8999151EN: v1 11/03/2021

76

Original instructions (ENGLISH)

Website: www.spearheadmachinery.com

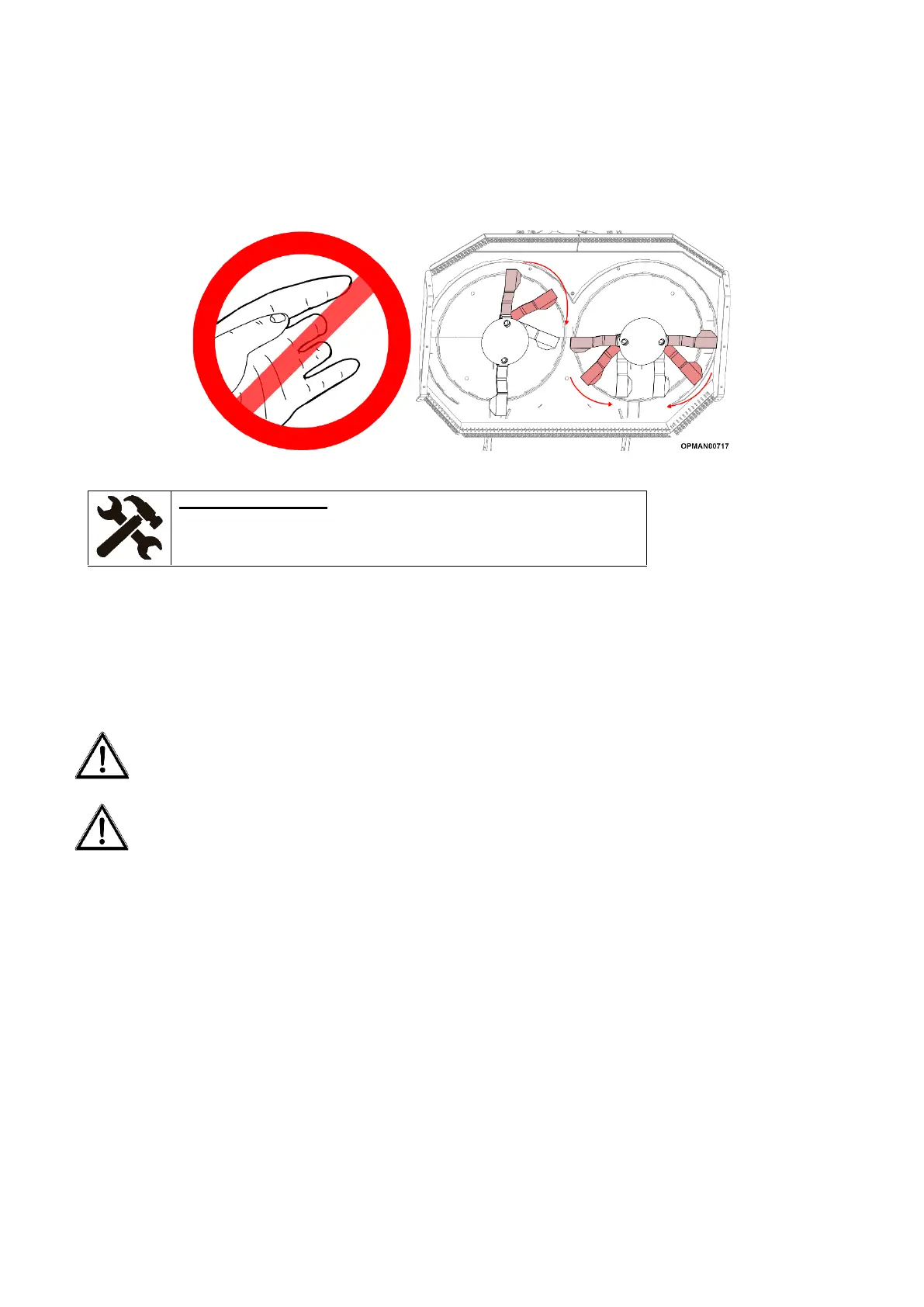

When servicing or inspecting any anti-scalp dish lower blade carrier of any type when the machine is lifted, it is

important to ensure that the blade carrier and blade assembly is moved into its “dropped” position to ensure

nothing suddenly falls due to the force of gravity. When the Multicut machine is lifted this should automatically

happen, but for any reason if it hasn’t, sufficiently hold the blades towards the outside and gradually rotate and

pre-place them into their dropped position; as shown in Figure 5.24. This will ensure that personnel do not get hit

by falling blades or pinched/trapped between the blade and the carrier.

Figure 5.24 – Beware Of Falling Blades

Carefully wiggle the blade carrier assemblies and check each of the rotors for looseness of fasteners. Retighten

any loose parts to the correct torque figure. See Section 5.7 for torque settings. Blade carrier fasteners should be

checked after the first hour and then every 8 hours thereafter.

IMPORTANT: Operating with loose blade components will damage the blade carrier and blades. Whenever the

blades and blade carrier have been removed or replaced, the tightness of components should be checked

after the first hour and then every 8 hours thereafter.

WARNING! Inspect the area before mowing. Foreign objects should be removed from the site prior to

beginning work to prevent machine damage and/or operator, bystander or the environment. Any objects

that cannot be removed must be clearly marked and carefully avoided by the operator.

WARNING! Pay special attention when working with the machine and do not allow the machine to touch

fixed objects such as road drains, walls, shafts, curbs, guard rails, tracks etc. as these could break the

blades or blade carrier which could cause debris to be thrown at very high speed from the machine.

As a preventative measure and to reduce blade and blade carrier wear and potential detrimental damage,

inspect the destined working area of the machine to determine where foreign object hazards are. Remove these

hazards and if they aren’t easily removable, place visual markers where items are to ensure that the tractor and

machine do not come into contact with these hazards.

IMPORTANT: Always use genuine Spearhead parts when carrying out repairs and maintenance with thoughts

to longevity and reliability of the machine and personnel safety. Spearhead blade carriers are made of special

heat-treated alloy steel. Substitute blade carriers may not meet specifications and may fail in a hazardous

manner that could cause injury.

Spearhead declines all responsibility for damage and/or injury caused by use of anything other than the blade

carriers/blades which are supplied with the machine as new or sold as a spare part replacement sold by a

genuine Spearhead parts dealer on Multicut rotary machines.

See Section 7 for guidance on spare parts. The machine serial number will be required to be quoted. Serial plate

location can be found in Figure 1.4.

Loading...

Loading...