Programming

Instruction Manual

55

BARCODE /

PRINTER

The port performs both functions at the same time.

Barcode: The port reads input from a barcode scanner and places it into the PART ID

buffer. Data in the PART ID buffer is added to the fastening cycle data when stored and

transmitted via a network protocol or printed.

Print: A pre-defined data string is sent out the port after each fastening cycle that

exceeds the Threshold Torque. See section “6.4 Serial Connector” on page 113 for string

definitions.

Baudrate The data transmission rate in bits/second for communication.

Parity Used to determine if data was lost or compromised during transfer.

TOYOTA PI Connects this port to the Toyota PI box.

PFCS Connects this port to the Chrysler network.

OPEN Connects this port to a network using the OPEN protocol with serial messaging.

PLC

The internal PLC takes over communications on this port. Baud rate and Parity of the

Serial port may be changed for PLC communications. Set these values according to the

requirements of the end user.

Baudrate The data transmission rate in bits/second for communication.

Parity Used to determine if data was lost or compromised during transfer.

Use the right arrow to move to the next tab or press EXIT to save the changes and return to the Run screen. See

section “3.1.2.6 Exit” on page 52.

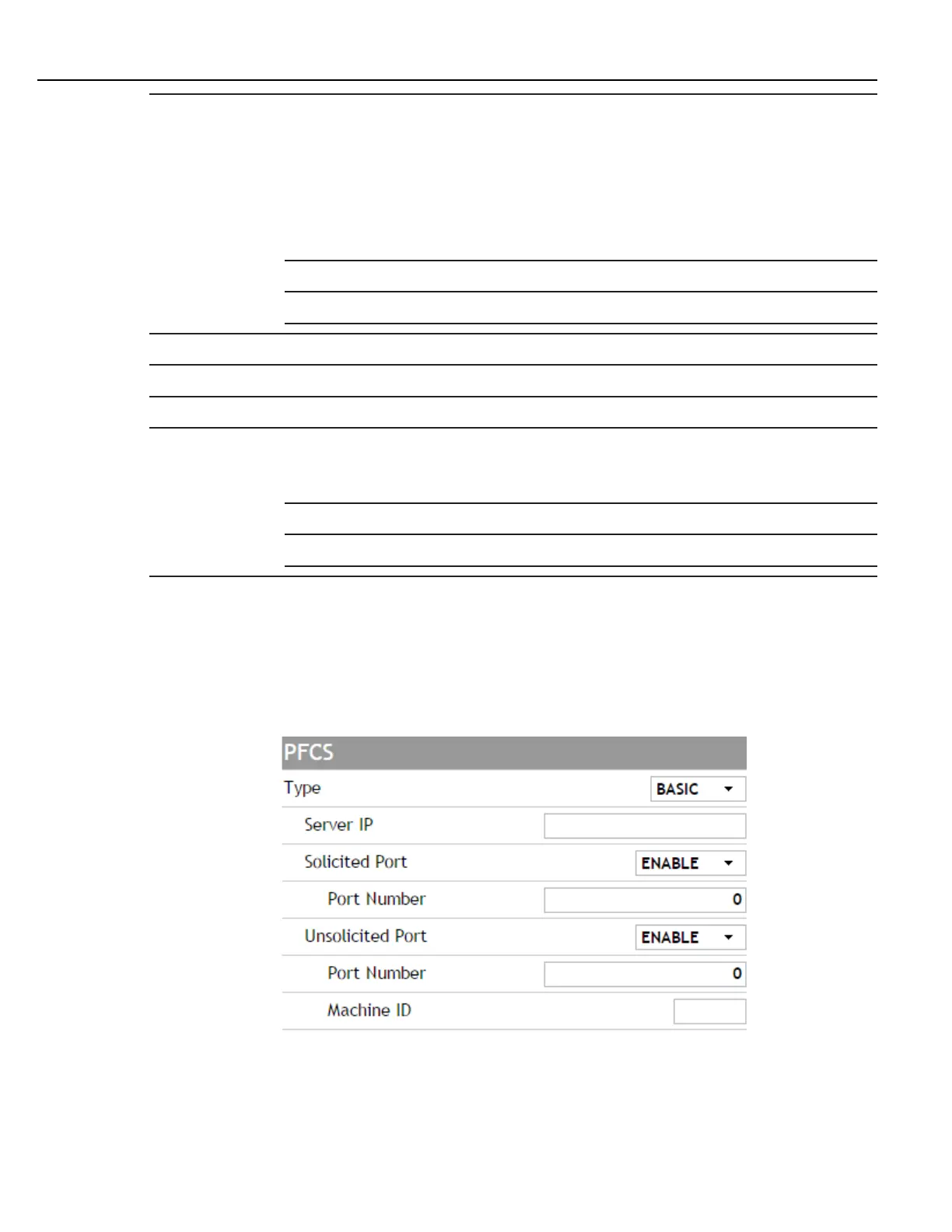

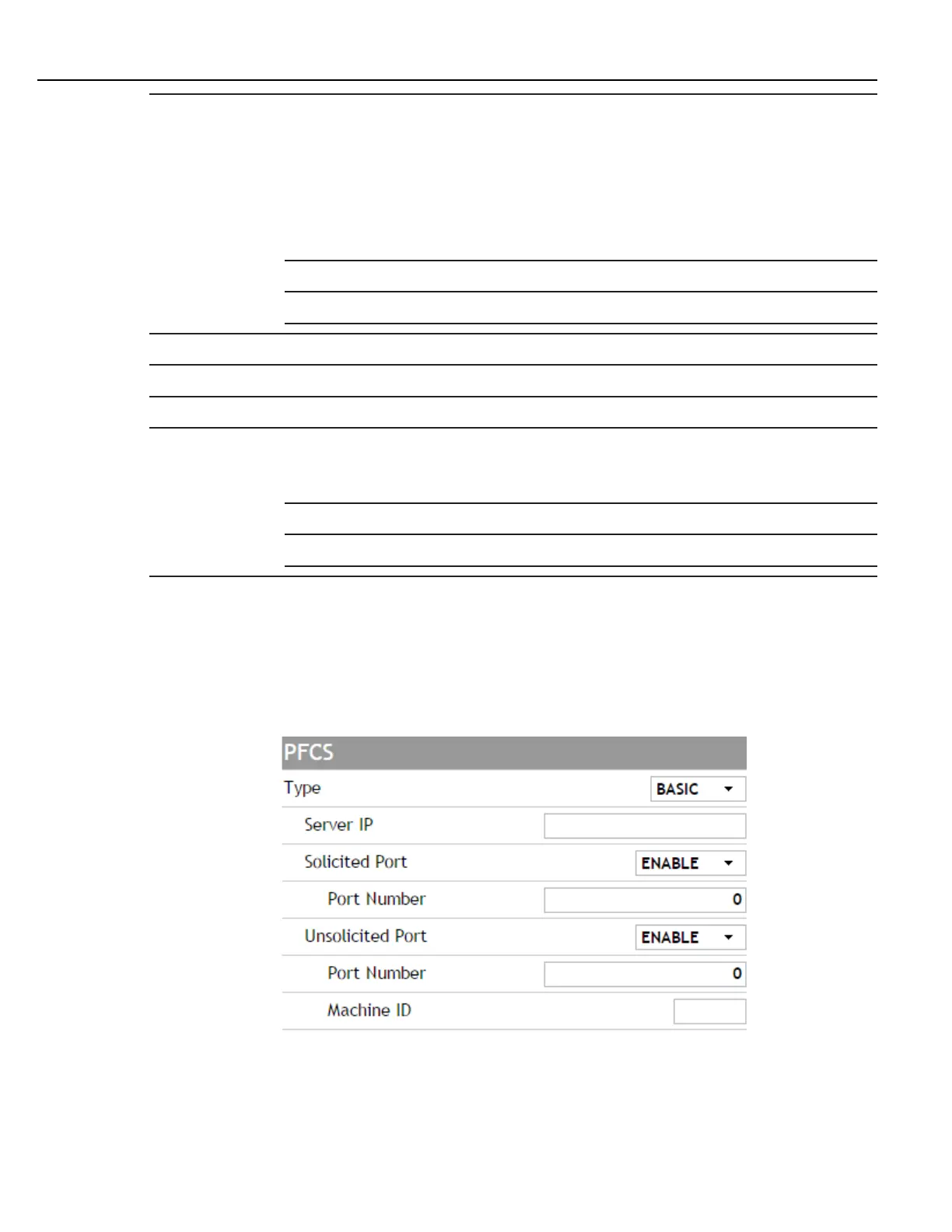

3.1.3.4 PFCS Tab

The plant’s System group must provide these values to allow the Alpha controller to communicate on the PFCS

or NPL network. If using the NPL network there is a setup per spindle, even in a multiple. Be sure to select each

spindle that needs to report to the NPL and setup these parameters.

Loading...

Loading...