Page 12 of 35 Document No: 9961 Revision: F Issue Date: Jan-29-2018

This document and all copies are the property of Spider

®

. All dimensions and data are indicative only.

The user must ensure that the equipment complies with local rules and regulations.

®

The Spider

®

cages, and bosun chairs on, or in, buildings and structures. If these hoists are used for any other purpose,

you must take all necessary precautions to ensure that both the design and operation of the setup in which

Spider

®

current operating information prior to using this equipment. Call your local Spider

®

operations center.

®

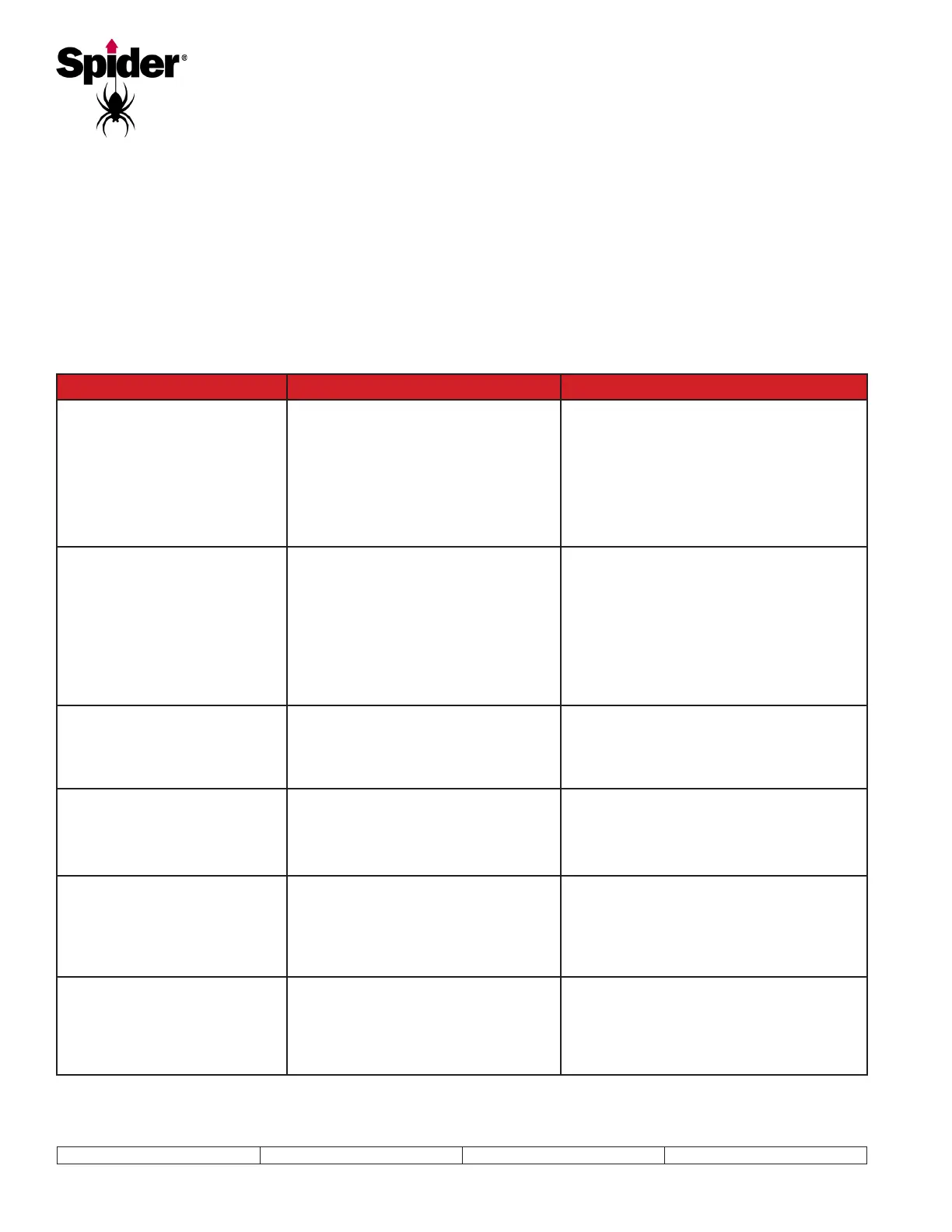

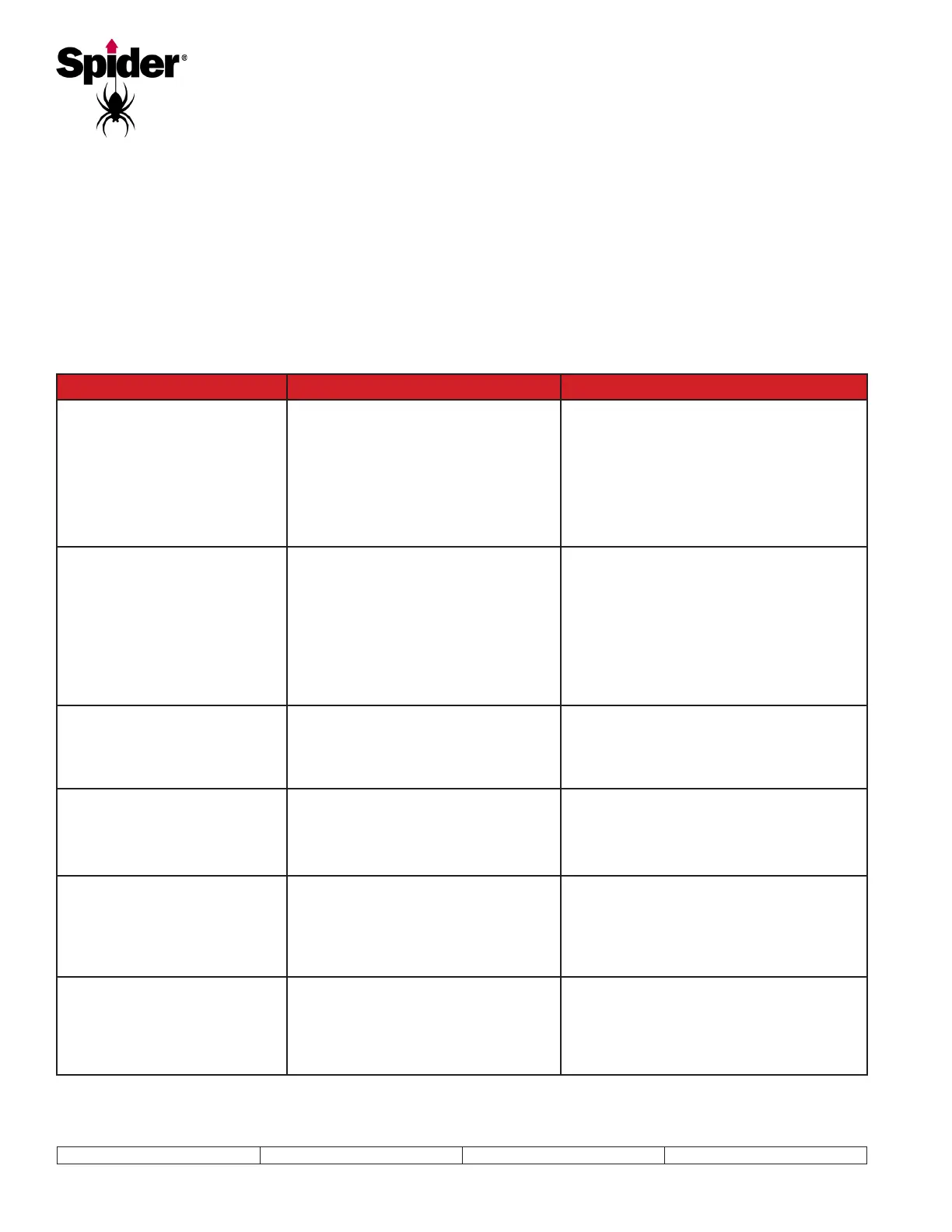

Feature Function

Operating Range: 208 V,

+10%/-15%

Proven reliable performance from

177 to 229 run volts

Tested in 30 min. continuous run

tests

Reduces service calls

Extends electric component life

Eliminates power-induced down time

Allows longer drops with yoked hoists

Saves time and money

Load-sensitive Traction Applies only the traction needed to

lift load, not full 1,000-1,500 lbs

lifting force on rope

Virtually eliminates the risk of

wire rope jams

Greater tolerance of wire rope

condition

Extends wire rope life by minimizing

wear and tear on rope

Prevents costly wire rope jams

Reduces the need for rescues

Controlled Descent Allows downward travel at a

controlled rate of speed in the

event of power loss

Eliminates need for rescue

Allows self-rescue of workers and

platforms

Built-in Overspeed Brake Stops hoist in overspeed condition

Can’t be left behind in shop,

bypassed, or dismantled

Ensures greater operator safety

Improved reliability

Noise Mitigation Package

(Optional upgrade for

hoists manufactured before

9/28/2015)

Eliminates wire rope noise that

sometimes occurs as hoist is

ascending

Quieter operation

Overspeed Trip Indicator

(Also an optional upgrade for

hoists manufactured before

9/28/2015)

DOWN button lights up red when

overspeed has been tripped and

DOWN circuit has been interupted

Gives the operator greater control and

understanding

Continued on next page

Loading...

Loading...