Waukesha Cherry-Burrell

®

Brand W70 Series Mix Proof Valves Maintenance

10/2023 95-03087 Page 25

Seat Cleaning Adjustment

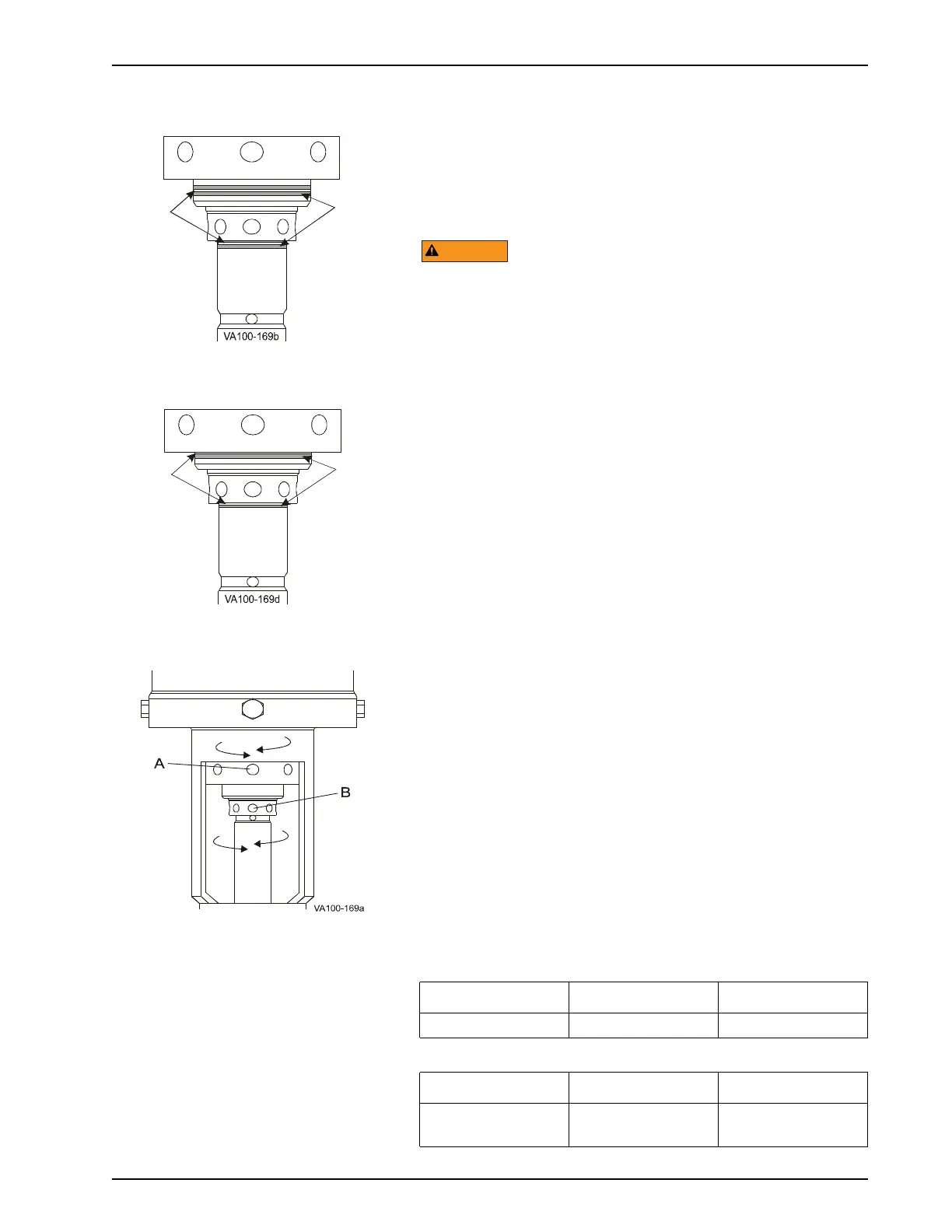

Seat lifting models are factory set. See Figure 17 and Figure 18.

Scribe lines (item A) within the acid-etched adjustment zone (item

B) provide a visual indication of the correct factory-set

adjustment. Screw the adjusting sleeve and adjusting nut until the

bottom edges align with the scribe line as shown in Figure 18,

item A.

NOTE: Always adjust the lower seat clean first.

Do not adjust the seat clean collars with pliers, vice-grips or

adjustable jaw pliers (channel locks).

If required, adjust the seat movement. With the valve closed,

using a 3/16" diameter pin spanner or Allen wrench, adjust the

movement of the seats to the factory settings or within the

adjustment zone (Figure 17 and Figure 18, item B). Once a

successful seat movement is established, clearly mark where the

bottom edges of the adjusting sleeve and adjusting nut align, to

ensure proper resetting after disassembly.

NOTE: For W72RSP valves built prior to November 2014, the

seat clean stroke is fixed at 0.12" upper and 0.28" lower. Confirm

the stroke length after proper assembly; tighten both stems

clockwise until they are stopped metal-to-metal.

Lower seat

Operate the lower seat clean cycle multiple times. Observe the

indicator stem movement at the top of the actuator, or at the

balancer on the bottom of the valve.

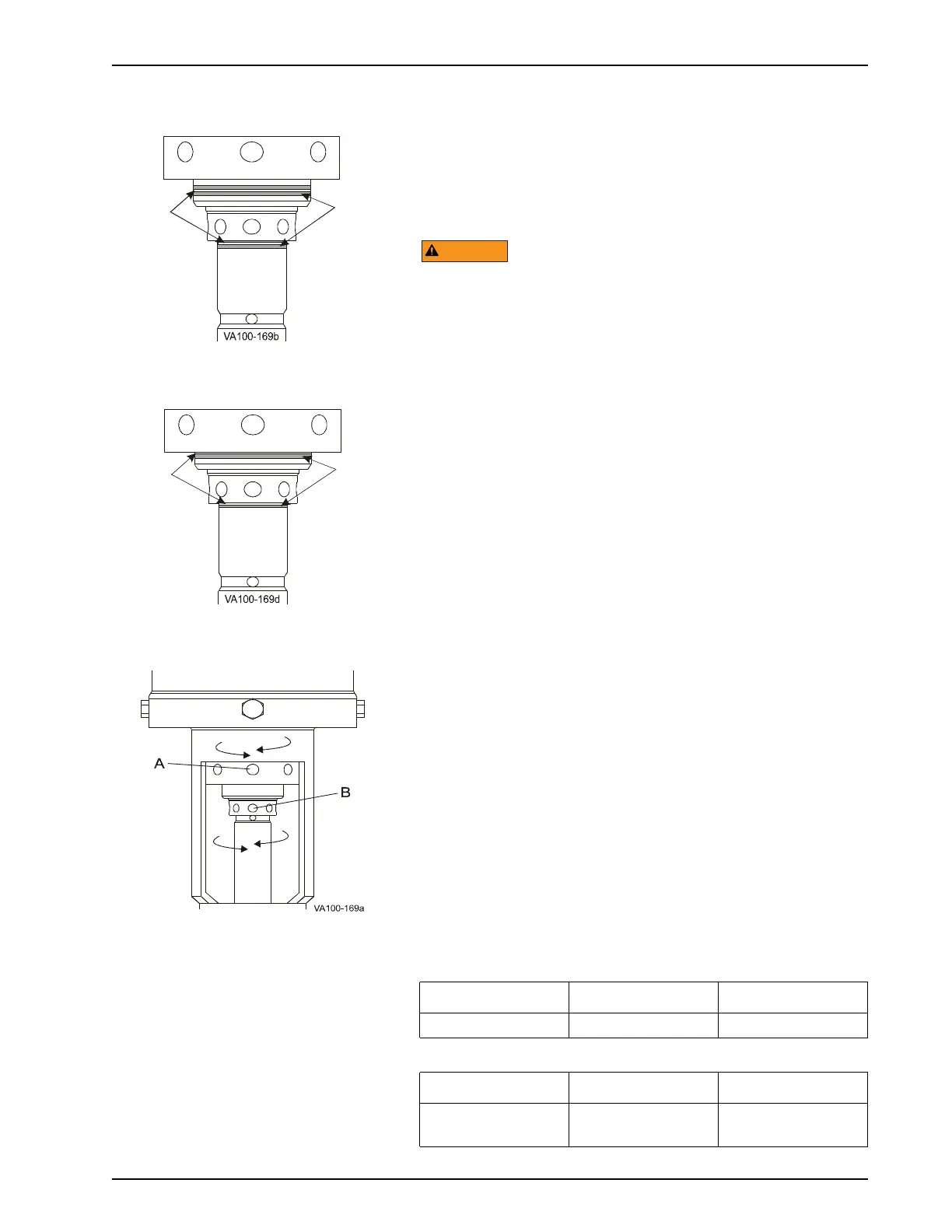

To adjust the movement of the lower seat for cleaning, rotate the

adjusting sleeve in the yoke (Figure 19, item B):

• W71/W73: Rotate right to increase; left to decrease.

• W72RS: Rotate left to increase; right to decrease. See also

“W72RS Lower Stem Measurement” on page 26.

Upper seat

Operate the upper lift cycle multiple times. Observe the outer

stem movement by watching the adjusting nut in the yoke (Figure

19, item A).

• To adjust the movement of the upper seat, rotate the

adjusting nut (Figure 19, item A) left to increase; right to

decrease.

Figure 17 - Adjustment zones

with scribe lines

Figure 18 - Bottom edges align

with scribe lines

A. Adjusting nut, upper seat

B. Adjusting nut, lower seat

Figure 19 - Location of Adjusting Nut

Table 4: Proper Seat Movement: W71/W73

Valve Size Lower Seat Upper Seat

1-1/2" - 4" 1/16" (1.59 mm) 1/16" (1.59 mm)

Table 5: P

roper Seat Movement: W72RS

Valve Size Lower Seat Upper Seat

1-1/2" and 2"

2-1/2" - 4"

1/8" (3.175 mm)

1/4"(6.35 mm)

1/8" (3.175 mm)

Loading...

Loading...