Seite 8 BB_ENG_991305_04_16

BUDDYBOX Operating Manual

6. Electrical installation

6.1 Safety advice

Installation, start up and servicing should only be done by qualied personnel.

Before commencing upon the servicing of the motor or the gearmotor, particularly

before opening covers to active parts, the main electrical supply must be discounted.

Please follow the ve safety rules according to DIN VDE 0105.

The motors comply with the low voltage directives 2014/35/EG.

6.2 Range of use

The motors are totally enclosed fan cooled. Standard protection is IP55, and with brake IP 44.

Ambient temperature: -10° . . . +40°C

Ground level: < 1000 m

Winding is insulation class F (150°C). It is normal for the reducer to operate at a housing

temperature of up to 100°C. Therefore, any contact with them must be prevented. Temperature

sensitive parts must never be fastened to or be in contact with the motor.

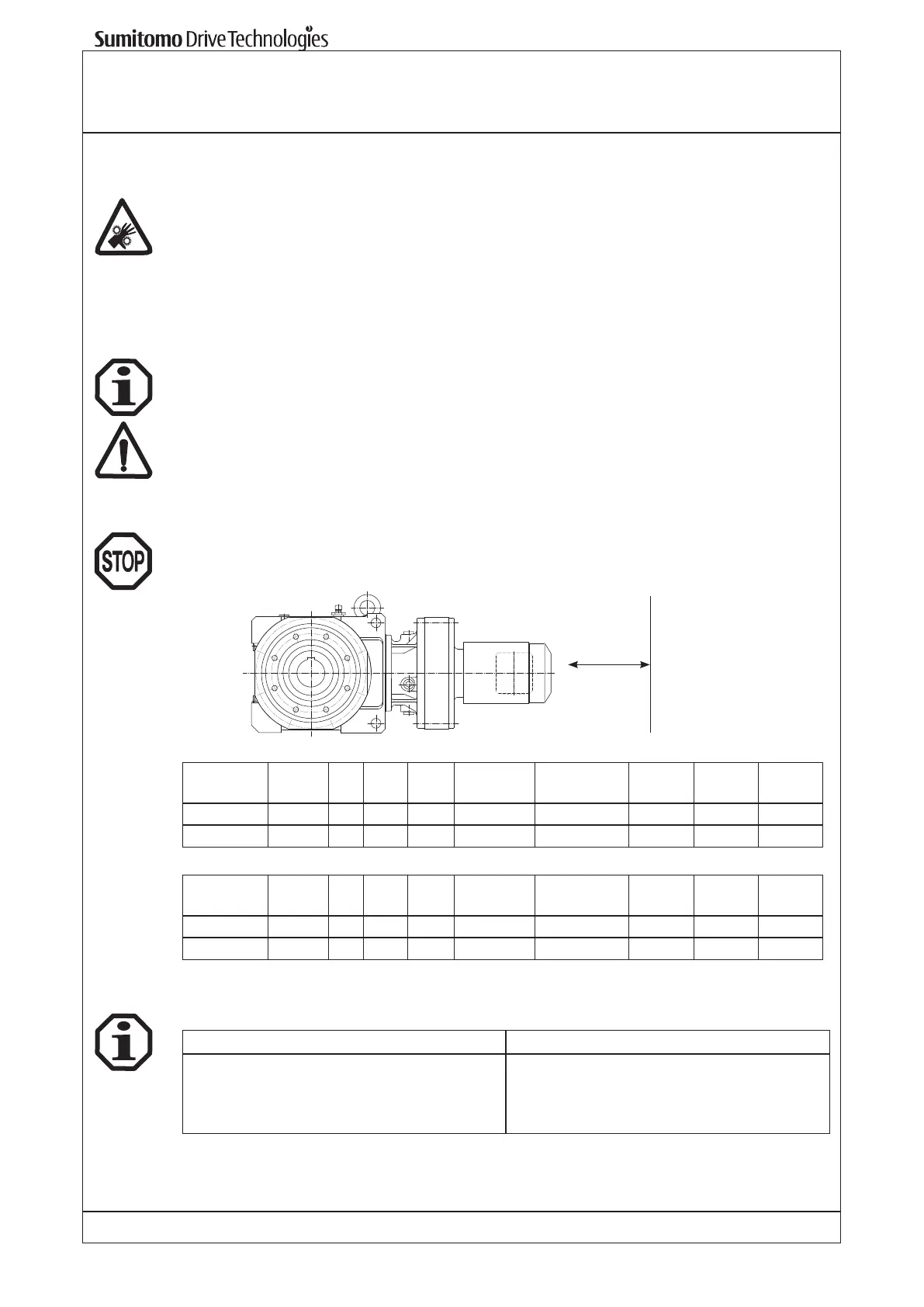

6.3 Installation

Ventilation openings must be kept clear.

For correct cooling the distance FB is the minimum required between the fan cover and the wall.

FA is the minimum clearance required for disassembling the fan cover.

FA or FB

Standard motor

Motor-

Size:

63 - 71 80 90 100 112-132S 132M-160M 160L 180M 180L

FB (mm): 20 20 20 20 20 25 30 30 30

FA (mm): 48 49 52 56 60 75 130 155 170

Brake motor

Motor-

Size:

63 - 71 80 90 100 112-132S 132M-160M 160L 180M 180L

FB (mm): 20 20 20 20 25 25 30 30 30

FA (mm): 61 93 115 121 132 170 220 367 370

6.4 Cable inlet threads sizes

The following thread sizes are suitable for the standard motors

Frame size Conduit thread

63 - 71

80 - 132S

132M - 160

180

1x M16 x 1,5 / 1x M25 x 1,5

2x M25 x 1,5

2x M32 x 1,5

2x M40 x 1,5

Cable glands suitable for the motor protection level must be used.

Any unused cable entries must be closed, to the correct motor protection level.

Loading...

Loading...