8999151EN: v1 11/03/2021

73

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

treated alloy steel. Substitute blades may not meet specifications and may fail in a hazardous manner that could

cause injury.

Spearhead declines all responsibility for damage and/or injury caused by use of anything other than the blade

carriers/blades which are supplied with the machine as new or sold as a spare part replacement sold by a

genuine Spearhead parts dealer on Multicut rotary machines.

See Section 7 for guidance on spare parts. The machine serial number will be required to be quoted. Serial plate

location guidance can be found in Figure 1.4.

5.4.3 Blade Sharpening & Straightening

Spearhead does not recommend sharpening worn blades. It is important that all the blades on a rotor, are

of the same weight and length and are all present to ensure the rotor remains balanced. By sharpening

blades there is a chance of them overheating, which will affect the hardness of the blades; compromising safety

to the operator, machine and bystanders.

DANGER! Never attempt to straighten or weld on blades. This is likely to cause potential cracks and

other damage to the blade. Subsequent failure and possible serious injury will occur from thrown blades.

NOTE: Spearhead declines all responsibility for damage and/or injury caused by sharpening/straightening

and/or modifying blades on any Multicut machines. If you are unsure of the condition of your blades, and feel

you need additional assistance, please contact your local Spearhead dealer, qualified service centre or

Spearhead.

5.4.4 Blade Removal & Replacement

Equipment Required

• Torque wrench (see required settings in Torque Settings section)

• 36mm hex sockets/spanner

• 36mm hex spanner

WARNING! It is mandatory to switch the combustion engine off and disengage PTO and ensure that

the tractor and machine is stopped, the ignition key is removed from the dashboard and the parking

brake is engaged before leaving the driver’s seat and proceeding to adjust the levelling of the machine.

Before proceeding to remove and replace the blades of the machine, correctly assess the condition of the blades

by reading the guidance given in Section 5.4.2.

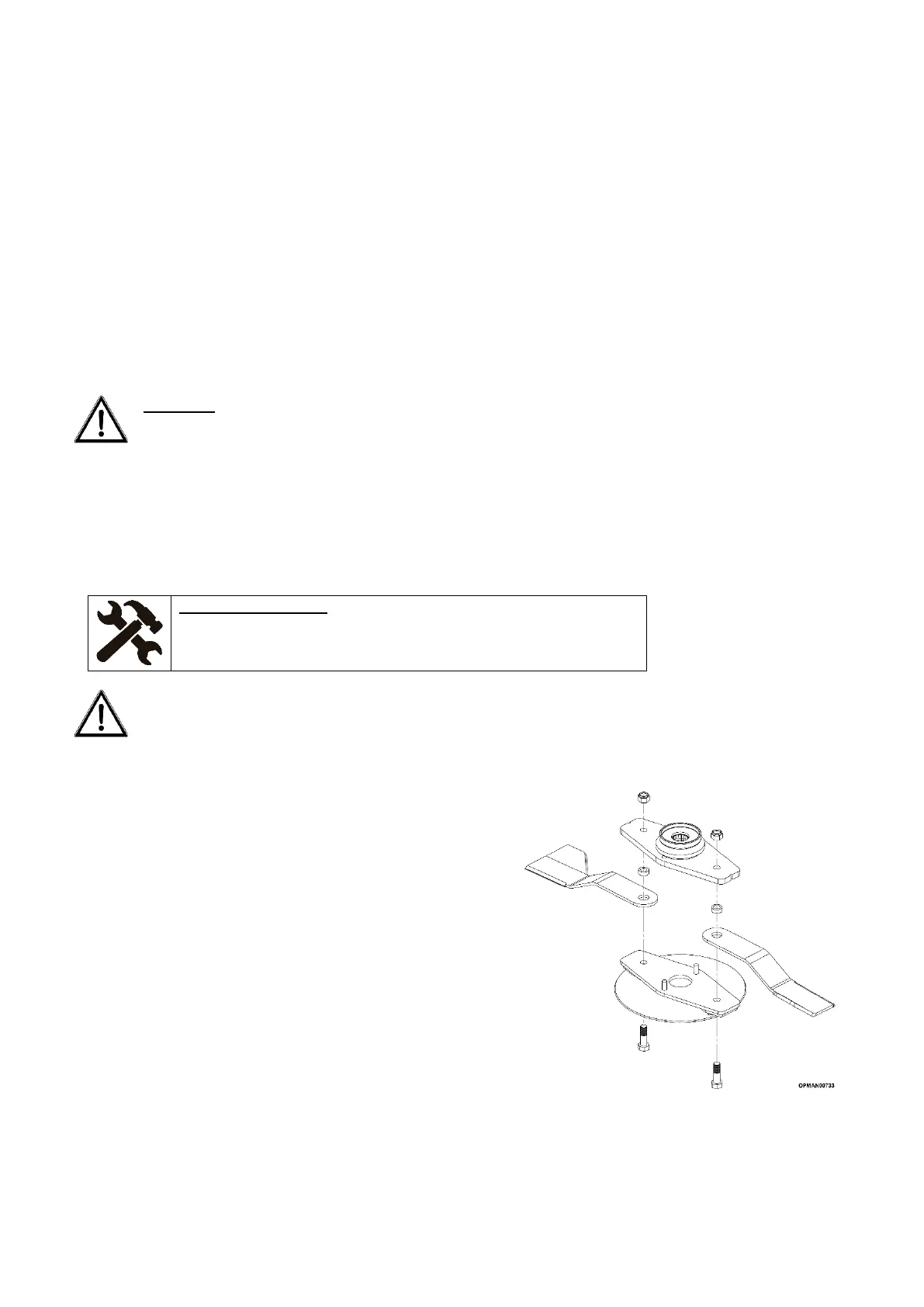

If blade replacement is required, in order to not need to remove

the lower blade carrier of the rotor, remove and replace each of

the blades of the machine one at a time. When replacing rotor

assemblies with new blades, due to their free swinging ability, it

is important to fit new hardened bushes into the blades at

the same time. This can ensure the rotor is remained

balanced. Blade bolts and nuts should be replaced

whenever blades and bushes are removed; whether the

blades are requiring replacement or not.

Multicut blades are handed. It is important to make a note of

the direction of the particular rotor in question and to ensure

that the correct blade is fitted to the rotor and correctly

orientated. For guidance on the rotation directions of each of

the rotors, see Section 1.4.

Figure 5.20 – Multicut Blade

Carrier Assembly

(standard shown)

Loading...

Loading...