8999151EN: v1 11/03/2021

77

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

5.4.7 Anti-scalp Dish, Blade & Blade Carrier Removal & Replacement

IMPORTANT: Throughout this section be aware of the blade carrier and blades rotating. Before proceeding to

carry out any of the operations stated in this section; see Section 5.4.2 with regards to handling blade carrier

assemblies safely.

Throughout this section, the process is shown on a right-hand rotor. For complete clarity the exact same process

is applicable to the other left-hand rotor.

Anti-scalp Dish, Blade & Blade Carrier Removal

Equipment Required

• Torque wrench (see required settings in Torque Settings section)

• 36mm hex sockets/spanner

• 36mm hex spanner

• 55mm hex spanner

• Needle nose pliers

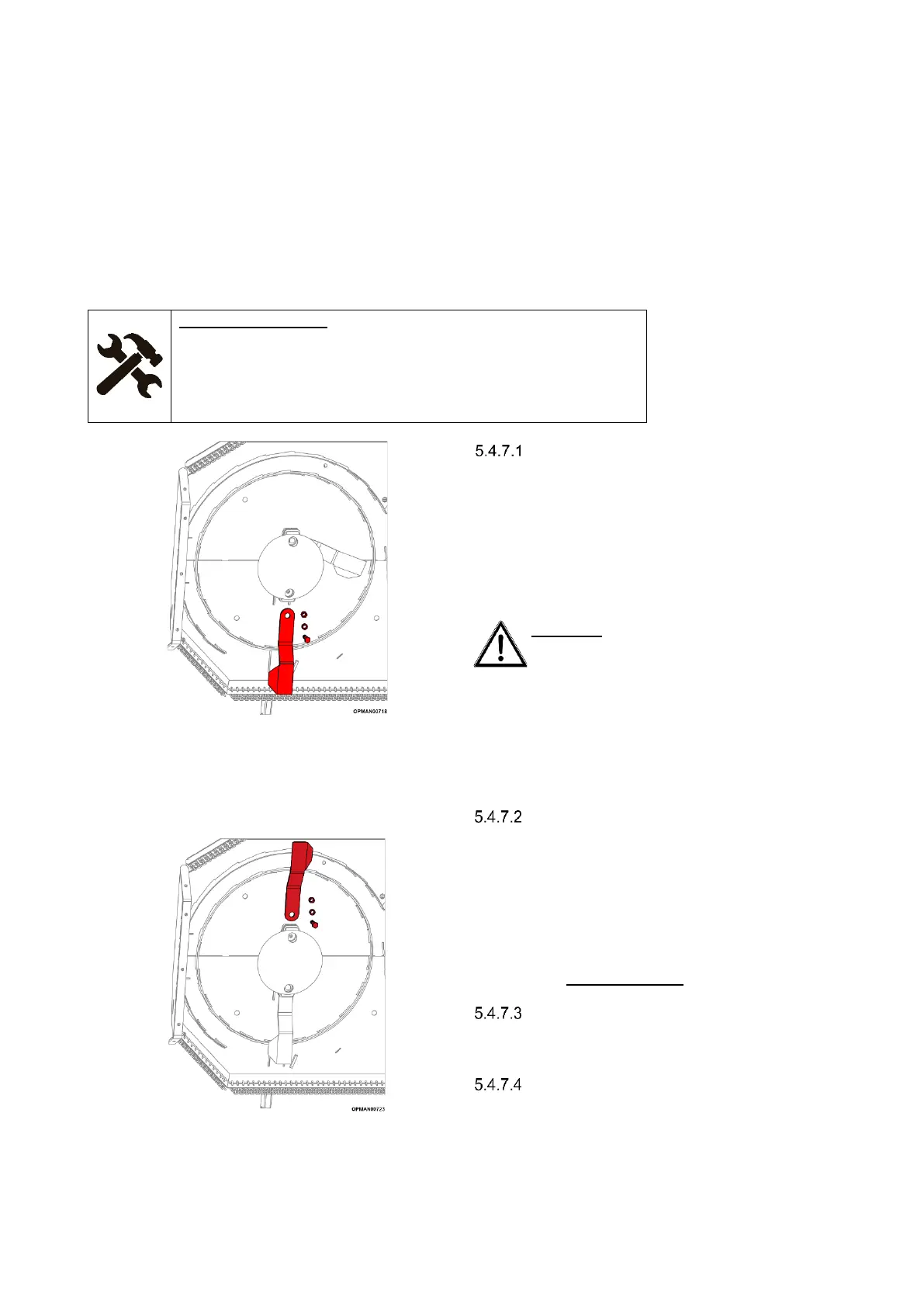

Before proceeding to carry out any work

ensure that the blades and blade carrier

are in their “dropped” and in a stationary

position on both rotors.

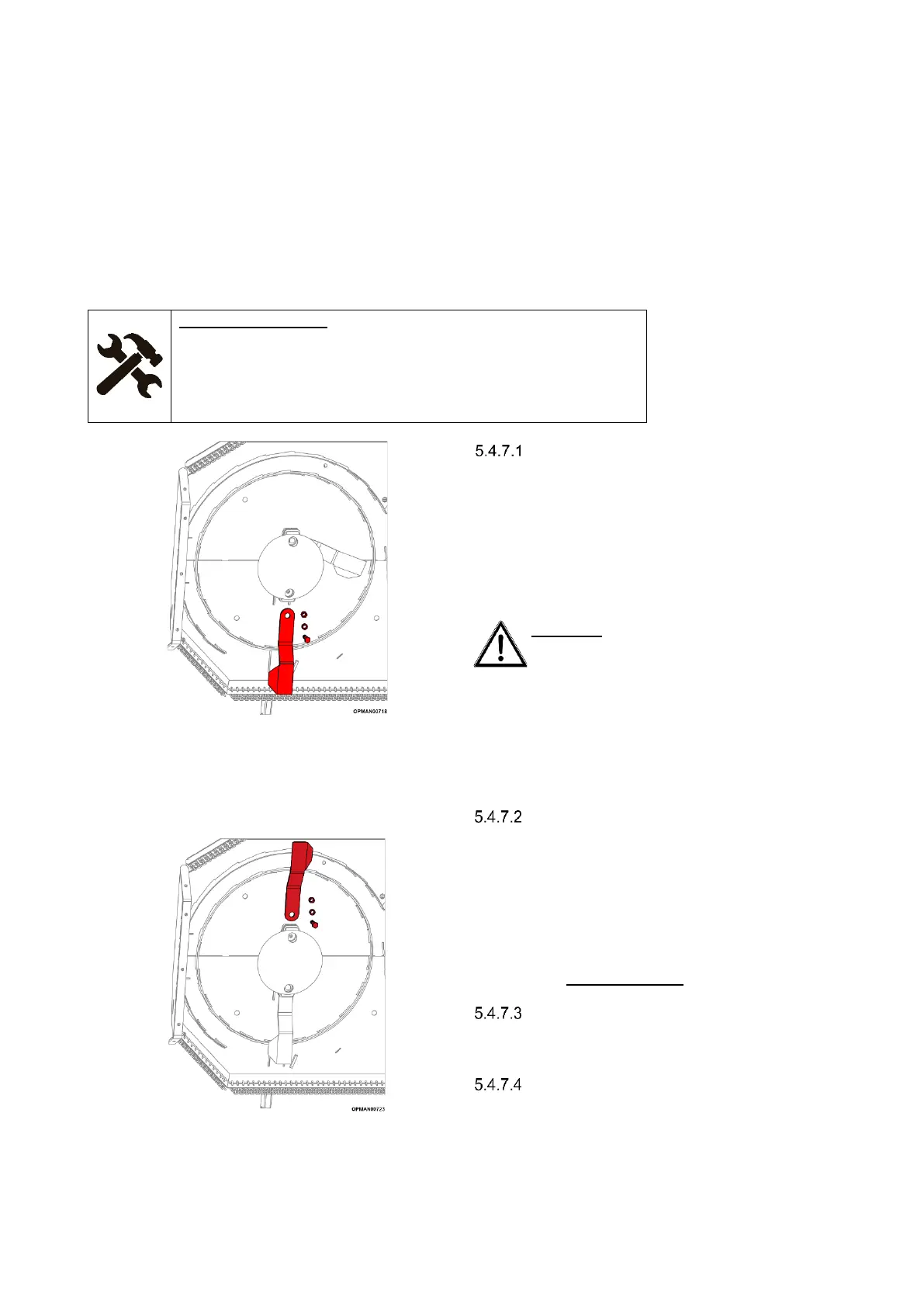

Ensuring that you’re wearing suitable

gloves, proceed to loosen the fasteners on

the first blade and carefully remove the

bolt, bush, nut and blade.

DANGER! When carrying out maintenance

work on or near the blade carrier, be careful

of free-swinging blades over-centering and

falling. It is recommended that Personal

Protection Equipment (PPE) is worn.

If an anti-scalp dish replacement is required proceed

to 5.4.7.5.

If the maintenance required is simply a

blade replacement and the blade carrier is

still in good condition, proceed to install the

new blade, with an accompanying new

bolt, bush and nut.

It is of upmost importance that new

fasteners and bushes are used on the

reassembly. Blade fasteners and bushes

are single use items.

Torque the new fasteners to the

recommended torque as stated in Section

?.?

Repeat processes 5.4.7.1 to 5.4.7.3 in the

same fashion on the second blade.

It is important that if a new blade is fitted

that the second “opposite” blade is

replaced also with a new item. This is to

ensure that the rotor when in operation

does not experience issues with vibration.

Loading...

Loading...