INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

SUMMIT PUMP MODEL CCFM GENERAL PURPOSE 13

NOTICE

Do not operate pump dry. Dry operation can

cause premature damage to pump

internals.

7.2.1 Start Up

1. Crack open the discharge valve to allow flow yet still give the pump resistance.

2. Before operating the pump, it must be filled with liquid. This can be done by removing

discharge piping and fill with the pumped liquid or water. (Only use water if it will not

contaminate the pumping liquid.). If in a flooded suction, opening the suction valve will fill

the pump piping.

3. Ensure the motor rotation coincides with desired pump rotation. Refer to Section 6.5 on page

10 for specific shaft rotation direction.

4. Ensure all plugs, gauges, seals are installed and any seal clips are removed.

5. Start the pump.

7.2.2

Shut Down

1. If possible, flush the pump with clean water. (Only use water if it will not contaminate the

pumping liquid.)

2. Close the discharge valve to minimum flow of the pump.

3. Shut down the pump.

4. Close both the discharge and suction valves.

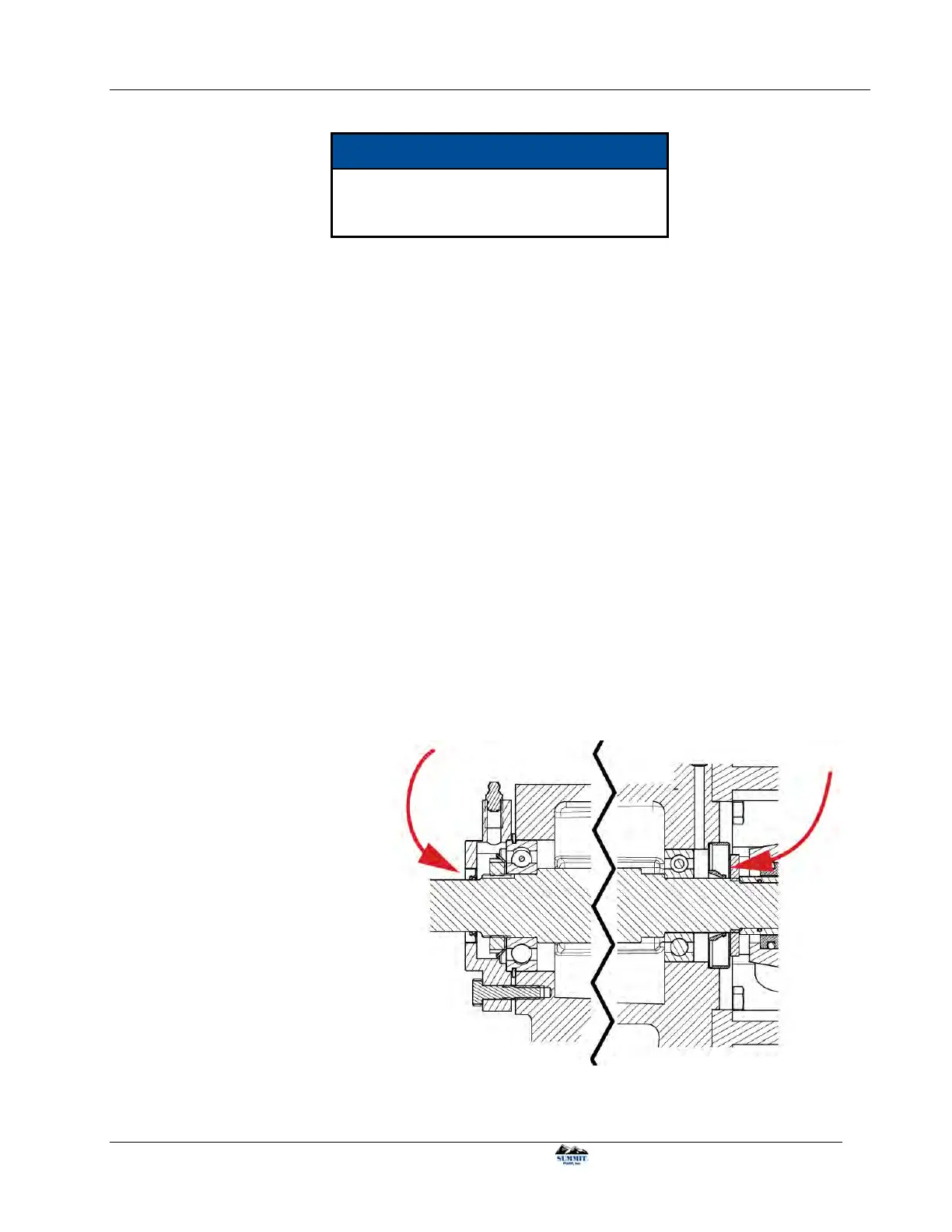

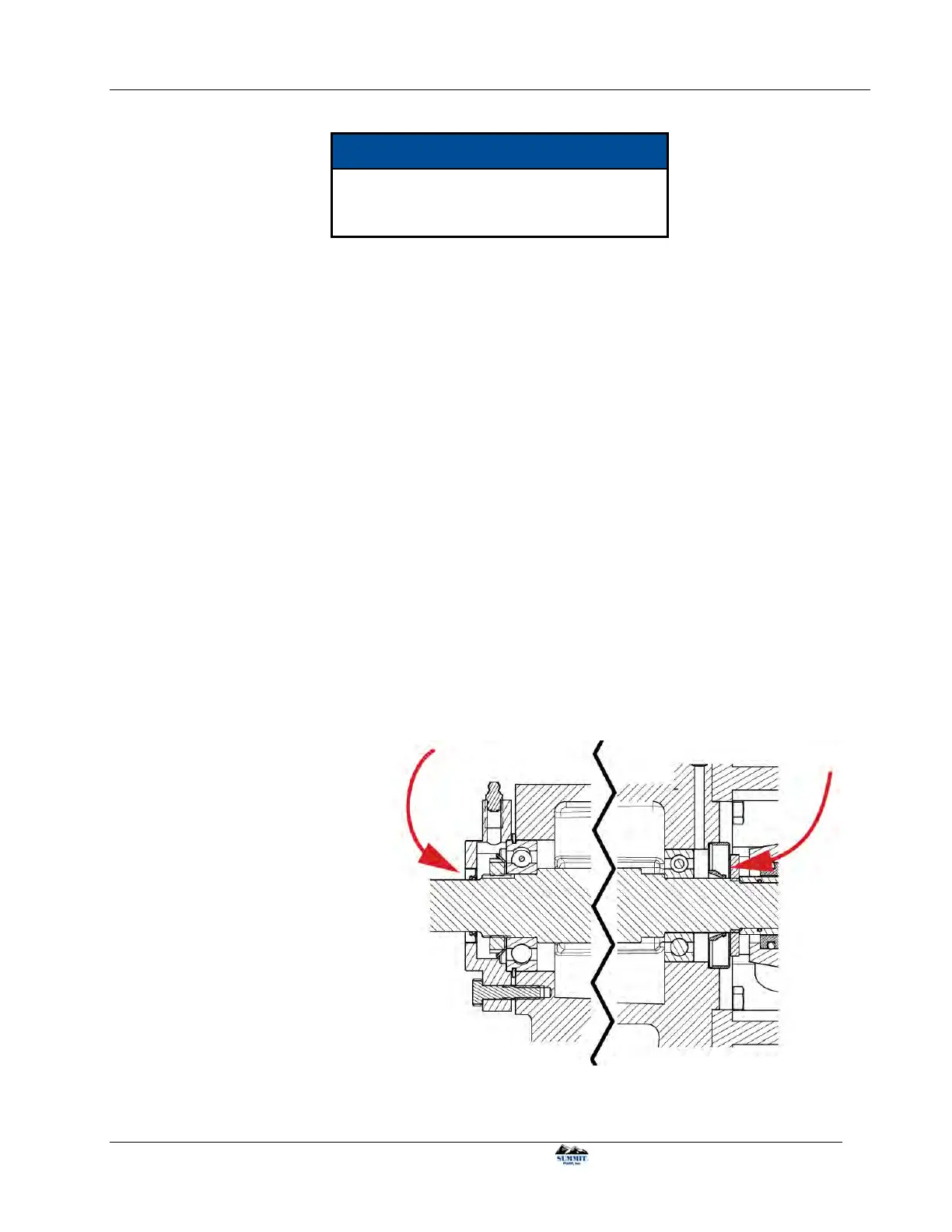

7.3 Lubrication

Ensure lip seals (49, 51), bearings

(16, 18) and motor bearings (see

motor manufacturer’s

recommendations) are adequately

lubricated for the service duty. Make

sure lip seals are installed in the

correct orientation; the lips should

face away from the frame (19). The

arrows in Figure 7-1 are pointed

towards the springs which should be

visible when viewing the pump. This

allows for leakage of excess grease

since there is no overflow opening.

Bearings are greased at the factory.

Figure 7-1: Lip seal (49, 51) orientation

Loading...

Loading...