Waukesha Cherry-Burrell

®

Brand W70 Series Mix Proof Valves Installation

10/2023 95-03087 Page 15

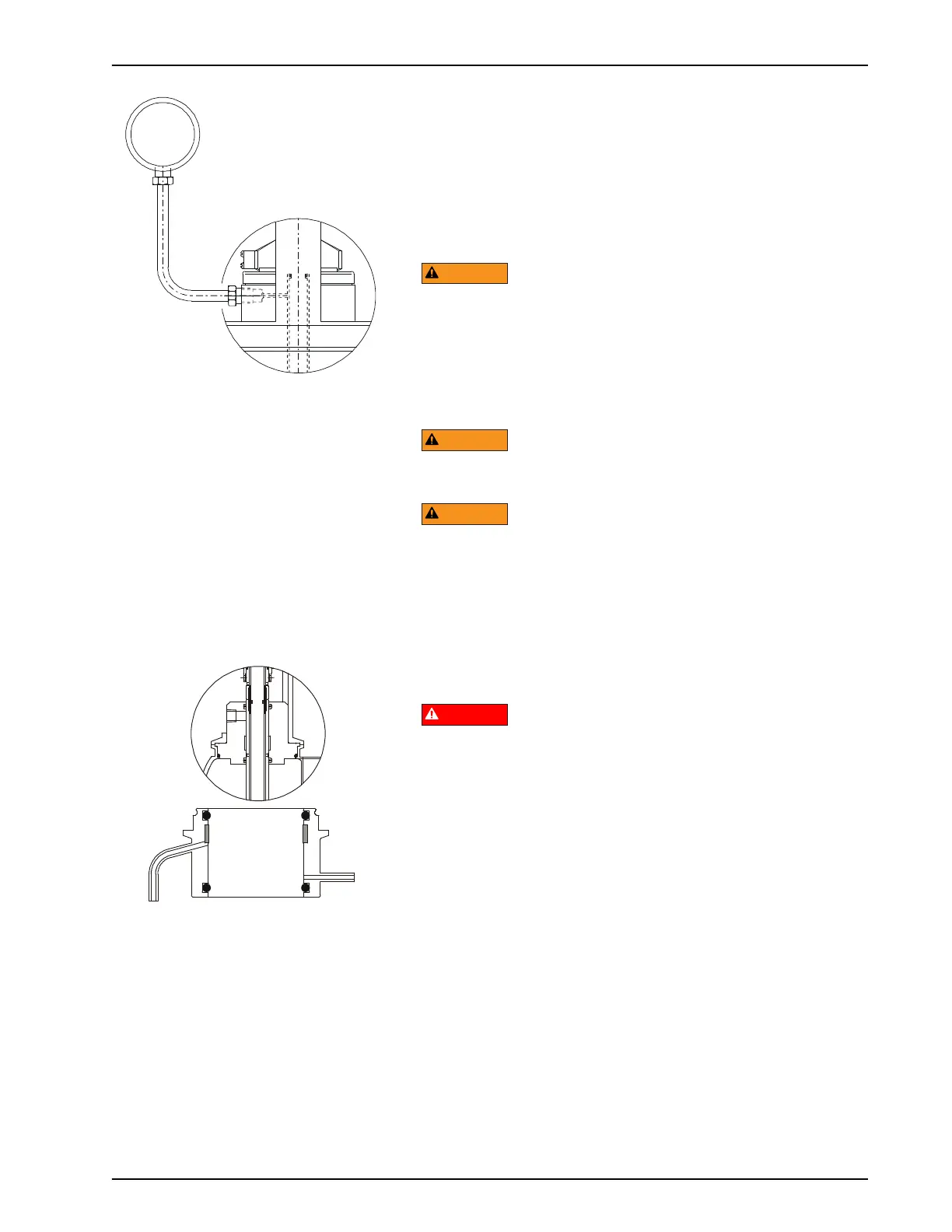

Connect the cavity cleaning supply to a suitable liquid supply to

flush the vent/drain (Figure 7) during the operation of the

processing system.

The flush supply line can be connected to the pipe system by 1/4"

(6 mm) rigid or poly flow tubing. The flush supply is blocked when

the valve is open.

Connect the supply line to the adapter connection with poly flow

tubing (Figure 7).

During CIP cleaning and valve opening (W71/W73), fluid escapes

from the drain port. Drain this off to prevent a possible hazard to

personnel.

Regulate the flush supply (Figure 7, item A) for pressures of 30

psi minimum, 50 psi maximum.

The maximum solution temperature is 180°F (60°C).

Cavity cleaning operation must fall within the fail-safe control sys-

tem. See “Cleaning” on page 23.

Take proper precaution to safeguard the flush water supply, such

as installing backflow prevention devices.

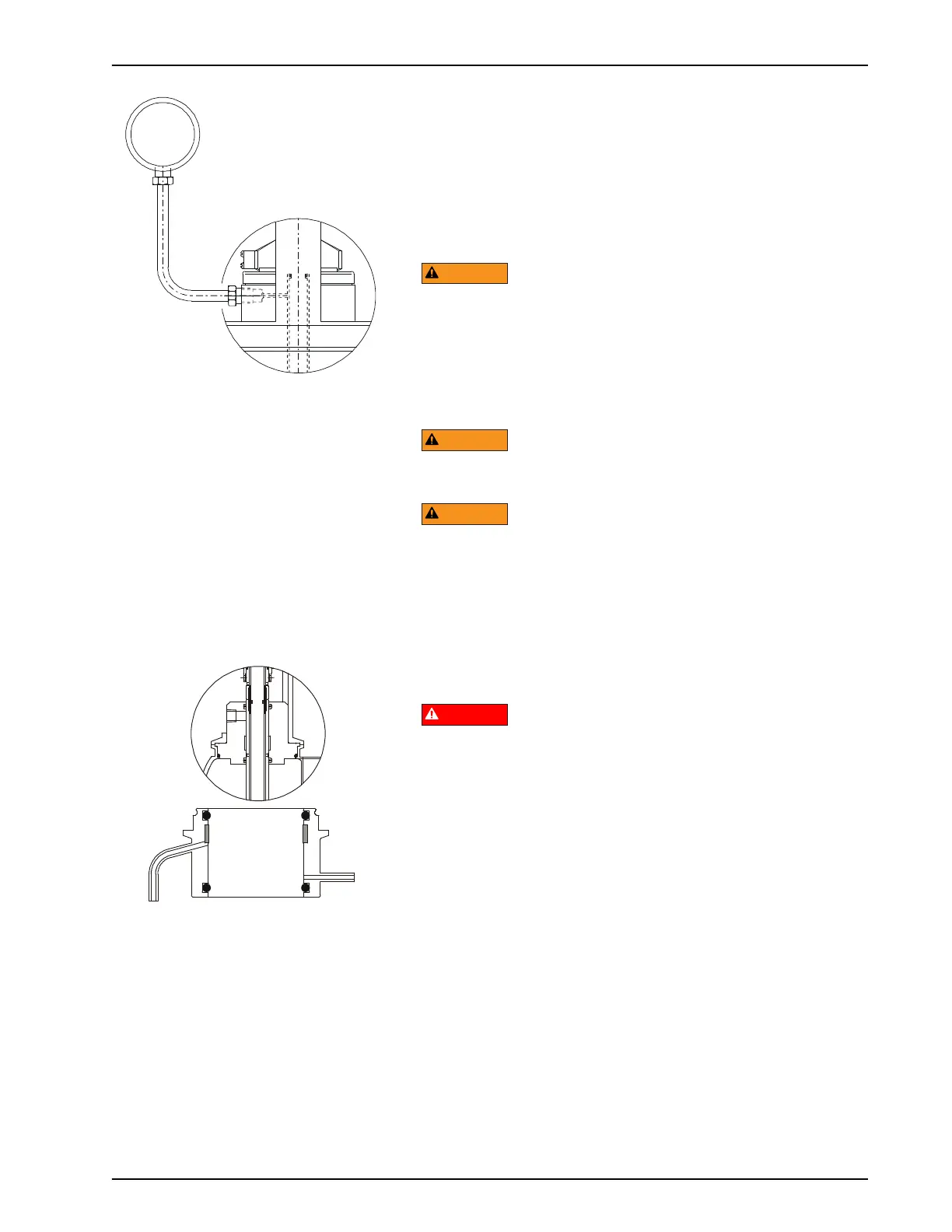

External Flush - Steam

Vent Cavity

Steam Vent Cavity, Upper and Lower Stem

Use both Upper Stem Steam Flush Adapter and Lower Stem

Steam Adapter.

This option allows continuous steaming of the vent cavity (in both

open and closed positions), upper and lower stems.

Valves equipped with the steam flush option for stem and vent

cavity can produce high temperatures and steam hazards that

may result in personal injury or death.

To steam flush the upper and/or lower stem as well as the vent

cavity, the Mix Proof Valve must be ordered with the Steam Flush

for stem and vent cavity. This option (See Figure 9 on page 16)

contains the following components:

• External flush connection, 1/4" NPT.

• Modified adapter with removed O-rings to flush the stem.

• Jacket with 1/4" Tube (S.S.) on lower balancer to flush the

lower stem (balancer).

• EPDM gaskets for all seals in the wetted area.

Figure 7 - Connection of Flush Supply

Figure 8 - External Steam Barrier -

upper stem

Loading...

Loading...