8999151EN: v1 11/03/2021

84

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

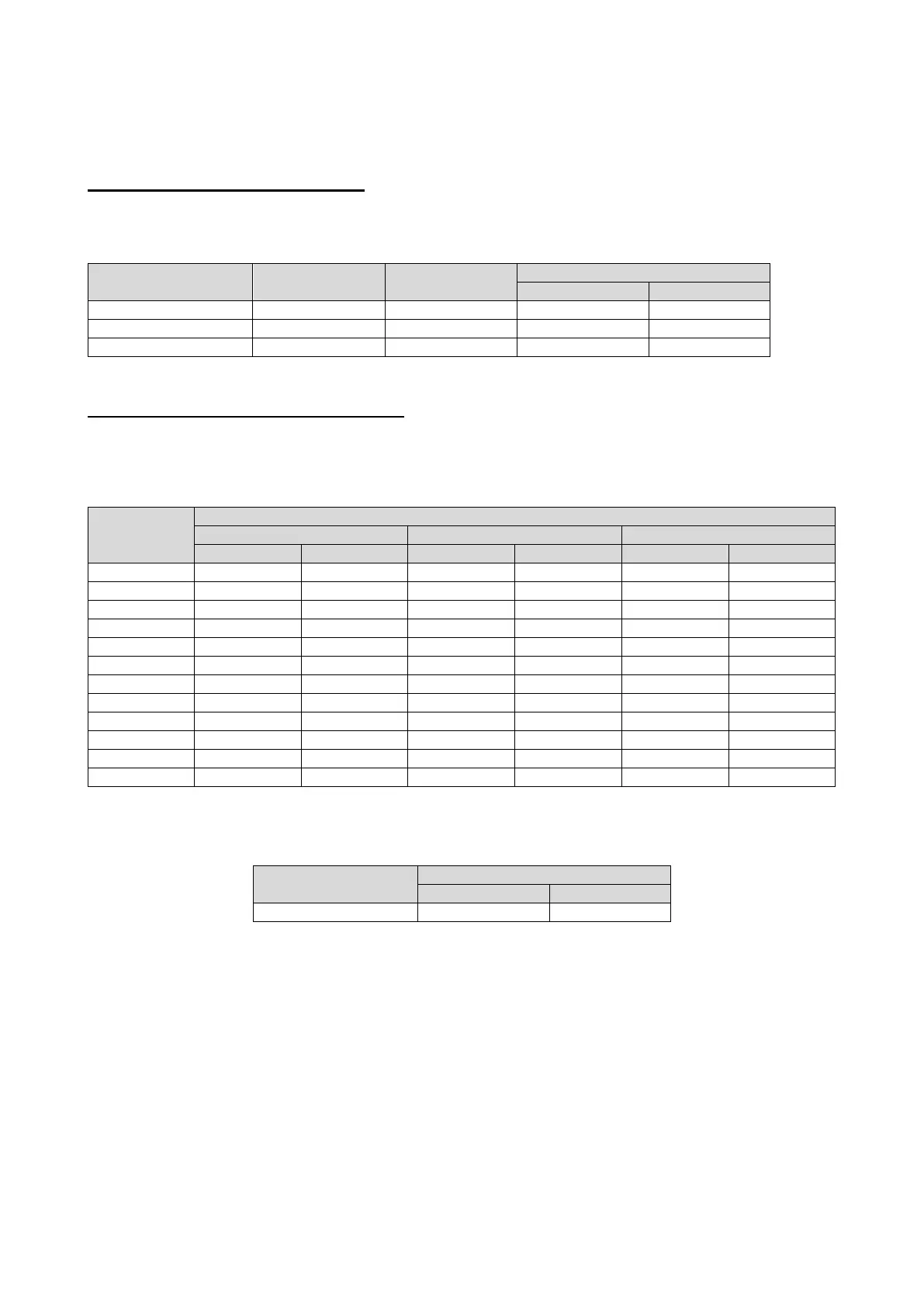

5.7 Torque Settings

5.7.1 Nuts & Bolts

Specific Fastener Requirements

On Multicut machines, there are some special fasteners/components which require specific torque settings to

ensure they operate safely.

Table 5.11 – Multicut Specific Fastener Torque Settings

Non-specific Fastener Requirements

The below tables give reference to the maximum recommended tightening torques for standard, zinc plated

finished bolts on Spearhead machines. These settings can be applied to hex, socket countersunk and

socket button screws.

Table 5.12 – Standard Fastener Torque Settings

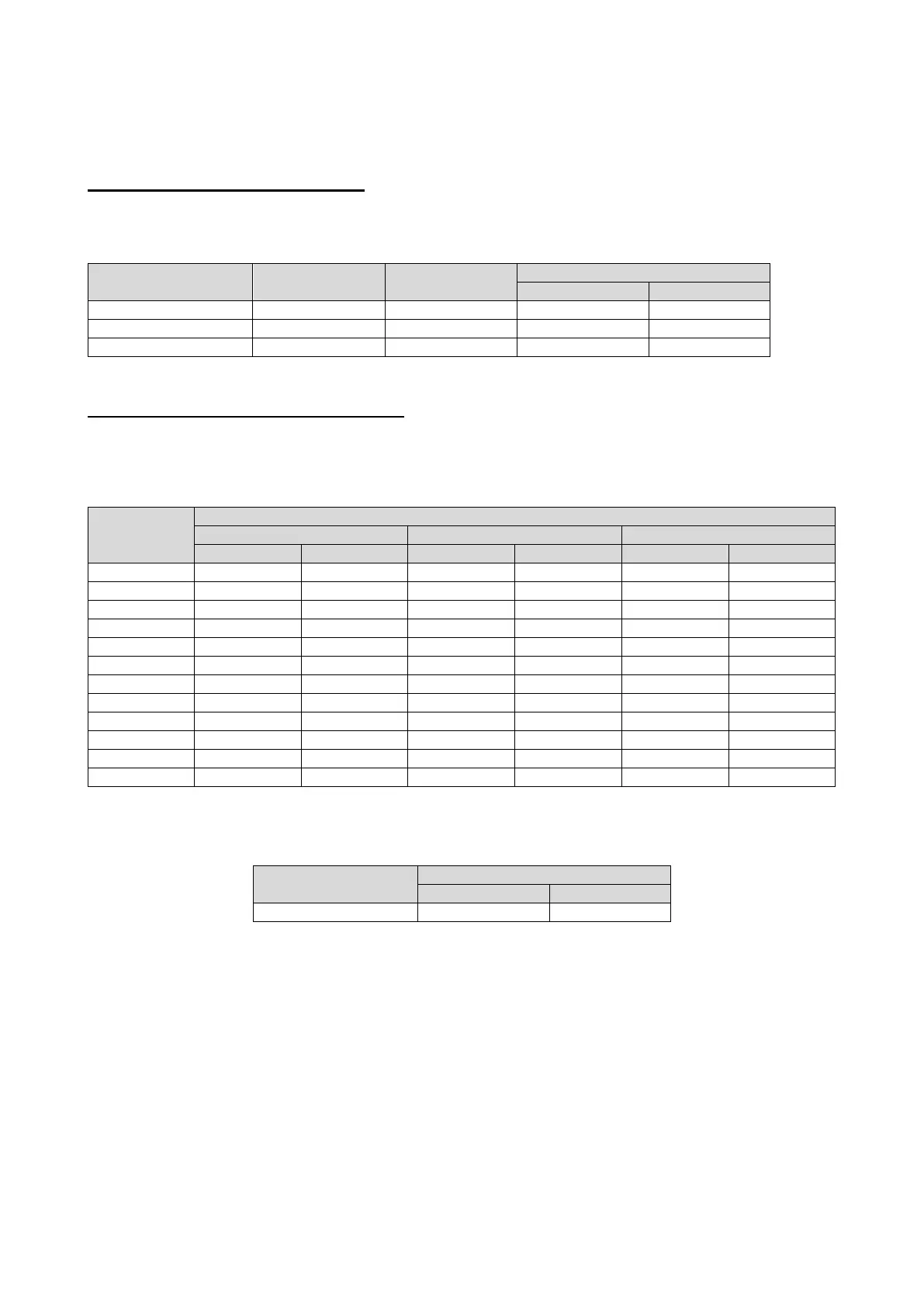

5.7.2 Other Items

Table 5.13 – Multicut Specific Fastener Torque Settings

Loading...

Loading...