INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

SUMMIT PUMP MODEL CCFM GENERAL PURPOSE 27

12.1 POWER END

Collect the pump parts together and build on a clean work bench or station. It is critical to keep

mechanical seal faces and bearing free from debris. The entire pump should be assembled before

installing on the base plate and making shaft alignments.

1. Install the bearings (16, 18) onto the shaft (06). This can be done using a bearing heater and

sliding the bearings (16, 18) into their positions. Another option would be using an arbor that

fits around the shaft (06) and onto the inner raceway of the bearing (16, 18) and pressing it

onto the shaft (06) using a hydraulic press. Never pound bearings (16, 18) using an impact

force to install.

Be sure that inner raceways are set square to the resting shoulder of the shaft (06).

NOTICE

NEVER use impact force to install bearings

2. Clamp the shaft (06) with a vice between the bearings (16, 18) as this is a non-critical surface

of the shaft. Install the bearing lock washer (22A) and bearing locknut (22). Be sure that the

bearing lock washer (22A) inner diameter tab is within the groove of the shaft (06).

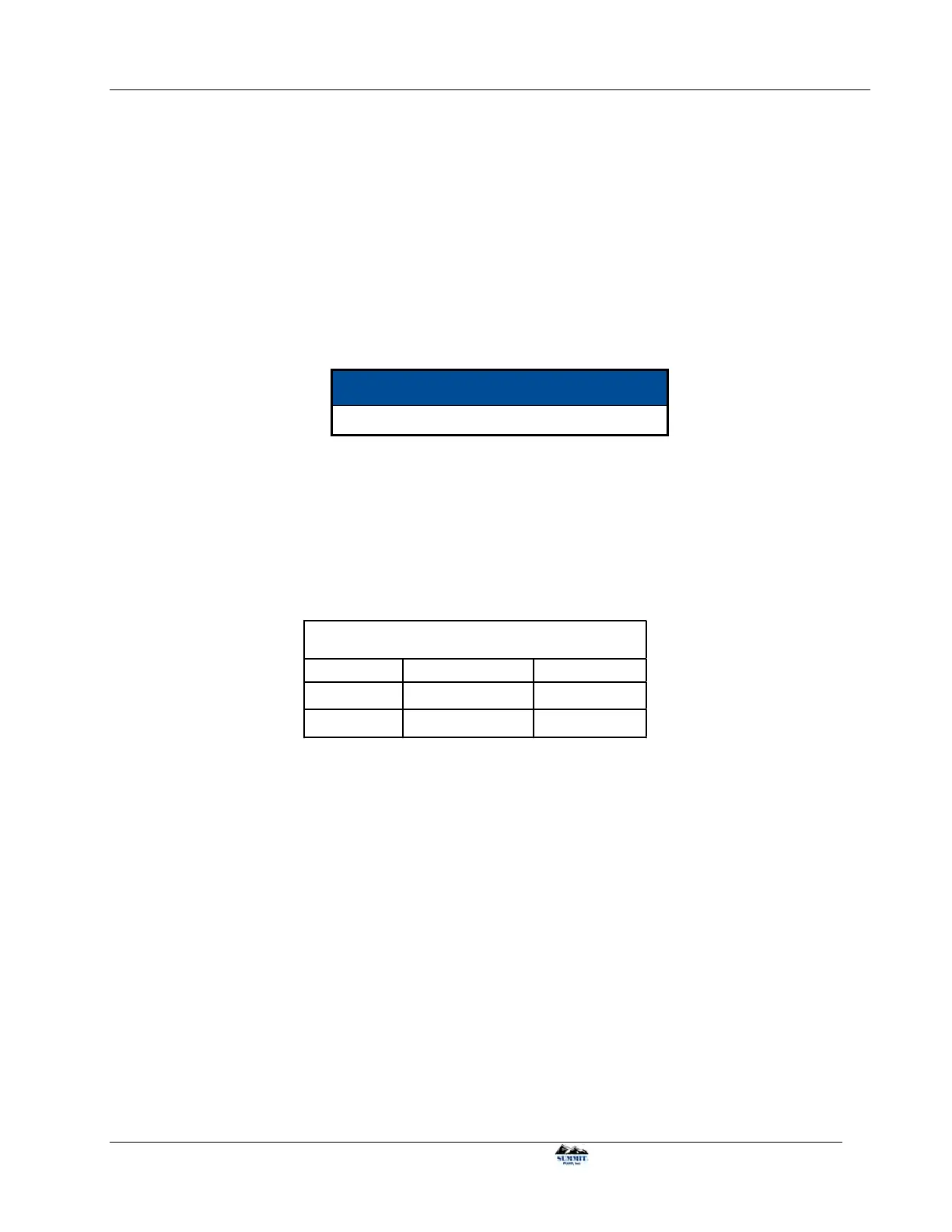

3. Hand tighten the locknut (22) to the lock washer (22A). Then torque the locknut (22) to the

values in

Table 12-2.

4. Install a new lip seal (49) into the bearing cover (37). The lip of the lip seal (49) should face

towards the couple end of the shaft (06) (i.e. the spring should be visible when bearing cover

(37) is installed). See Figure 7-1 on page 13.for clarification. Using the same grease as the

bearings, apply a light layer of grease to the lip of the seal.

5. Install a new lip seal (51) into the frame (19). The lip of the lip seal (51) should face the

impeller end of the shaft (06) (i.e. the spring should be visible). See Figure 7-1 on page 13 for

clarification. Using the same grease as the bearings, apply a light layer of grease to the lip of

the seal.

6. Hand pack each bearing (16, 18) filling the cavities between the balls. See Section 7.3 on page

13 for lubrication specifications. This hand packing will be sufficient until lubrication

frequency is reached. Extreme cleanliness is critical at this point of assembly.

7. Take the shaft (06) and installed bearings (16, 18), carefully and squarely slide this assembly

into the bearing bores of the frame (19), take care not to damage the lip seal (51). When both

bearings (16, 18) are in their respected bearing bores, lightly tap the coupling end of the shaft

Frame Size Locknut Size Torque (lbft)

Frame 1 N07 32

Frame 2 N08 40

Bearing Locknut (22) Torques

Table 12-2: Bearing locknut (22) torques.

Loading...

Loading...