Maintenance Waukesha Cherry-Burrell

Page 46 95-03009 10/2010

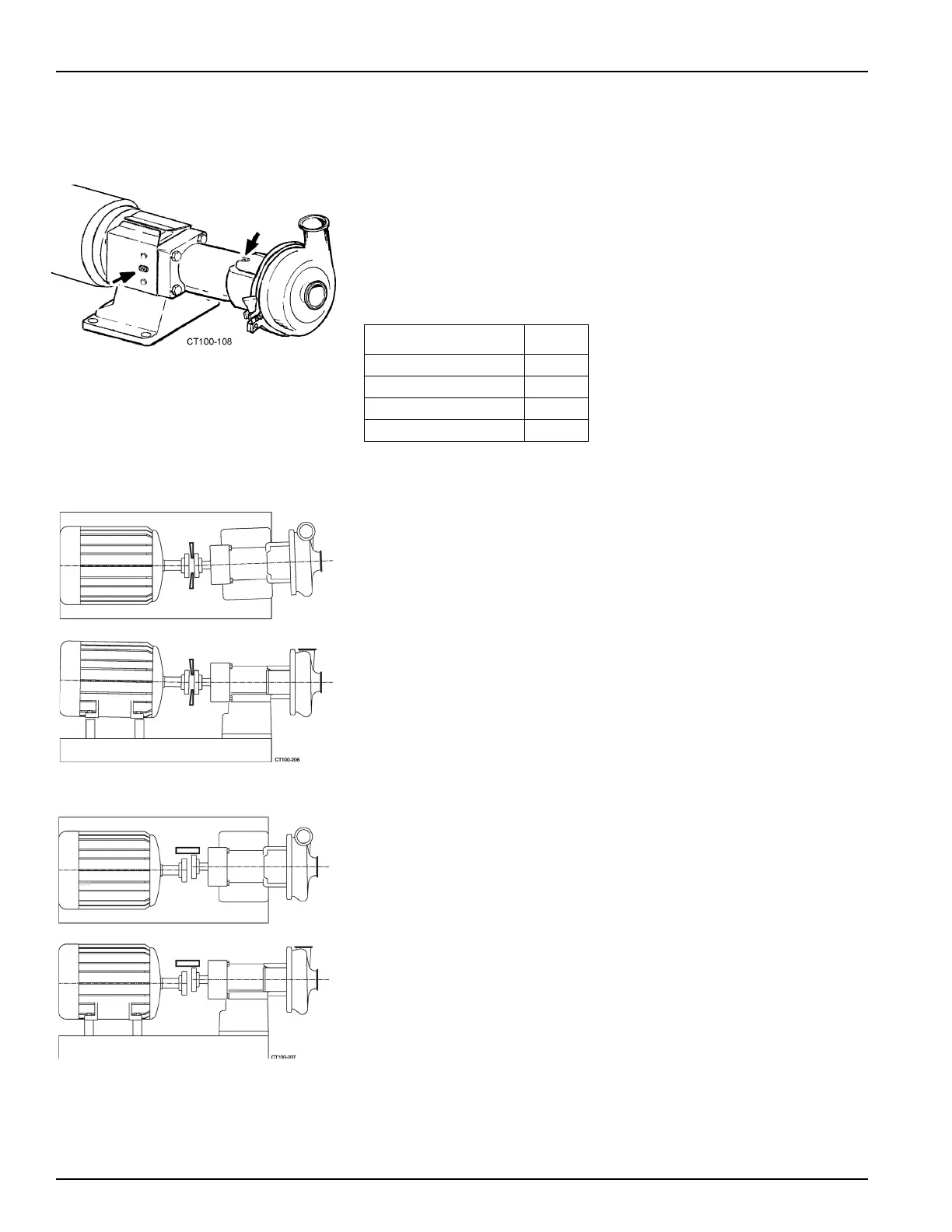

Pedestal Base-Mounted

Pump Housing Lubrication

Waukesha Series 200 Pedestal Pumps are lubricated with NLGI grade 2

Lithium Complex Grease. Use only NLGI grade 2 Lithium Complex thick-

ened greases to replenish the bearing grease supply. The location of the

grease

fittings is indicated in Figure 62.

NOTE: Combining greases that will not mix with the products above can

change the viscosity/consistency of the grease, resulting in bearing dam-

age. If there is doubt, remove the bearings, clean, and re-pack them.

For compatible lubricants, contact Waukesh

a Ch

erry-Burrell Application

Engineering at 1-800-252-5200 or 262-728-1900.

Lubrication Schedule

Size/RPM Hours

NOTE: If operating

tempera-

tures are over 158°F (70°C),

reduce

hours by half for every

27°F (15°C) over the operat-

ing temperature.

Small Bore/1750 RPM 4400

Small Bore/3500 RPM 2000

Large Bore/1750 RPM 2000

Large Bore/3500 RPM 1000

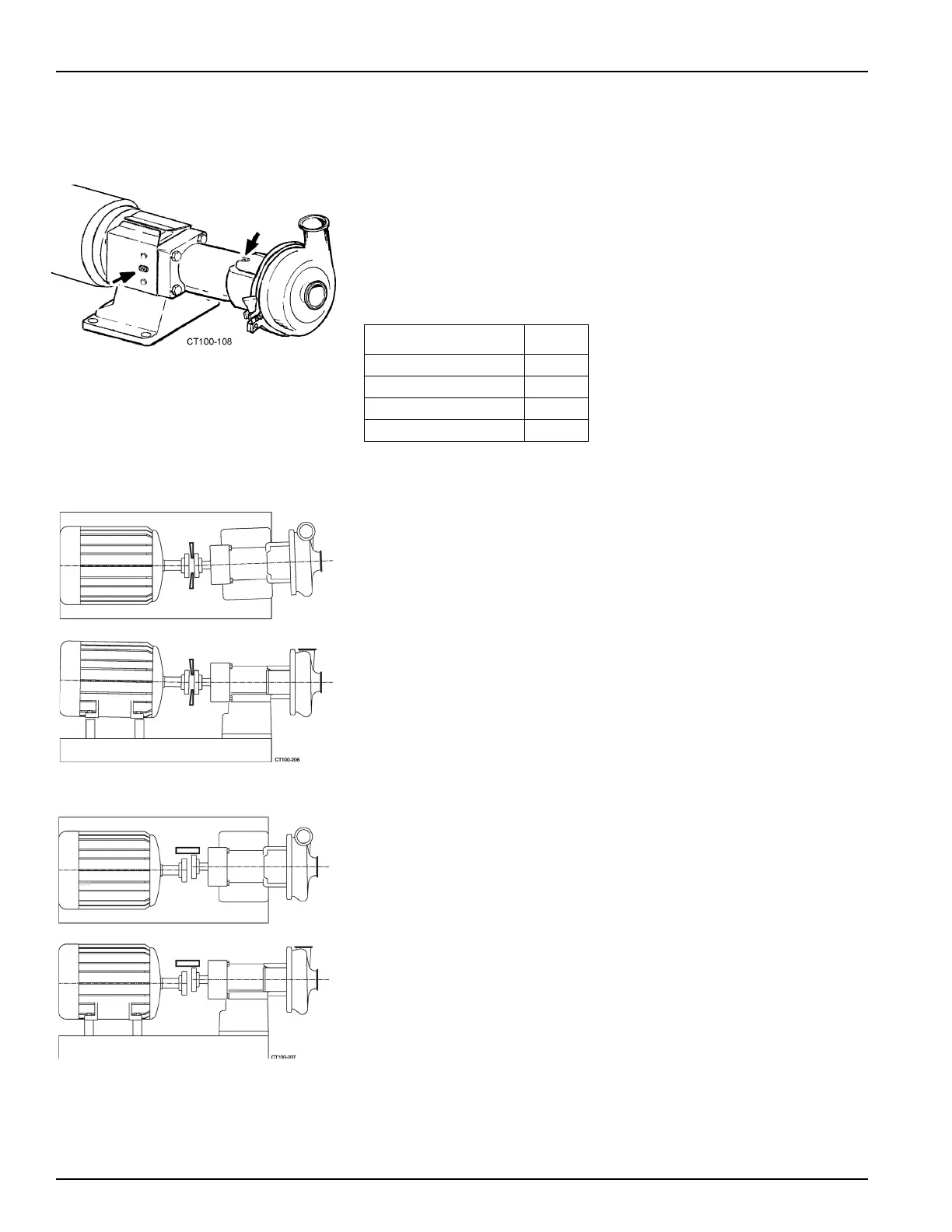

Pump Alignment

A flexible coupling is used to compensate for end play and small differ-

ences in alignment. The pump and drive shaft should be aligned as

closely as po

ssible.

Checking Angular Alignment

Using feeler gauges or taper gauges, adjust to get equal dimension at all

points. At the same time, set space between the coupling halves to the

manufacturer’s recommended distance.

Checking Parallel Alignment

Using straight edges and shims, move the drive and shim height as

needed.

Figure 62 - Grease Fittings on the Pedestal

Pump

Figure 63 - Checking Angular Alignment

Figure 64 - Checking Parallel Alignment

Loading...

Loading...