INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

SUMMIT PUMP MODEL CCFM GENERAL PURPOSE 23

The order the following adaptor kit parts get removed may change depending on the frame size,

materials of construction of the pump and how long the pump has been sitting dry. The main concern

is keeping the seal faces clean and undamaged when removing, take caution when this happens.

1. Remove the mechanical seal spring (80B). This will not be possible with the FM1 and CC1

Stainless version, the impeller sleeve O-Ring (131) can be removed in this case.

2. Remove the adaptor to frame bolts (71A). As smoothly and as close to parallel to the shaft as

possible, remove the adaptor (71) by sliding it along the shaft. This should pull the sleeve

(14), shaft sleeve O-Ring (130) and mechanical seal components (65, 80) off with the adaptor.

3. When adaptor (71) is free of the shaft (06), immediately tip the adaptor (71) back towards the

shaft (06) to keep the sleeve (14) and rotating member (80) from falling out, protecting the

seal faces.

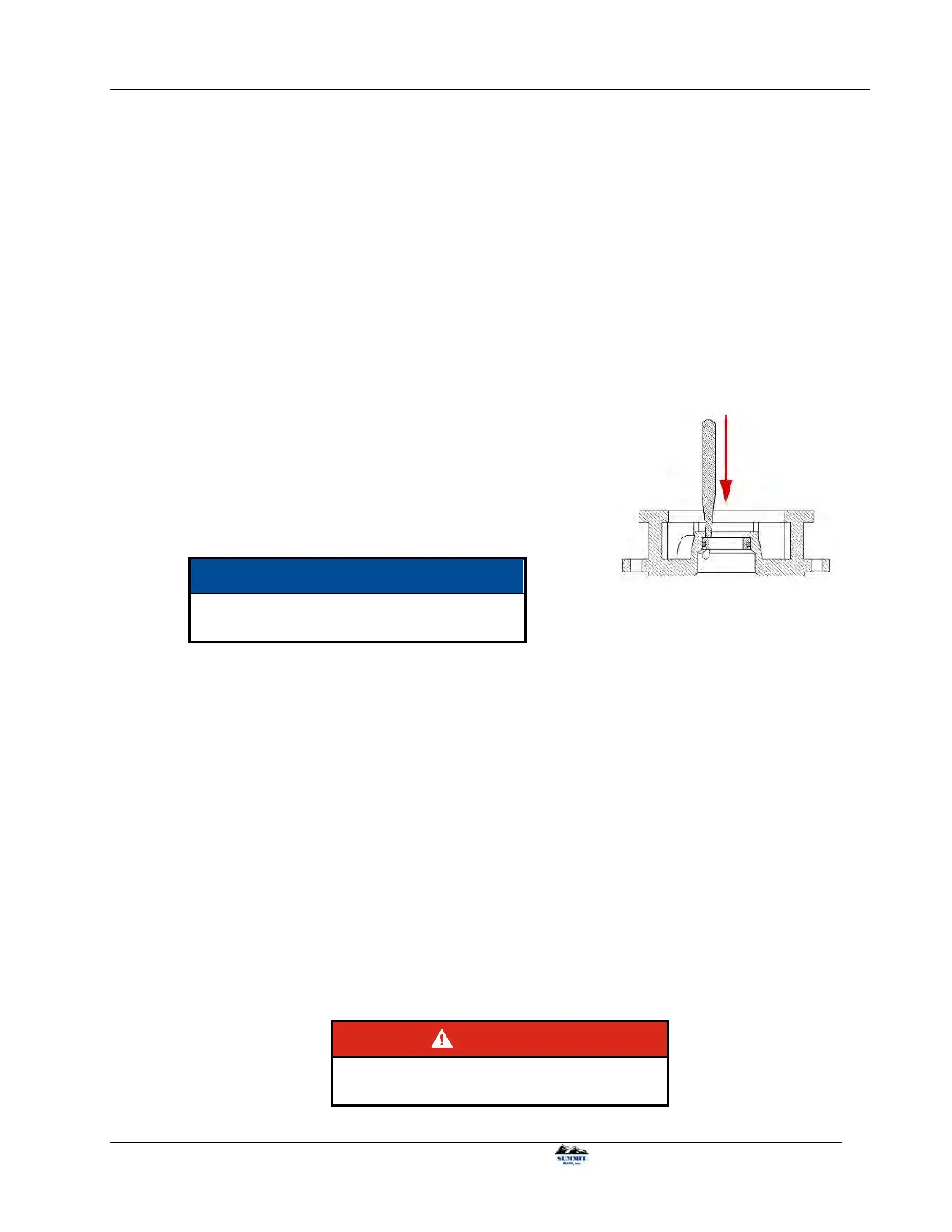

4. Within the adaptor (71), separate all parts that have been

removed from the pump. The stationary element (65) will

still be in the adaptor (71). To remove, use a blunt or flat

punch and push out the stationary element (65) by hand, do

not use a hammer as it will shatter the stationary element

(65).

Push stationary element out by hand. DO

NOT use hammer

5. If the sleeve (14) is still on the shaft, grab the sleeve (14) and pull towards the end of the shaft

(06) to remove. Use a small flat screwdriver to flip up the shaft sleeve O-ring (130) and

remove from the sleeve (14).

6. Slide the deflector (40) off the shaft (06).

11.3 POWER END

This section will only cover the FM (Frame Mounted) equipment type pumps as the CC (Close

Coupled) uses a motor. Both stainless and cast iron/bronze materials with a FM1 or FM2 use the

same disassembly procedure.

1. The pump should already be disconnected from the driver mechanically and electrically, if not

do so. Remove the power end of the pump from the baseplate and move to a clean workbench.

Lock out driver power before beginning to

work on pump.

Figure 11-1: Removal of

stationary element (65)

Loading...

Loading...