Waukesha Cherry-Burrell

®

Brand W70 Series Mix Proof Valves Operation

10/2023 95-03087 Page 17

Operation

All functions of W70 Series Mix Proof valves are pneumatically

controlled using a 75 min. to 90 max. psi (5.2 to 6.2 bar) clean air

supply.

The valve contains a large and small spring in the valve actuator.

The springs compress the valve seats to seal closed.

Large Spring

• Located in top air chamber of cylinder.

• Holds valve in the closed position.

Small Spring

• Located in the extended hub of the upper piston.

• When the valve is open, the spring acts on the upper seat

stem to hold the upper and lower plugs together.

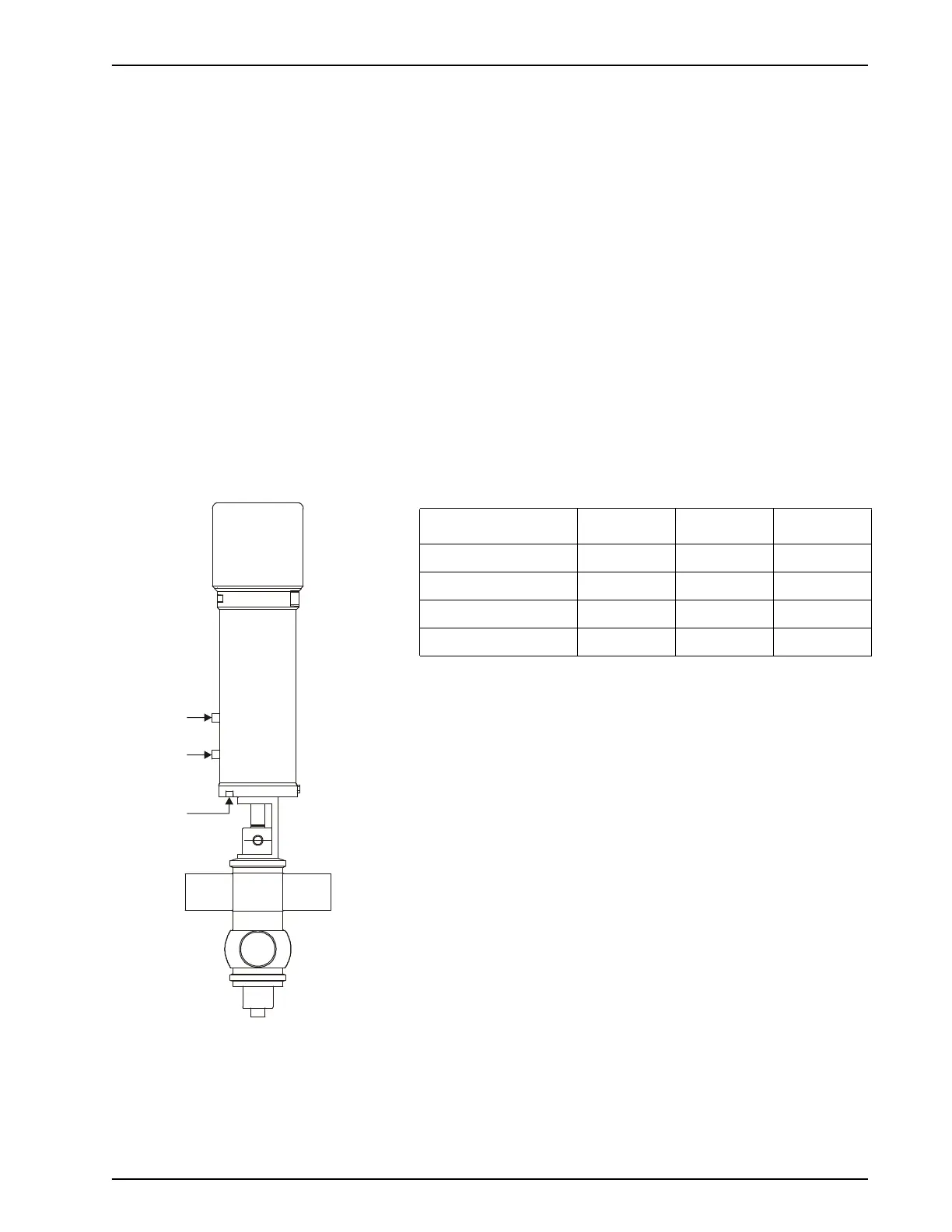

Solenoid Valve Port

Connections

Up to three air supplies controlled by solenoid valves supply air to

the valve actuator (Figure 10).

1 = Valve Open Inlet Solenoid

2 = Upper Seat Clean Inlet Solenoid*

3 = Lower Seat Clean Inlet Solenoid*

ON = Solenoid energized (OPEN). LED is lit.

OFF = Solenoid de-energized (CLOSED). LED is off.

Solenoids are normally closed.

Air connections are 1/8" NPT x 1/4" push-to-connect poly tube

fittings.

* Seat lifting is an option which requires (2) two additional air

supplies. Non-seat lifting valves (NSL) only have one air inlet (1).

For specific air-routing and solenoid porting, please refer to

control module publication 95-03083.

Figure 10 - Solenoid Valve Port

Connections

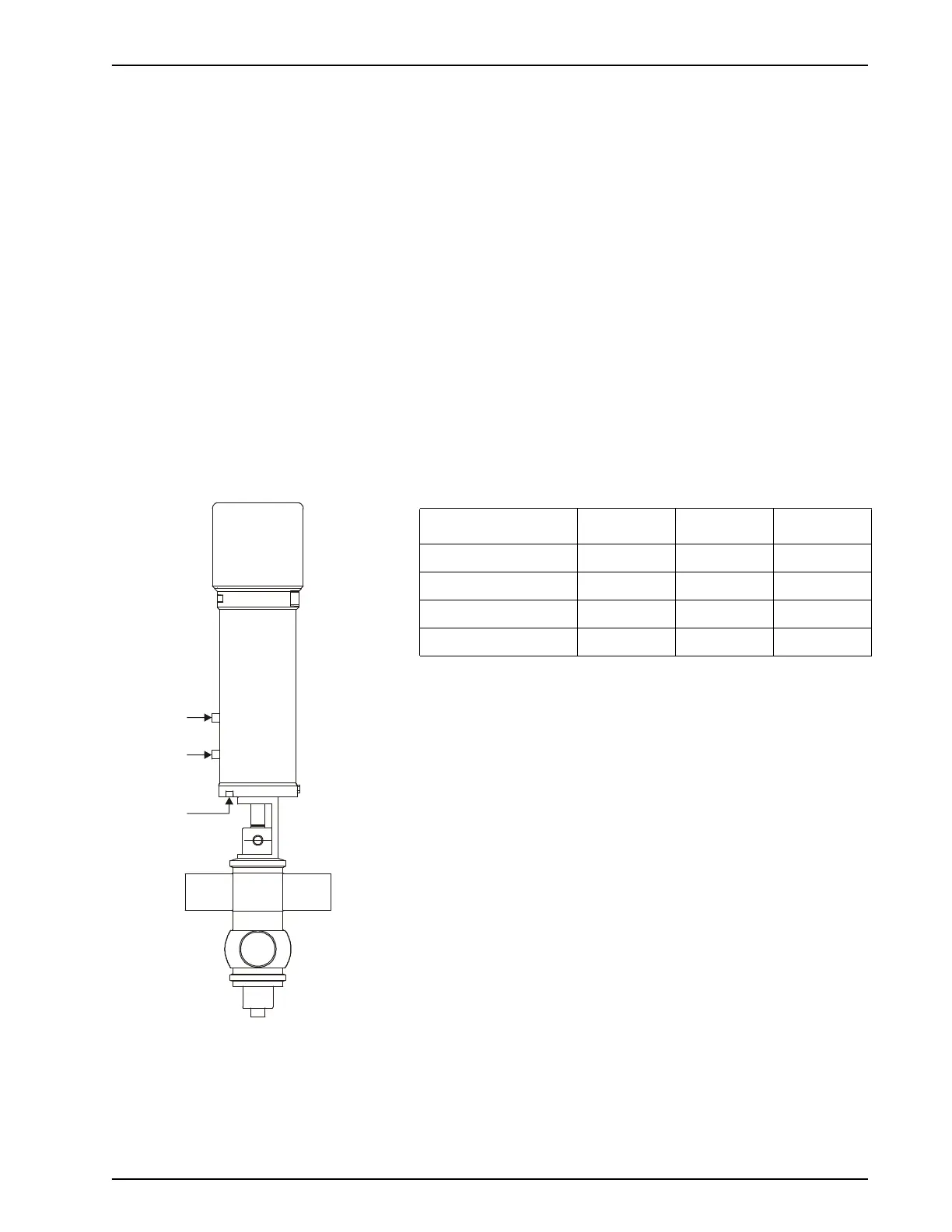

Table 3: Solenoid/Valve Position

Condition Solenoid 1 Solenoid 2 Solenoid 3

Closed OFF OFF OFF

Open ON OFF OFF

Upper Seat Clean * OFF ON OFF

Lower Seat Clean * OFF OFF ON

Loading...

Loading...