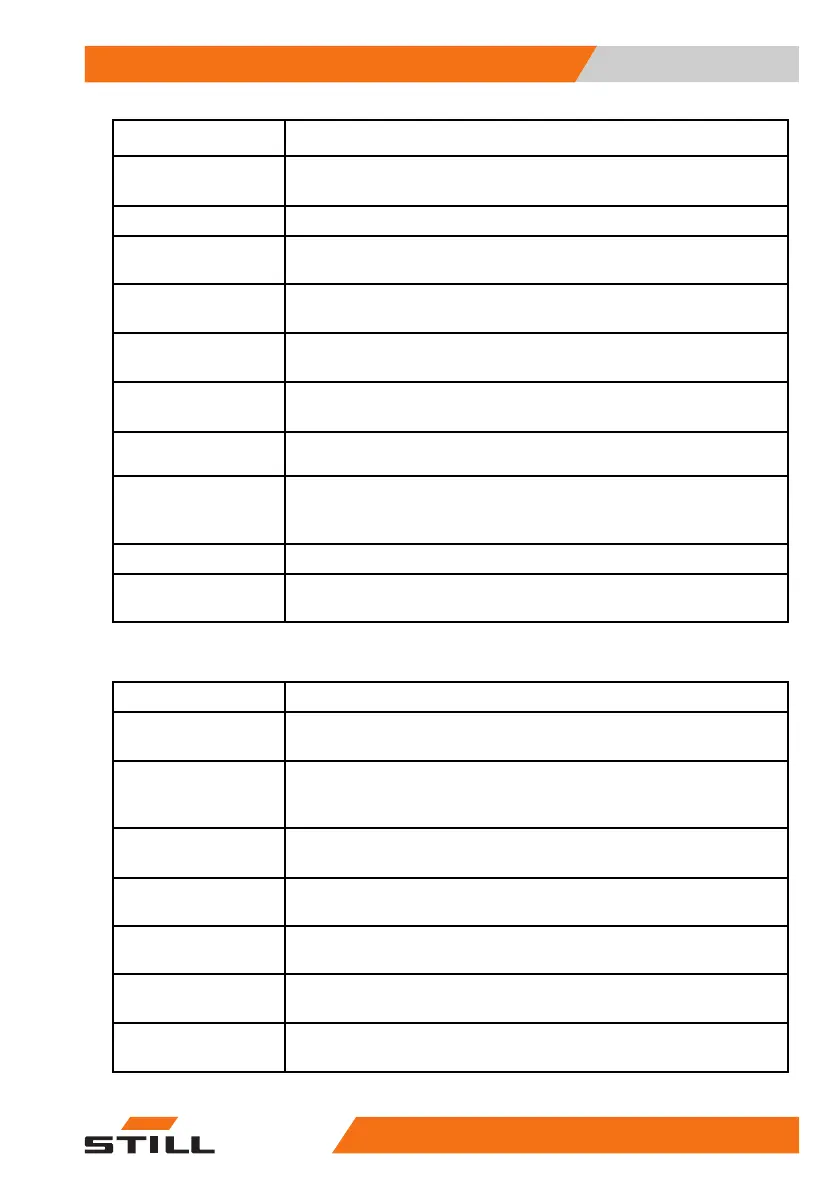

Maintenance 6

General maintenance information

Position Maintenance work

4

Check exhaust system; see ⇒ Chapter "Checking the exhaust gas

system", P. 6-227

5

Replace LPG filter; see ⇒ Chapter "Changing the LPG filter", P. 6-227

5

Overhaul gas fuel system; see ⇒ Chapter "Overhauling the LPG sys-

tem",P.6-229

-

Check lambda control system; see ⇒ Chapter "Checking the lambda

control system", P. 6-230

-

Check the heating system for leaks, see ⇒ Chapter "Checking the

heating system for leaks", P. 6-230

1

Check lift cylinders and connections for leaks, see ⇒ Chapter "Check

lift cylinders and connections for leaks.", P. 6-230

1

Service lifting system, see ⇒ Chapter "Maintain liftingsystem", P. 6-231

1

Check play between fork carriage stop and run-out stop, see ⇒ Chap-

ter "Checking the clearance between fork carriage stop and run-out

stop", P. 6-233

9

Check fork arms, see ⇒ Chapter "Checking the fork arms", P. 6-233

-

Check reversible fork arms, see ⇒ Chapter "Checking reversible fork

arms", P. 6-234

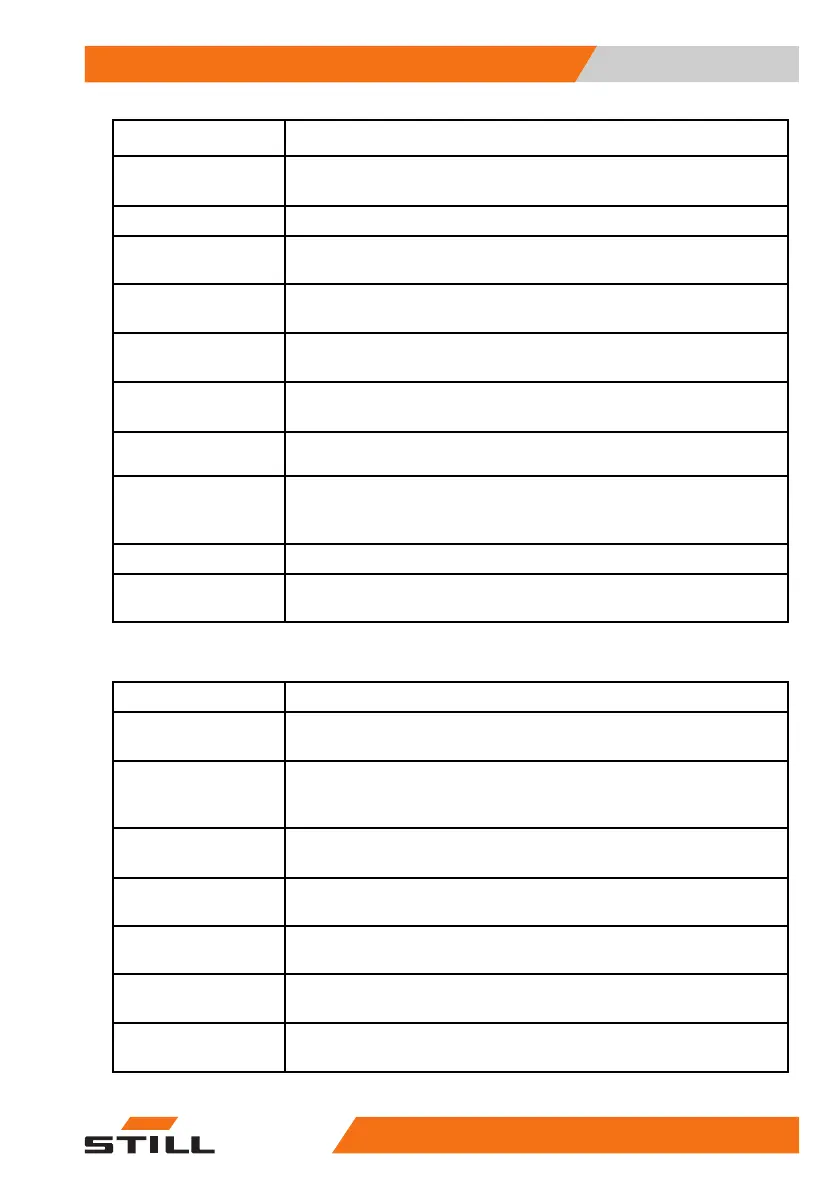

3000-hour maintenance/two-year maintenance

Position Maintenance work

-

Carry out maintenance work as necessary, see ⇒ Chapter "Mainte-

nance as required", P. 200

-

Carry out all work for 500-hour maintenance/semi-annual mainte-

nance, see ⇒ Chapter "500-hour maintenance/semi-annual mainte-

nance", P. 222

-

Carry out all work for 1000-hour maintenance/annual maintenance,

see ⇒ Chapter "1000-hour maintenance/annual maintenance", P. 223

8

Replace gear lubricant oil, see ⇒ Chapter "Changing the gear lubricant

oil", P. 6-235

-

Check wheel bearings, see ⇒ Chapter "Checking the wheel bearing

", P. 6-236

-

Check engine bearing, see ⇒ Chapter "Checking the engine mount-

ings", P. 6-236

5

Replace hoses for the gas fuel system; see⇒ Chapter "Replacing

hoses in the LPG system", P. 6-237

171673 [EN] 183

Loading...

Loading...