6 Quick start

This section describes how to start with STLINK-V3PWR to make power measurements:

1.

Check that the bundle is complete (STLINK-V3PWR with three flat cables and a bundle of four wire

jumpers).

2. Install or update the power measurement software (for example STM32CubeMonitor-Power).

3. Connect a USB Type-C

®

to USB Type-C

®

cable (recommended) or USB Type-A to USB Type-C

®

cable

between STLINK-V3PWR and the PC (refer to Section 5.3 USB connection with a host PC).

4. Check the LED status:

– The USB LED must turn green: STLINK-V3PWR is supplied by a valid power source from PC.

– The COM LED must turn red: STLINK-V3PWR debugger is ready.

5. Hardware configuration for power measurement: Connect the STLINK-V3PWR’s SMU (OUT and GND)

onto the power supply input of the target application using wire jumpers. Refer to Section 6.1 Typical

application.

6. Software configuration for power measurement: Refer to Section 6.2 Software configuration.

6.1 Typical application

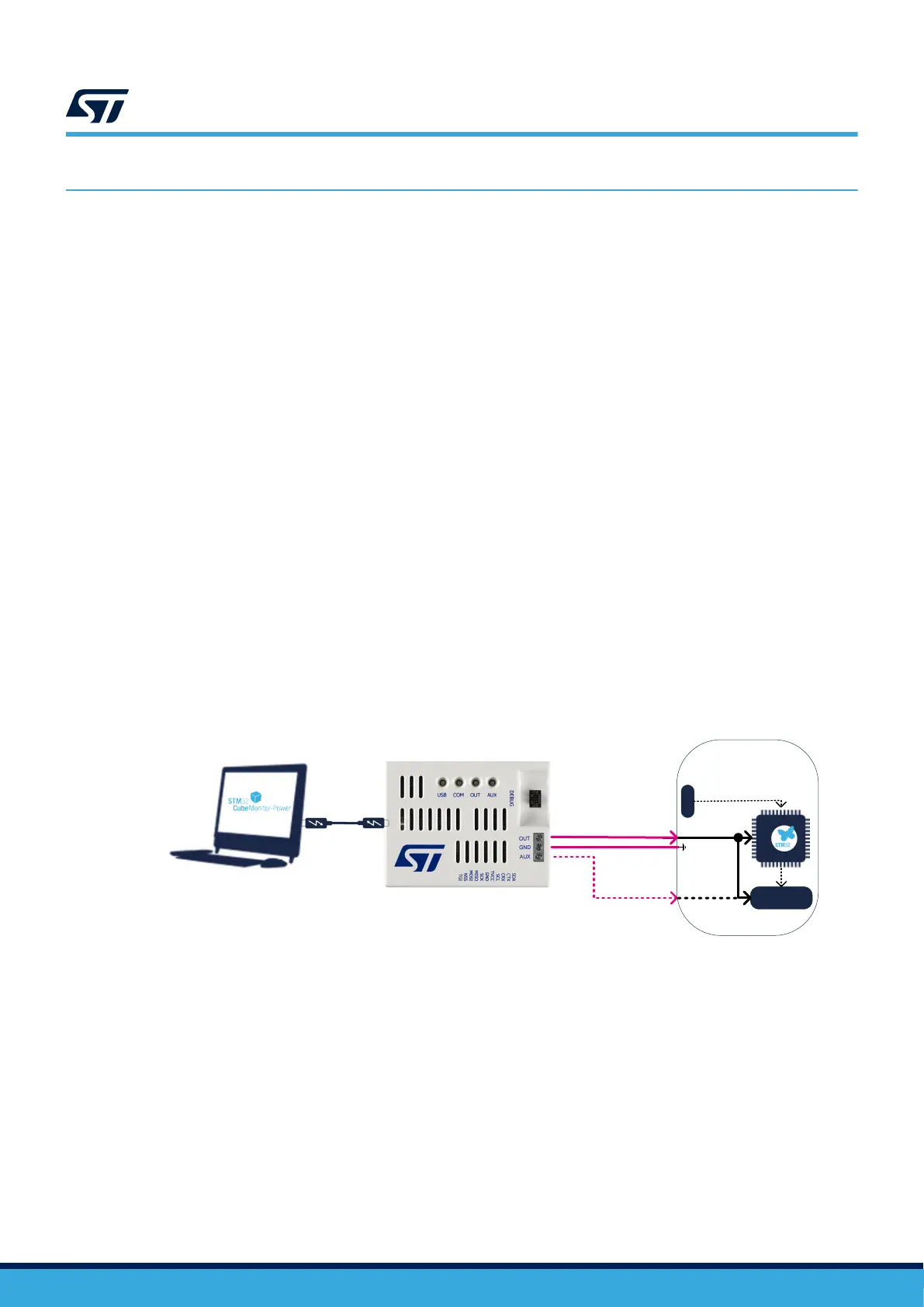

6.1.1 Connection with a target application for power measurements

STLINK-V3PWR provides two voltage‑regulated power sources: OUT and AUX:

•

OUT is a programmable voltage‑regulated power source including current measurement: Refer to

Section 7.2 SMU output (OUT).

• AUX is a programmable voltage‑regulated power source only: Refer to Section 7.3 Auxiliary power source

output (AUX).

Figure 4 provides a basic connection example of STLINK-V3PWR with a target application.

Figure 4. STLINK-V3PWR connection

DT59118V1

VDD

Peripherals

Target

appl

ication

optional

+3V3

VDD

3V3_PERIPH

DEBUG

debug I/F

ctrl I/F

GND

• Connect OUT to the target application power supply input to be measured (for example pin +3V3 of an

STM32 Nucleo board) using a wire jumper provided in the kit.

•

Connect the GND to the target application ground (for example pin GND of an STM32 Nucleo board) using

a wire jumper provided in the kit.

• (Optional) Connect the AUX power source to the target application input power supply that does not require

to be measured.

6.1.2 Recommendations for power measurements

The use of wire jumpers provided in the kit must be limited to target applications not consuming more than

100 mA to avoid voltage drop through wire jumper cables.

UM3097

Quick start

UM3097 - Rev 1

page 9/30

Loading...

Loading...