8999151EN: v1 11/03/2021

74

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

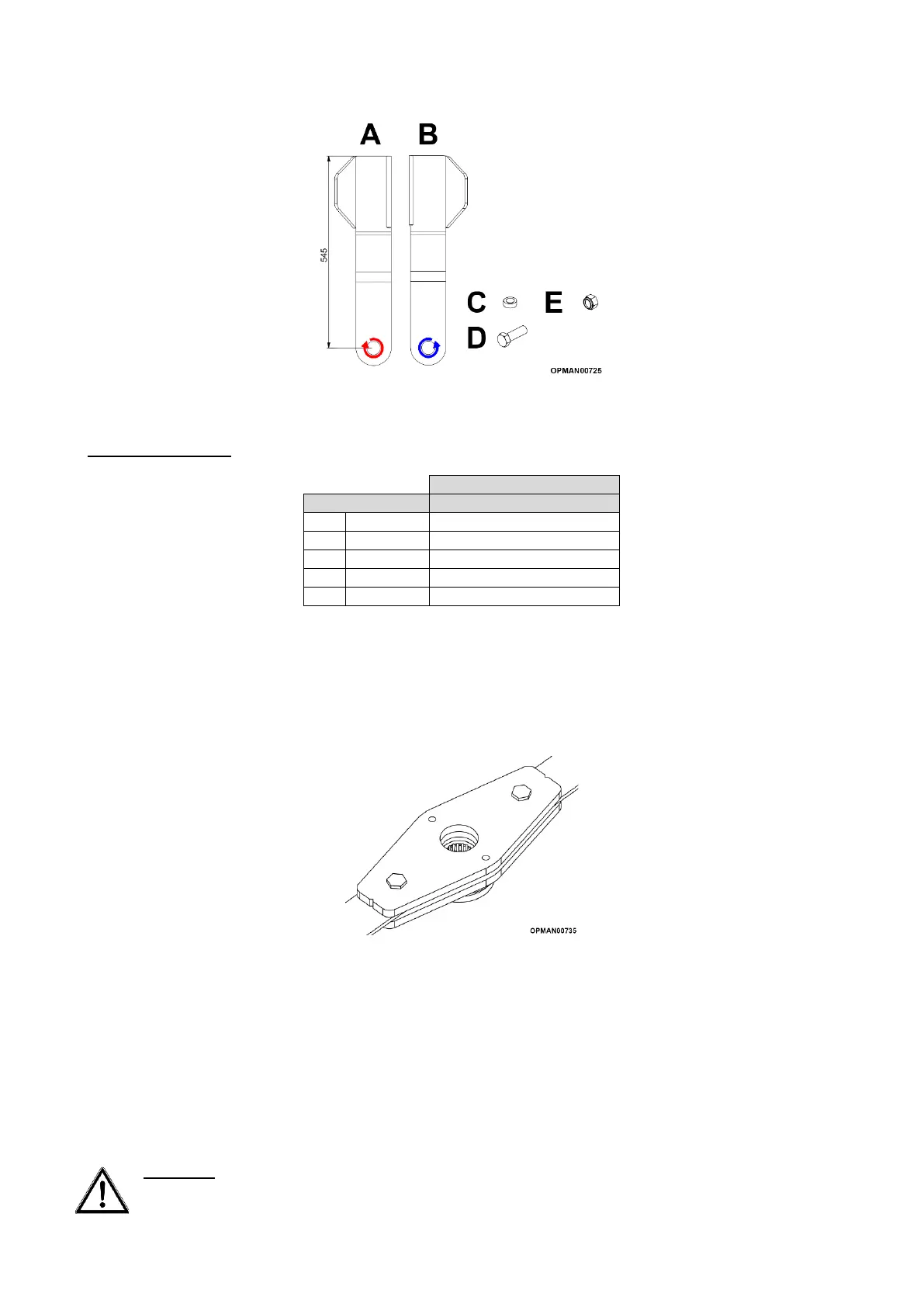

Figure 5.21 shows the left-hand and right-hand blades definitions and the direction in which they’re meant to cut.

Table 5.9

5.4.5 Blade Bolt Inspection

Blade bolts are prone to getting damaged when coming in contact with foreign or solid objects which can

seriously compromise the wellbeing of machine, the operator and bystanders. Neglecting damaged blade bolts

can cause serious injury or death.

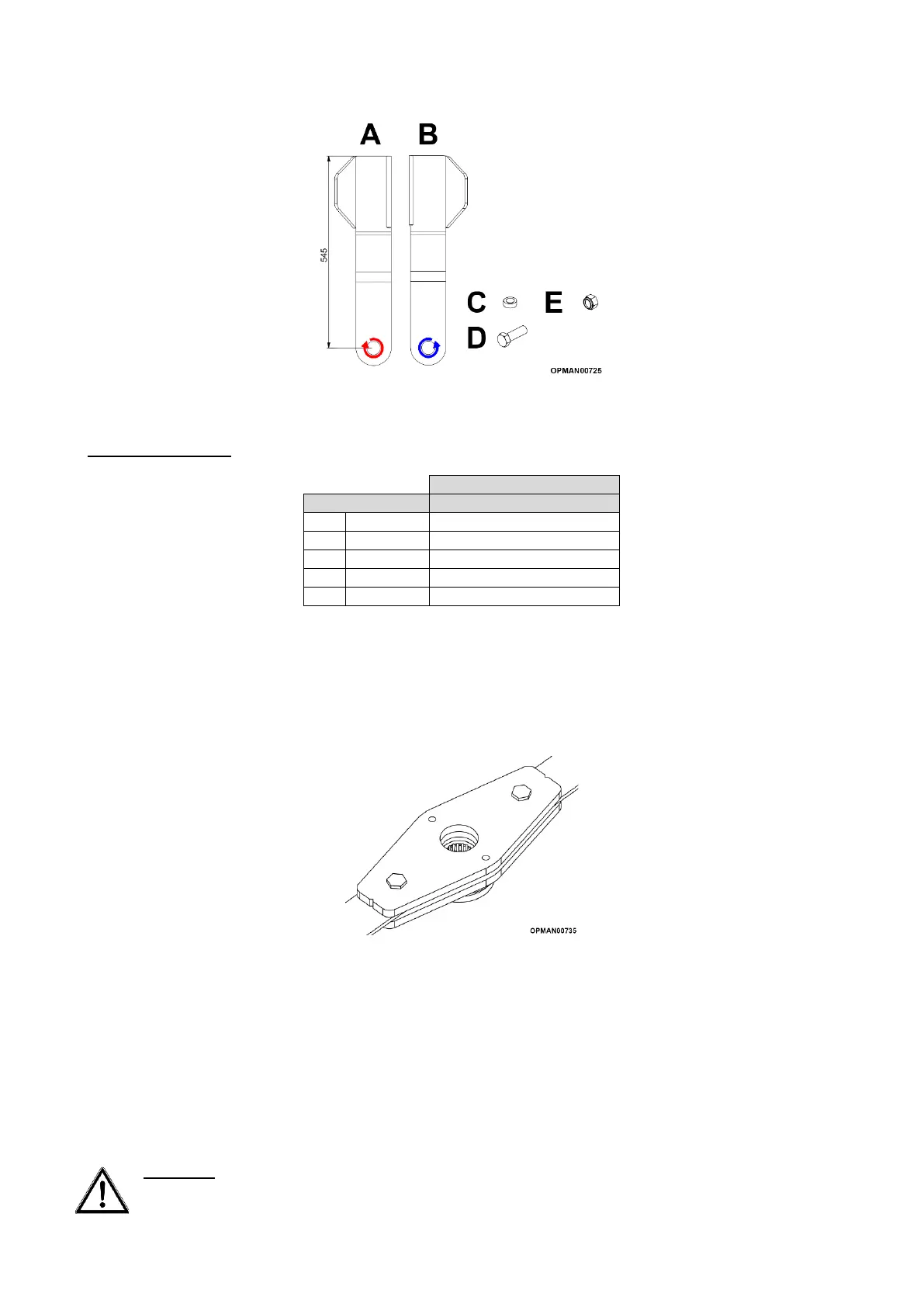

Figure 5.22

Heavy-duty Blade Carrier

The heavy duty blade carrier, an option available on the Multicut 300 (see Figure 5.22) is particularly prone to

blade bolt wear due to it exposed design. The standard blade carrier, which features an anti-scalp dish and the

bolts are more recessed are less prone to wear and damage.

Inspect the heads of blade bolts daily for:

• Visible cracks

• Wear on the recessed area of the head of the bolt

• Gouges and chipped areas

• DANGER! Failure to inspect daily and replace worn or damaged blade bolts may lead to catastrophic

failure of the blades and ejection of the broken part which may cause serious bodily injury or death.

Loading...

Loading...