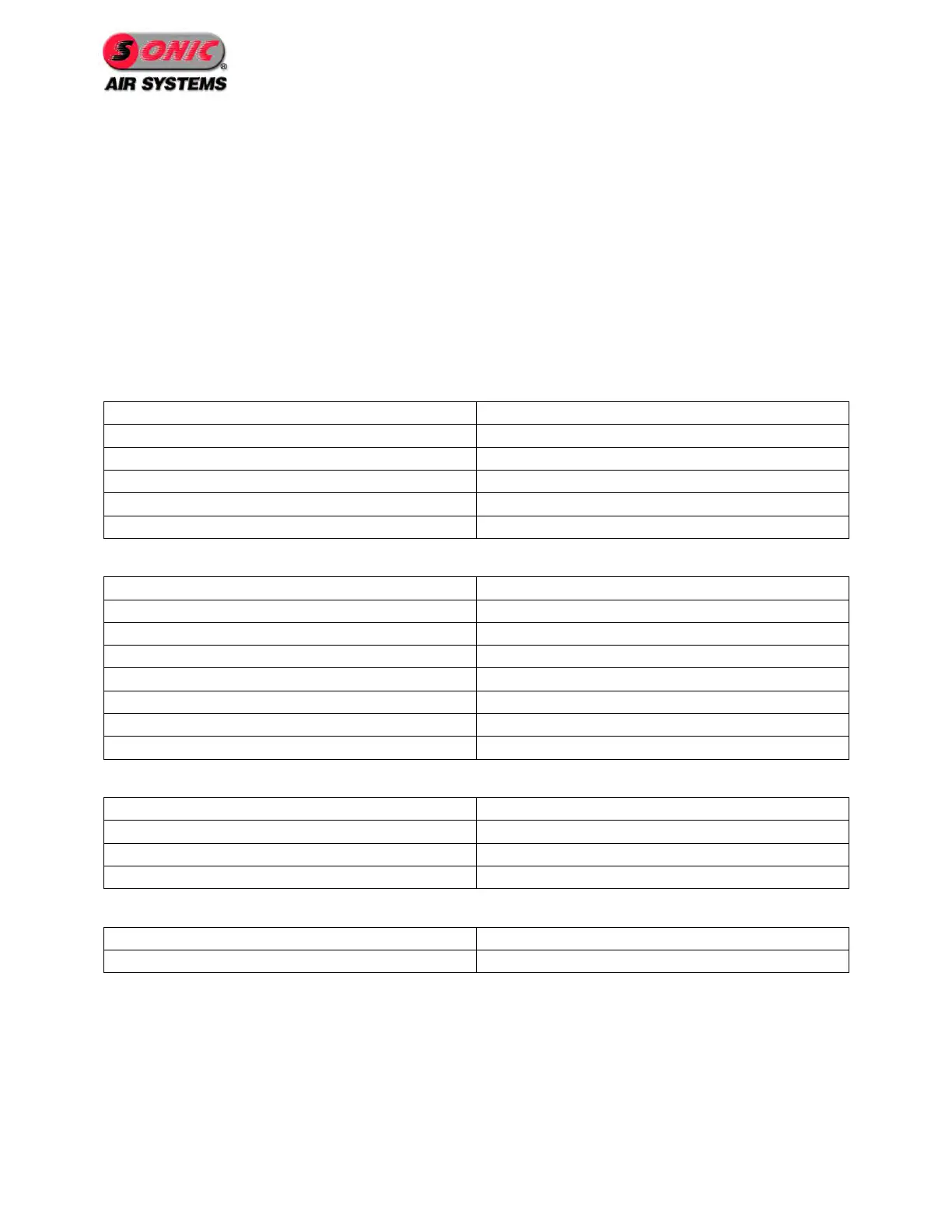

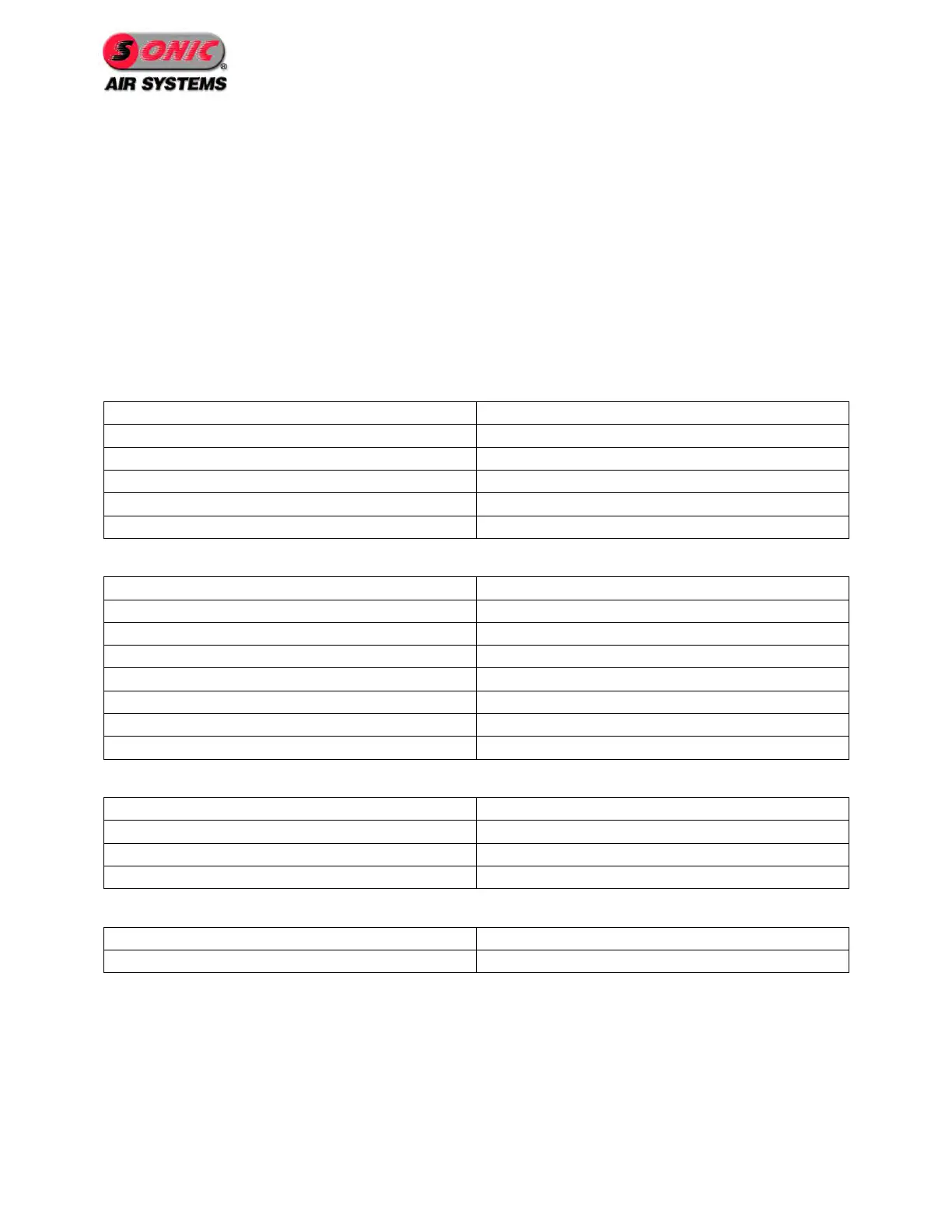

1.4 Typical Applications

The following is a list of typical applications for using a Sonic 150 centrifugal blower

assembly. This is only a partial list of the possible uses for supplying low cost, clean air

to a particular application. Please consult a Sonic Application engineer to design a

system to meet any request.

Hydrocarbon vapor recovery

Environmental test chambers

Oil spill containment booms

Special applications and options are available for the Sonic 150 blower unit:

Corrosion resistant electroplating

316 Stainless Steel Material Option

Welded inlet and outlet flanges

In-Line filters and water separators

Water cooling of the bearing housing

Operation to 400°F inlet air temperature

Thermocouple monitoring of bearings

Premium Efficiency (PE) motors

Sonic also provides a full line of air / gas handling accessories:

Air blowers from 3 to 50 horsepower

HEPA filters to 1,000 CFM

High efficiency aluminum air knives

High efficiency stainless steel air knives

Sonic services four main industries:

Metal and Sheet Fabricators

Please contact a local Sonic representative or a Sonic application engineer to discuss any special

considerations or applications.

Loading...

Loading...