Controller Operation

Instruction Manual

23

SOC: Shutoff Code, see section “2.7.7.2 Shutoff Codes” on page 23

Job Count: The active fastener number for the Job.

Task Count: The active fastener number for the Task.

Tool Model: The model number of the tool used during this fastening cycle.

Tool Serial: The serial number of the tool used during this fastening cycle.

Tool

Temperature:

The temperature of the tool at shutoff.

Part ID: The value in the Part ID buffer when the fastening cycle ran.

Steps: List the steps used during the fastening cycle. The Audit step

values are in Bold.

TC/AM The Strategy or Smart Step used in the current step.

Torque: The Torque value achieved in the current step.

Angle The Angle value achieved in the current step.

Current The Current value achieved in the current step.

Rate The Rate value achieved in the current step (if enabled)

Deviation The Rate Deviation achieved in the current step (if enabled)

Use the up/down arrows to scroll through the Details.

Press the interactive BACK button to return to the Fastening Cycle Log.

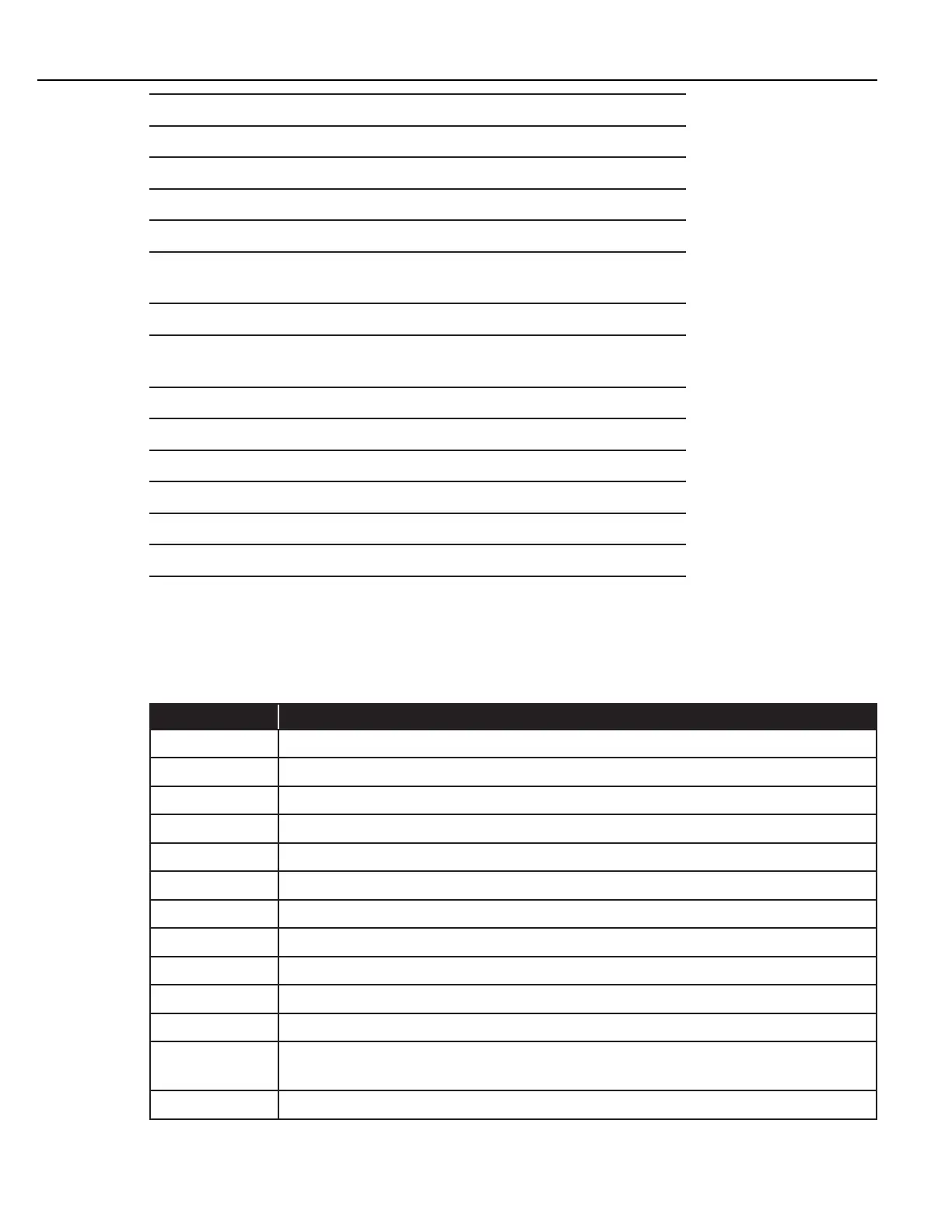

2.7.7.2 Shutoff Codes

Shutoff Codes on the display indicate why a fastening cycle terminates prior to completion.

Shutoff Code Description

TIME Fastening cycle time exceeds programmed Cycle Abort time value.

STOP Spindle stopped by either the operator or other device.

>115% Spindle stopped due to torque achieving greater than 115% torque limit for the tool.

FAULT The tool shutoff due to a Fault. See section “2.8 Faults” on page 25.

STALL Spindle stopped due to a stall.

SYNC Spindle failed fastening cycle due to a synchronization error.

T1≠T2 Primary and secondary redundant transducer values are outside comparative limits.

A1≠A2 Primary and secondary redundant angle values are outside comparative limits.

TD Spindle stopped due to torque dropping below Torque Drop Threshold

YIELD Spindle stopped due to bailout on detecting yield during an Angle Control strategy.

[T] A torque/angle window violation for the Torque Monitoring portion of the fastening cycle.

RATE

Torque Rate has exceeded the High Limit or not achieved the Low Limit during a Rate

Monitoring portion of the fastening cycle.

I Current has exceeded the High Current Limit or not achieved the Low Current Limit.

Loading...

Loading...