Seite 15 BB_ENG_991305_04_16

BUDDYBOX Operating Manual

8.8 Regreasing and oil change intervals

8.8.1 Oil change intervals

Oil level must be checked every 5,000 hours. If the oil is contaminated, burned or waxed,

change the oil immediately, and ush the gear if necessary.

The oil level can be checked by the oil level control device (refer to 8.4 and 8.5).

Under normal operating conditions oil should be changed every 10,000 hours or after 2 years

at the latest. A shorter oil change (every 3,000 or 5,000 hours) will increase the gear lifetime.

We recommend to change the oil after the rst 500 hours of operation.

The recommendations above do not apply to abnormal operating conditions, i.e., high tem-

perature, high humidity or corrosive environments. If any of these situations exist, the lubricant

may have to be changed more frequently.

8.8.2 Grease lubrication

All types with ESSO Unirex N2 are maintenance free for 20,000 hrs or 4-5 years.

All other grease lubricated types must be topped up after 500 hrs, or after 2 months in opertion

at the latest. For further regreasing intervals please refer to the tables below

Regreasing intervals

Operating conditions Regreasig interval Comments

up to 10 hours/day every 3 - 6 months

regreasing intervals must be shortened

in the case of use in difcult conditions

10 - 24 hours/day every 500 - 1000 hours

Grease change intervals

Section Grease change intervals Comments

High speed & speed

reducer section

every 2 - 3 years

regreasing intervals must be shortened in

the case of use in difcult conditions

Output every 3 - 5 years

9. Inspection and maintenance

9.1 Re-greasing of grease lubricated CYCLO Drive units

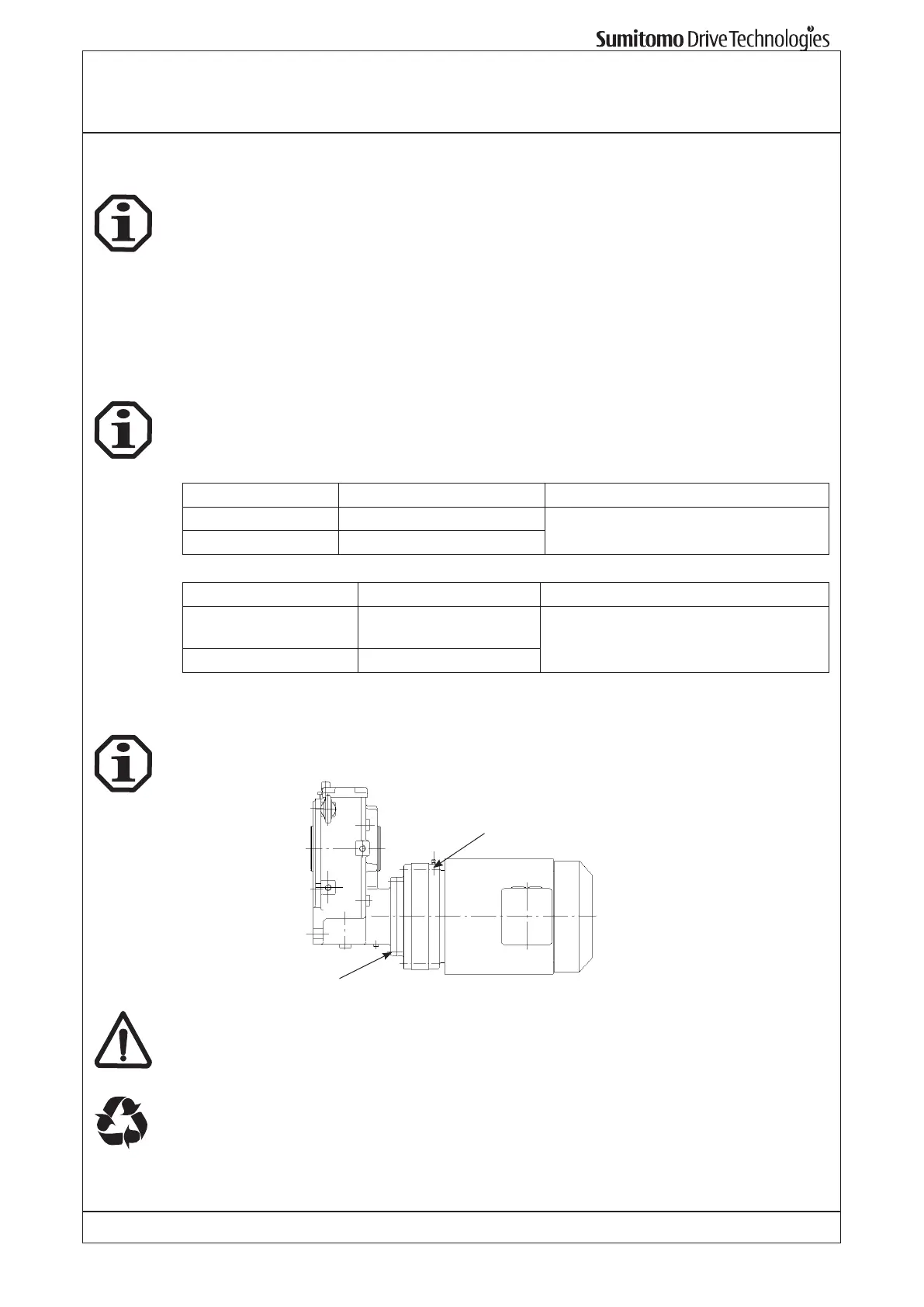

Unfasten the grease control screw and replenish with a grease gun through the grease nipple

at the ange on the input part or the motor ange

grease nipple

grease control screw

Continue re-greasing with the gear unit in operation to provide proper circulation of the grease.

For each re-greasing use about one third to half of the quantity shown by the graph in 8.2.1

and 8.2.2. If too much grease is applied, the operating heat can lead to a rise in the lubricant

temperature or grease might be forced into the motor or escape through the seals.

Remove grease residuals on the control screw and dispose of as required by environmental

regulations

Loading...

Loading...