WORKSHOP MANUAL

MP 84/98 - MP 84/98 Hy

3. Maintenance

This chapter covers the main aspects of a servi c

ing procedure.

A specic chapter is dedicated to a quick trouble

shooting guide on the most frequent questions

and the chapter references providing information

on the interventions required to resolve the same.

4. Adjustments and tuning

his chapter deals with the adjustments to be ma de

to remedy the more frequent performance fai lures

and are usually resolved by quick checks and tun

ings.

5. Removal of external parts and main assem-

blies

For doing more dicult jobs, greater accessibility

may be required. This can be done by taking the

unit concerned o and working at the bench, or by

removing the cover or other external parts.

Whether or not this will be useful is at the discre

tion of the mechanic’s experience.

6. Repairs

This chapter deals with all the more complex work

connected with the replacement or repair of mal

functioning or worn parts.

The descriptions must follow a logical sequence

and can include operations not specically con

nected to a particular type of repair.

In this case, careful reading of the entire procedure

can help you omit all those operations not connect

ed with the case in hand without, however, over

looking anything that may be necessary.

7. Electrical system

This chapter deals with the problems and checks

con nect ed with the electrical system.

All work can be done using a tester without ha ving

to use special equipment.

The electrical diagrams can be useful to you for

B) Identication and number of the page based on

the following criteria:

– the rst eld indicates the section and chapter;

– the second eld indicates the revision index;

– the third eld indicates the chapter validity start

date, i.e. the year of manufacture of the ma-

chine;

– the fourth eld indicates the page number and

total number of pages dedicated to the subject.

C) Chapter title.

D) General information, references to other chapters

in the manual, technical information related to the

topic, and buttons with links to the machine oper-

ating units map can be found in the left column on

each initial page.

SECTIONS OF THE MANUAL

The content of the manual is divided into sections

which correspond to the various subjects and the dif-

ferent types of servicing.

1. Rules and procedures for Service Centres

This chapter covers all the main aspects of the re

lationship between the manufacturer and the ser

vice centres.

A close collaboration between the manufacturer

and the service centres is conclusive for solv

ing problems in the most eective way as well as

maintaining an image of eciency and reliability.

Compliance with these brief and simple guide

lines will facilitate this task and prevent general

mi sunderstandings and timewasting for both the

manufacturer and the service centre.

2. General regulations

This chapter covers the main aspects of a servi

c ing procedure and the general rules for guaran

teeing a successful service which protects the

en vironment and respects the safety of both the

ser viceman and the user of the apparatus.

GENERAL INFORMATIONS

The purpose of this manual is to assist Service Cen-

tres with service, disassemble and repair the versions

of the machines:

– mechanical driven (MP 84/98);

– hydrostatic driven (MP 84/98 Hy).

The manual has left out the simplest and quickest

operations that can be handled by a good mechanic,

while concentrating more on specic aspects with

tips and advice on the best servicing procedures.

Please take time to read through this manual to ac-

quire a basic understanding of the machine, which is

necessary for working rationally without making er-

rors or wasting time.

All problems related to the use of the machine are

fully covered in the User manual.

STRUCTURE OF THE MANUAL

The manual is divided into sections and chapters.

Each page of this manual states the following infor-

mation:

A) Machines or series of machines to which the con-

tents of the chapter are applicable.

CHAPTER REVISION FROM ... PAGE

i 1 2018 1 of 2

HOW TO USE THE MANUAL

WORKSHOP MANUAL

Map of functional units

MP 84/98 - MP 84/98 Hy

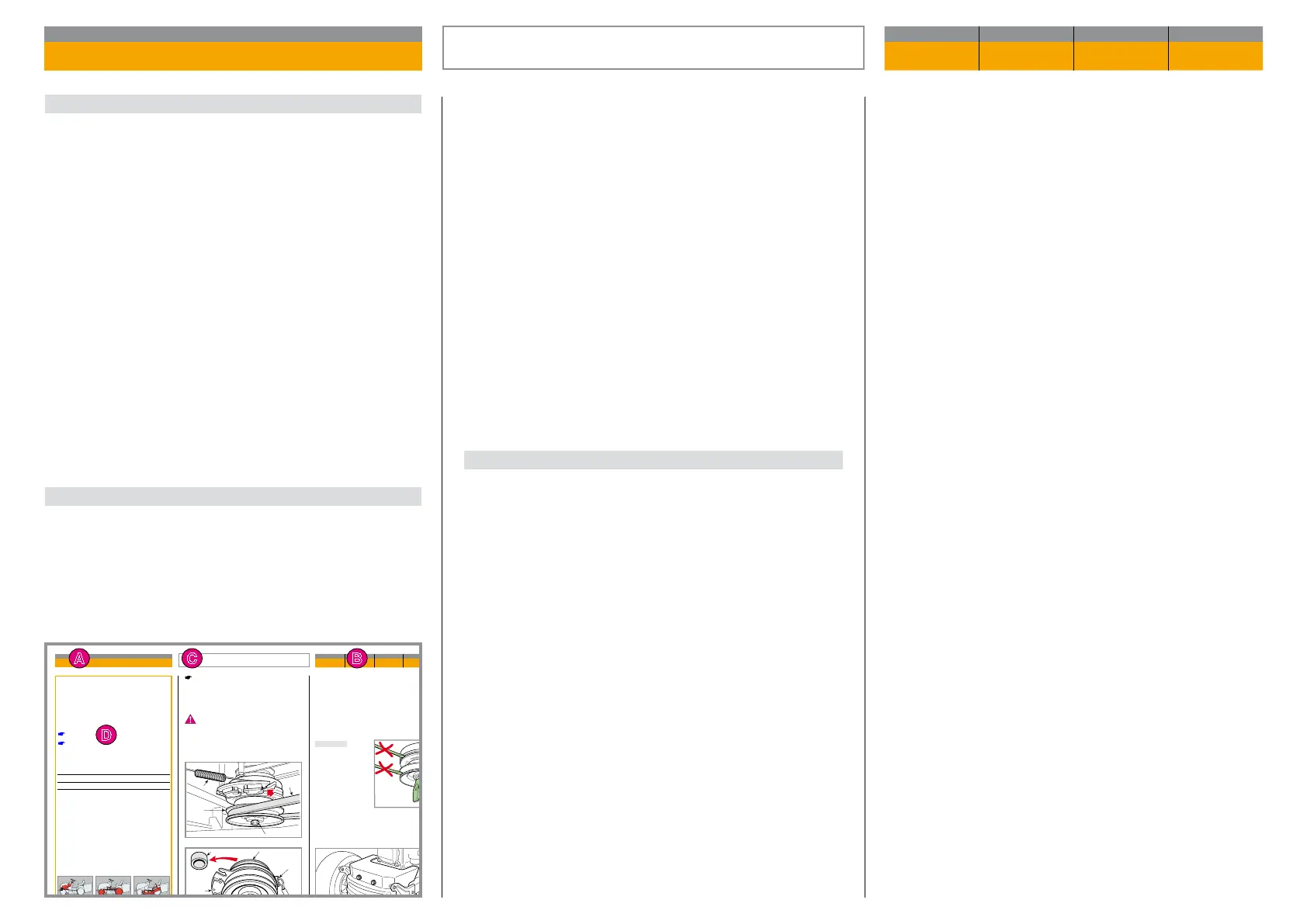

Disconnect the connectors (3) from the clutch con-

tacts (2), unhook the return spring (4) from the clutch

side and unscrew the central screw (5) with the help

of a power screwdriver.

Remove the clutch (2) from the engine shaft, together

with the transmission command pulley (6) and the

spacer (7 - if installed).

IMPORTANT To remove

the clutch (2) from the en-

gine shaft, absolutely do

not use a lever to force

the pulleys or the outer

cover. In case of diculty,

apply an unlocking spray

and gently tap on the hub

with a hammer, to facili-

tate extraction.

Remove the exhaust guard (8).

Disconnect the accelerator cable control and the

e lectrical cables.

Remove the front hood.

For greater operating convenience it is recommended

that the transmission belt is slackened o; this is done

by enga ging the parking brake.

FIRST disconnect the black earth cable from

the bat tery, and THEN the red cable, to prevent pos-

sible short circuits and dangerous situations.

Free the blade belt (1) from the clutch pulley (2).

REMOVAL OF THE ENGINE

CHAPTER REVISION FROM ...

5.5 2 2018

General informations

Since there are dierent types of drive, the stag-

es de scribed here refer to those shared or similar

in all types of engine.

Related topics

[

5.1] Removal of front hood

[

6.8] Replacement of the accelerator and ad-

justment of the carburettor

Tightening torques

5 Screw for pulley ............................. 45 ÷ 50 Nm

- Screws for engine fastening ............ 25 ÷ 30 Nm

3

2

7

6

1

2

4

5

A C B

D

Loading...

Loading...