Maintenance Waukesha Cherry-Burrell

Page 32 95-03009 10/2010

Maintenance

Scheduled Maintenance A routine maintenance program can extend the life of your pump. Make

sure to keep maintenance records. These records will help pinpoint

potential problems and causes.

Routine Maintenance

Your scheduled routine maintenance should include the following items:

• Check for unusual noise, vibratio

n, and bearing temperatures

• Inspect the pump and piping for leaks

• Check the Mechanical Seal area for leakage

(No leakage is desired)

• Check the backplate gasket for wear/damage

• Bearing lubrication (See motor manufacturer for correct

spec

ifications)

•

Seal Monitoring

• Vibration analysis

• Check the discharge pressure

• Temperature monitoring

Disassembly of Pump With

a Type 1 Seal

1. Shut off the product flow to the pump and relieve any product pres-

sure.

2. Shut off and lock out power to the pump.

3. Disconnect the suction and discharge p

ipe fittings.

4. Remove the casing clamp and casing.

5. Slide the o-ring off of the backplate.

6. Remove the impeller retainer bolt and shaft o-ring.

NOTE: The

re

tainer bolt has standard right-hand threads.

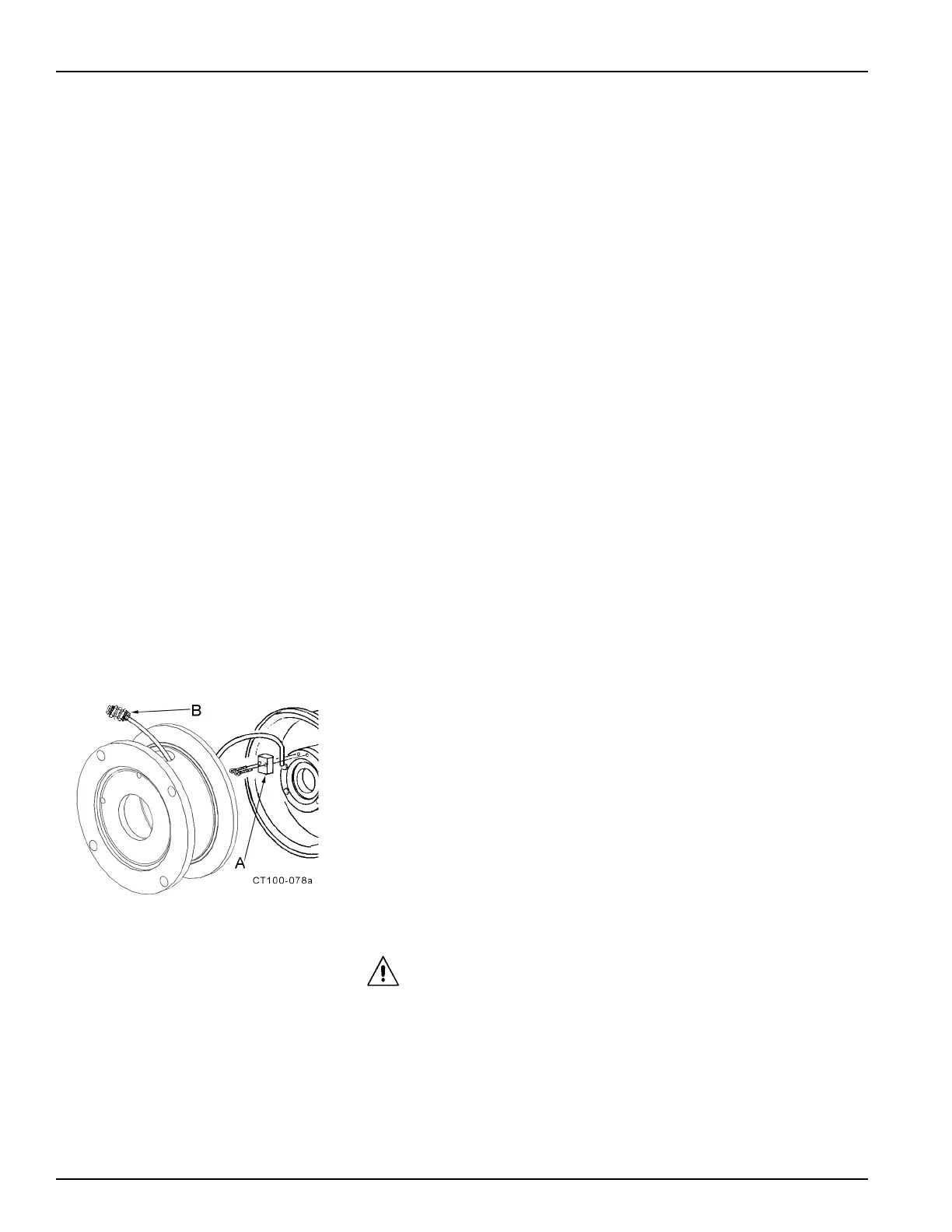

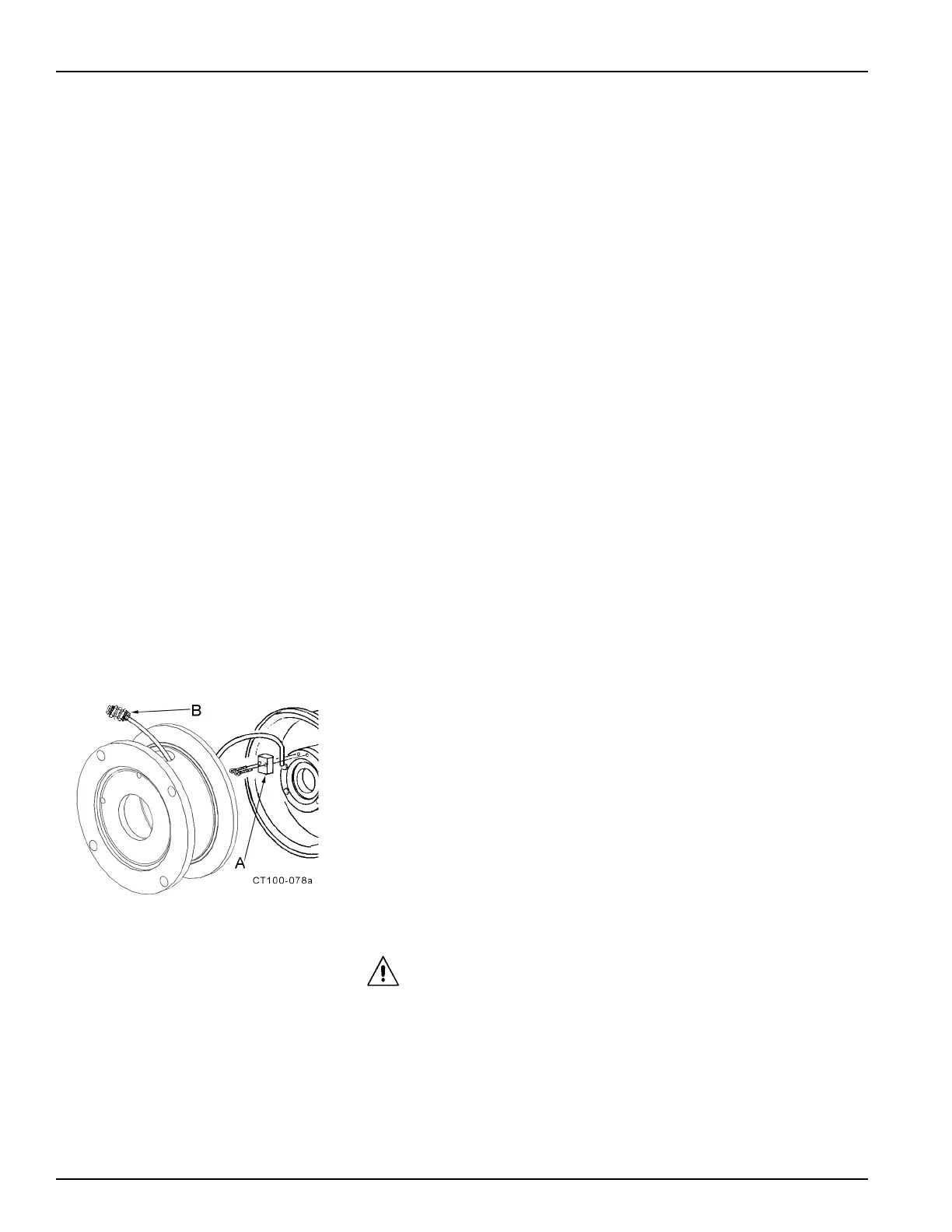

Removal of the Water Cascade

1. Loosen the socket head screws holding the water cascade block on

the stationary seat retainer and remove the plastic hose.

2. Pull off the impeller/backplate assembly and place it on a clean flat

surfac

e with the impeller shaft up.

CAUTION: Handle the impeller/backplate assembly with care to

prevent damage to the seal components.

NOTE: If the assembly cann

ot be removed from the motor shaft by hand,

contact Waukesha Cherry-Burrell Customer Service.

Figure 23 - Removal of the Water Cascade

System

Loading...

Loading...