8999151EN: v1 11/03/2021

82

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

IMPORTANT: Do not use any other wheel/tyre than those recommended/supplied by Spearhead.

Spearhead declines all responsibility for damage and/or injury caused by use of anything other than the

wheels/tyres which are supplied with the machine as new or sold as a spare part replacement sold by a

Spearhead dealer on Multicut rotary machines. If you are unsure of the correct wheel/tyre for the machine,

or need additional assistance, please contact your local Spearhead dealer, qualified service centre or

Spearhead.

5.5.1 Tyre Pressures

Equipment Required

• Air supply with Schrader valve

Tyre pressures should be checked weekly and when they’re cold to ensure their longevity and wellbeing as well

as the safety and stability of the machine in use and to ensure level cutting when the machine is in work.

Table 5.10 – Multicut Tyre Pressures

5.5.2 Hub Greasing

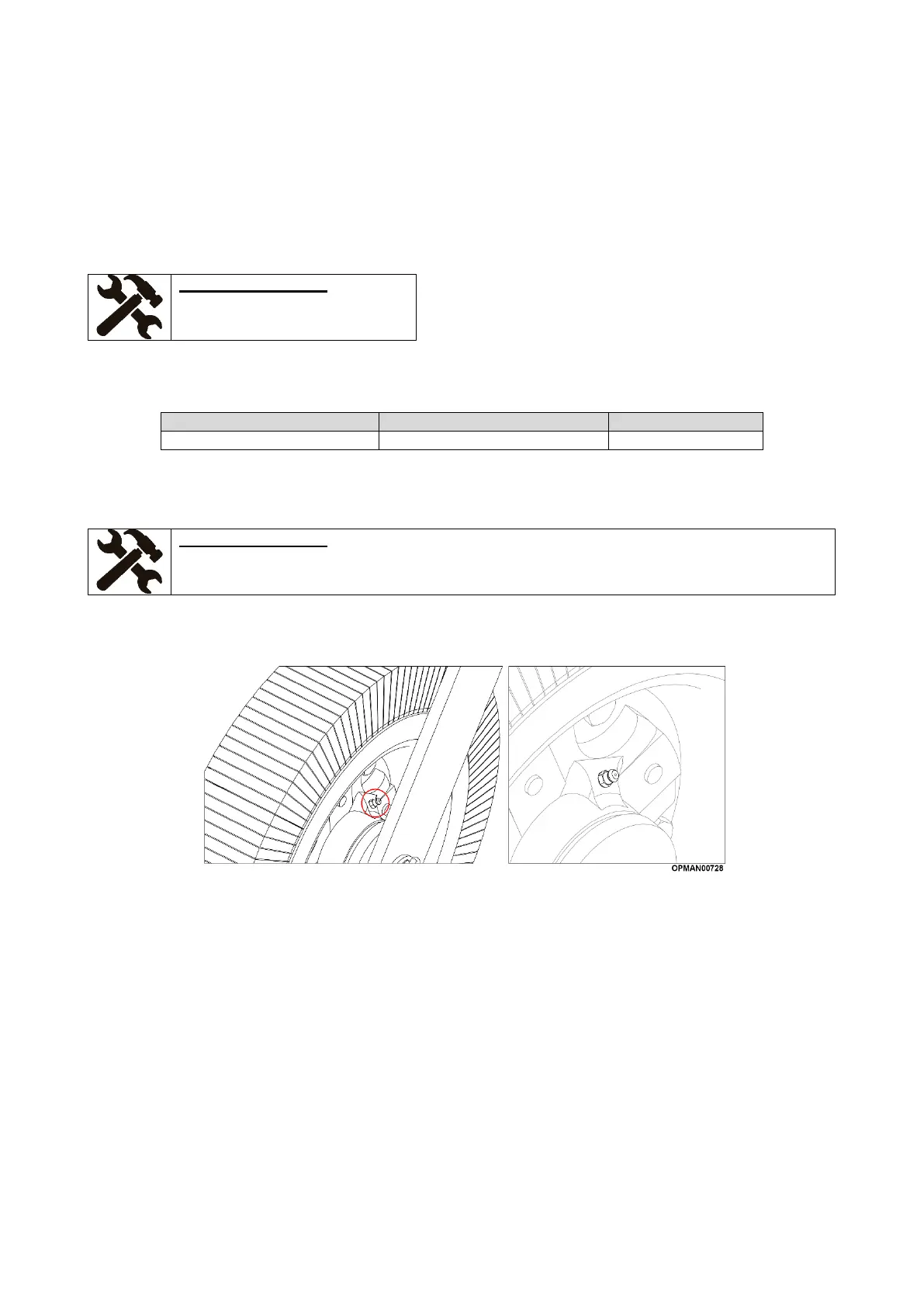

Equipment Required

• Manually operated grease gun supplying NLGI #2 Molybdenum Disulphide Grease to M6/M8

grease nipples

The Multicut 300 laminated wheel hubs feature grease nipples which need to be greased at least once a week

(dependant on amount of machine use); see Figure 5.35.

Figure 5.35 – Multicut Laminated Wheel Hub Greasing Location

The Multicut 300 standard wheel hubs feature a sealed bearing. This requires no weekly maintenance, but

however still requires a regular inspection of the condition of the bearing to ensure no rumble or excessive play

is apparent.

Loading...

Loading...