Maintenance Waukesha Cherry-Burrell

®

Brand W70 Series Mix Proof Valves

Page 36 95-03087 10/2023

Actuator O-ring and

Bearing Replacement

The valve stems and actuator must be removed from the valve

body before servicing the actuator components.

Although WCB fully-maintainable actuators are designed with a

contained spring for safety, always use caution when handling

any piston/spring assembly as any compressed coil spring can

be extremely dangerous.

NOTE: Do not pressurize the actuator with air when the stems

are removed. This may tear the O-rings and cause the actuator to

leak air when it is re-assembled.

NOTE: If present, the control module must be removed to replace

the O-rings and bearings in the top of the cylinder assembly.

Please refer to control module publication 95-03083.

NOTE: For larger drawings and complete part lists, see “W71/

W73 Non-Seat Lift Actuator” on page 84 and “W72RS Non Seat

Lift Actuator” on page 88.

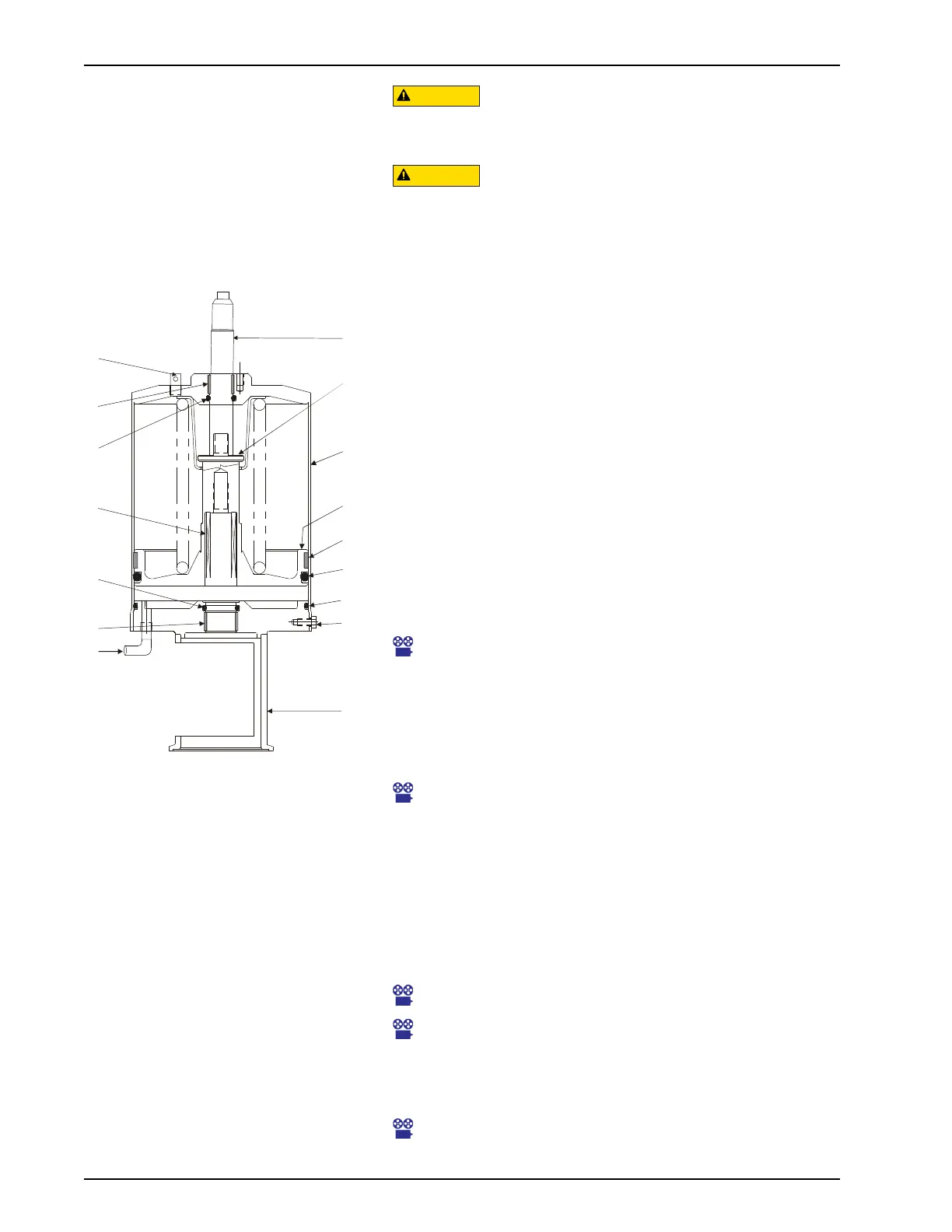

Removal of O-rings and Bearings, Non-Seat Lifting

Actuators

Non Seat Lifting Actuators

1. For non-seat lifting valves, remove the cap screws (Figure

35, item 9) and remove the yoke (item 12) from the cylinder

assembly. Set the yoke aside.

Maintenance Video 14: Actuator disassembly; lower

cartridge removal

2. Pull the piston and spring assembly (Figure 35, item 10) from

the cylinder assembly.

3. Inspect the four O-rings (Figure 35, items 6, 7, 8, and 11).

Replace them if they are worn or damaged.

Maintenance Video 16: Removal of main piston, lower seat

lift piston

4. Inspect the three bearings (Figure 35, items 5, 14, and 15). If

the bearing does not extend slightly above the edge of the

metal surface, replace the bearing.

5. The bearing is split to allow its removal from the groove.

Place a screwdriver or pick behind the bearing and pry it

away from the wall of the yoke or cylinder cap. A needle-nose

pliers can be used to grip the bearing for removal.

Maintenance Video 17: Main piston O-ring removal

Maintenance Video 18: Main piston O-ring replacement with

bearing

6. Assemble the stack components as shown in Figure 35.

Install the yoke and cap screws.

Maintenance Video 22: Using insertion sleeve for W71/W73

Actuators

Figure 35 - W71/W73 Actuator Assem-

bly (Non-Seat Lift Valve)

VA100-430

5

6

18

11

15

33

9

7

8

14

10

4

12

1,1a

13

31

NOTE: The bearing will be damaged

during removal and must be replaced

with a new bearing.

NOTE: Installation of the piston and

spring assembly on 4" actuators

requires a special sleeve to contain

the bearing on the piston while

installing the assembly. See Figure 37

and Figure 38 on page 38.

Loading...

Loading...