Maintenance Waukesha Cherry-Burrell

®

Brand W70 Series Mix Proof Valves

Page 26 95-03087 10/2023

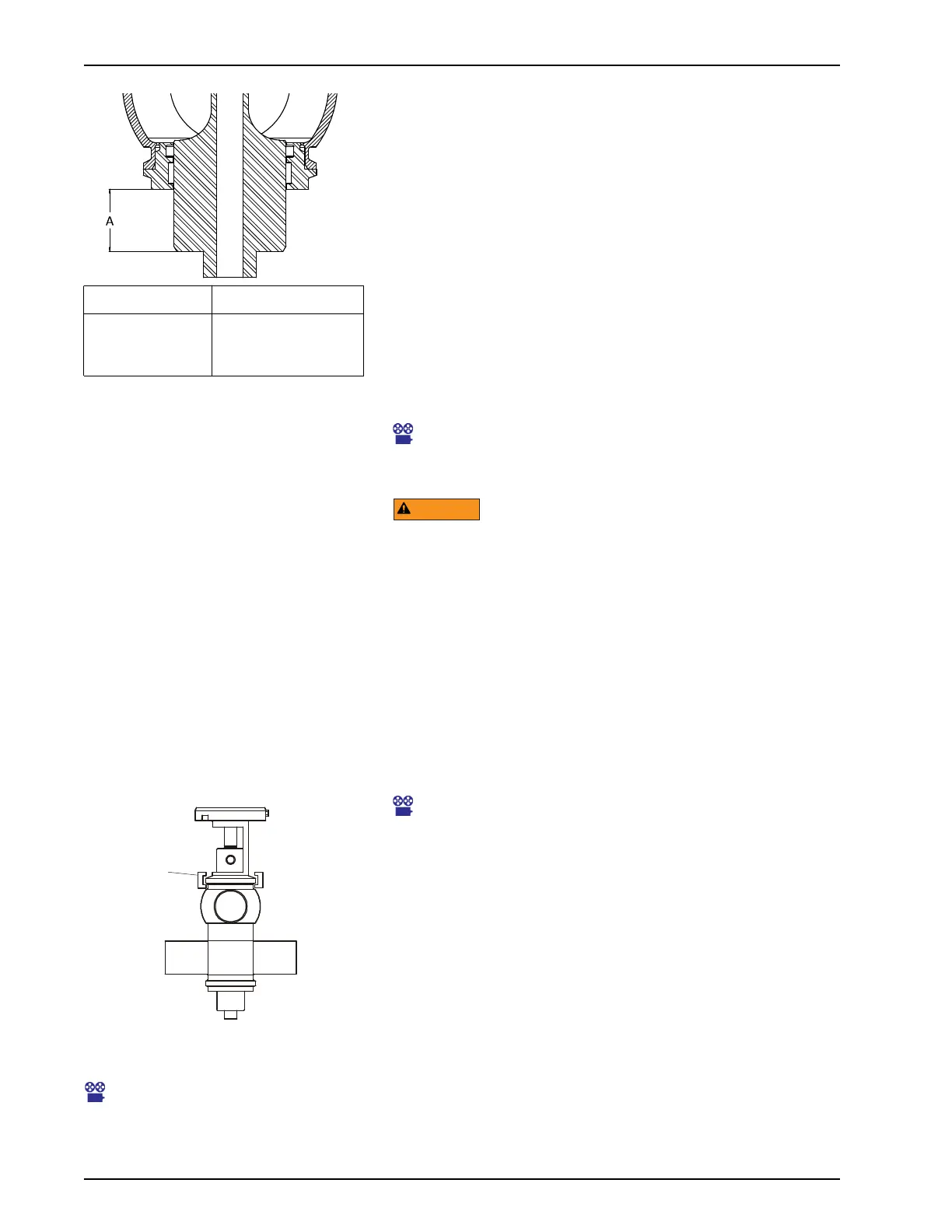

W72RS Lower Stem Measurement

For the W72RS models, the location of the lower stem is more

critical than the stem travel. Confirm the proper location of the

lower stem by measuring the distance from the lower seal

retainer to the lower shoulder of the stem (Figure 20, dimension

“A”) when the valve is static.

• To increase this measurement distance and allow more

cleaning of the lower seat, turn the adjustment sleeve to the

left.

• To decrease the distance and allow less cleaning of the lower

seat, turn the adjustment sleeve to the right.

Removing Valve from

System

This icon indicates a link to a maintenance video available

online. To access the PDF online, go to: www.spxflow.com/

en/assets/pdf/95-03087_w70mixproofv_wcb.pdf.

NOTE: If the valve has a control module

with a solenoid, the air and electric can

remain ON to assist with removal of the

valve from the body.

NOTE: On seat lifting model valves,

clearly mark on the other stem and

adjusting threads where the bottom

edges of the adjusting sleeve and

adjusting nut align to ensure proper

resetting of seat movements after

disassembly.

1. Clean, rinse, and drain the pipe system elements attached to

the valve. Remove or block the fluid and gas lines to prevent

material from entering the pipe system elements attached to

the valve. If present, disconnect the flush water supply

connection. If supplied, seat lifts can be used to check for

pressurization of the pipeline.

2. Disconnect the external flush if used.

3. Supply air to open the valve.

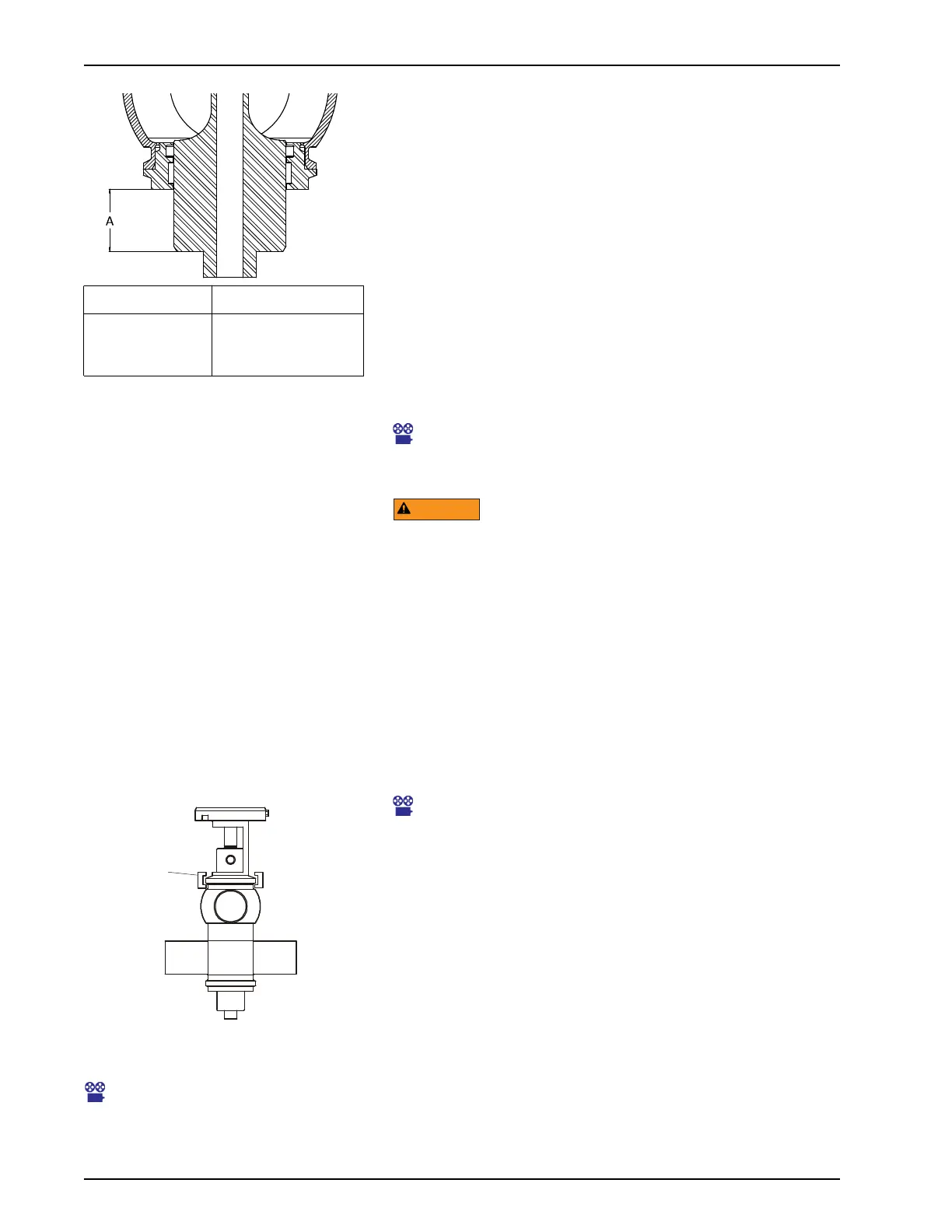

4. Remove the clamp between the yoke and the adapter (Figure

21, item A).

Maintenance Video 1: Remove valve from body

5. Remove the air pressure to cycle the valve closed, lifting the

valve approximately 3/8" (9.5 mm) out of the body. Shut off

and disconnect the air supply.

6. Disconnect and lock out electrical power to the valve.

7. Lift the complete valve actuator and stems out of the valve

body, being careful not to damage the stems or internals.

8. Move the valve to a work station.

9. Re-install in reverse order. Keep in mind that air must be

applied to cycle the valve open and lower the valve insert

approximately 3/8'', in order to completely reseat the valve in

the body.

Maintenance Video 2: Re-install

valve into body

10. Re-fasten the clamp between the yoke and the adapter

(Figure 21, item A), then remove the air pressure to cycle the

valve closed.

W72RS Size Dim. “A”

2"

2-1/2" and 3"

4"

1-1/3" (33.87 mm)

1-3/4" (44.45 mm)

2-1/8" (53.98 mm)

Figure 20 - W72RS Lower Stem

Before removing the actuator/valve stem assembly from the valve

body, drain all product lines connected to the body.

Figure 21 - Location of Adapter Clamp

Loading...

Loading...