2. Scale

1. Paint

6A1-74 ENGINE MECHANICAL (G13B, 1-CAM 16-VALVES ENGINE)

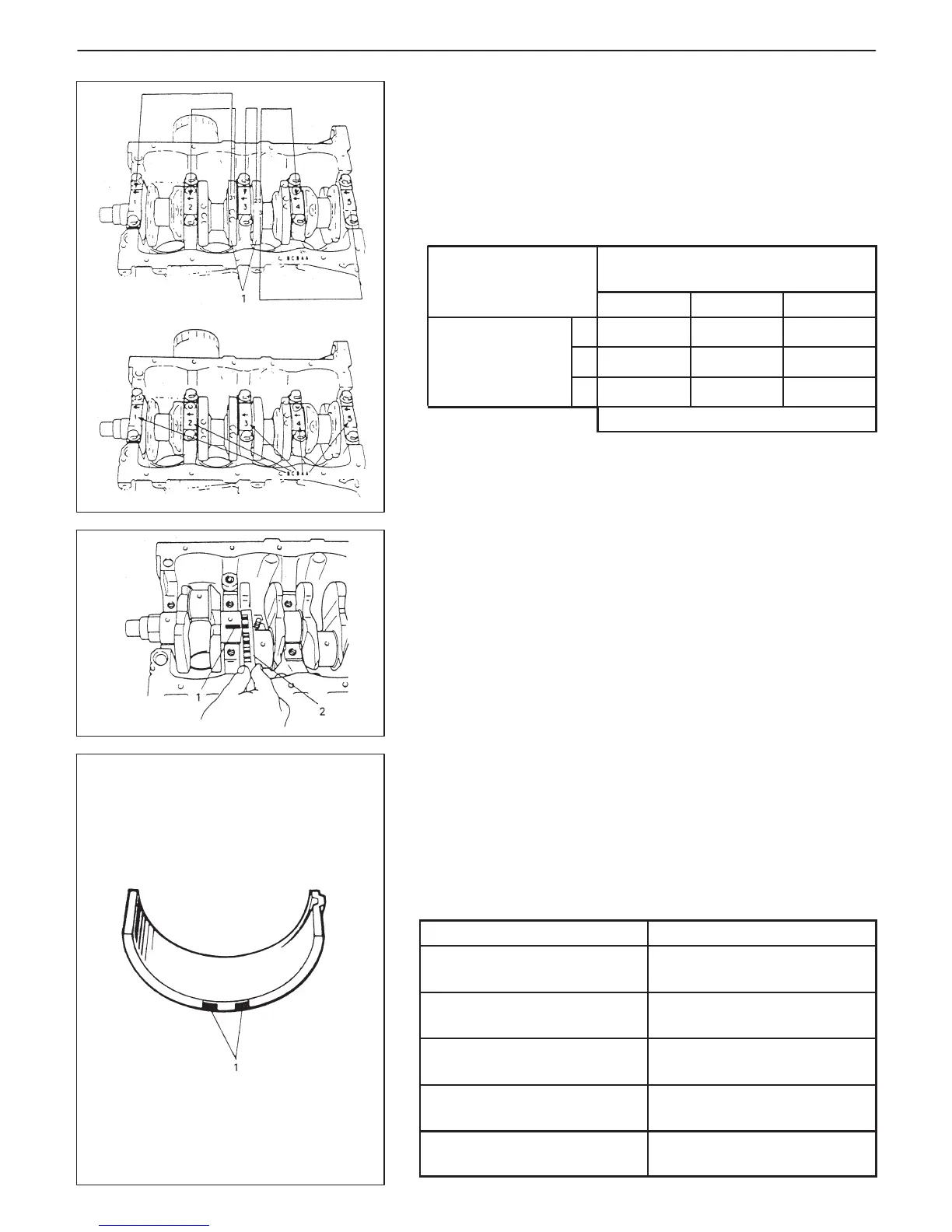

4) From numerals stamped on crank webs (1) of No.2 and No.3 cyl-

inders and the alphabets stamped on mating surface of cylinder

block, determine new standard bearing to be installed to journal,

by referring to table given below.

For example, if numeral stamped on crank web is “1” and alpha-

bet stamped on mating surface is “B”, install a new standard

bearing painted in “Black” to its journal.

Numeral stamped on crank web

(Journal diameter)

1 2 3

Alphabet stamped

dia.)

C

Colorless Yellow Blue

New standard bearing to be installed.

5) Using gaging plastic (1), check bearing clearance with newly se-

lected standard bearing.

If clearance still exceeds its limit, use next thicker bearing and

recheck clearance.

6) When replacing crankshaft or cylinder block due to any reason,

select new standard bearings to be installed by referring to nu-

merals stamped on new crankshaft or alphabets stamped on

mating surface of new cylinder block.

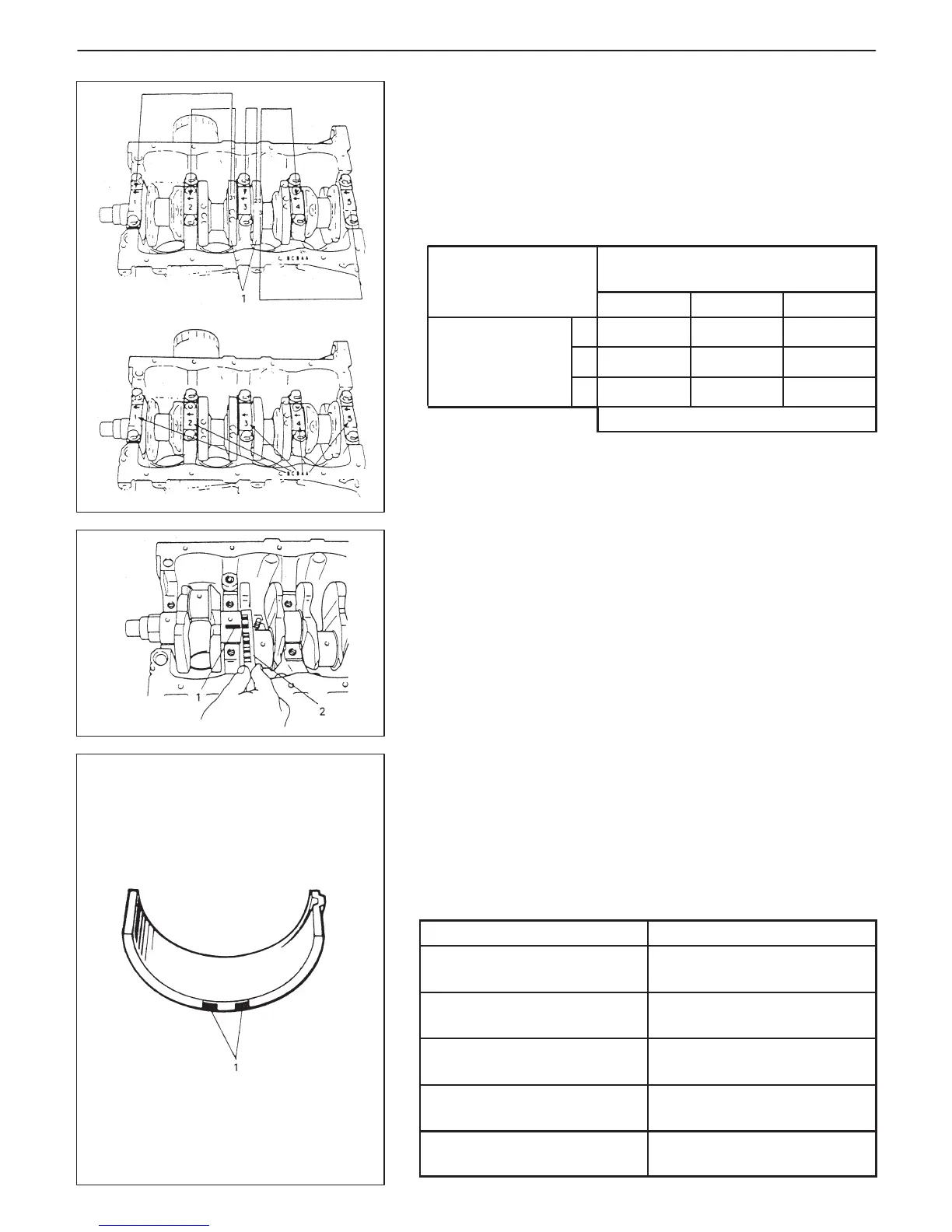

UNDERSIZE BEARING (0.25 mm):

D 0.25 mm undersize bearing is available, in five kinds varying in

thickness.

To distinguish them, each bearing is painted in the following col-

ors at such position as indicated in figure.

Each color represents the following thicknesses at the center of

bearing.

Color painted

Bearing thickness

Green & Red

2.121 – 2.125 mm

(0.0835 – 0.0836 in.)

Black & Red

2.124 – 2.128 mm

(0.0836 – 0.0837 in.)

Red only

2.127 – 2.131 mm

(0.0837 – 0.0838 in.)

Yellow & Red

2.130 – 2.134 mm

(0.0838 – 0.0839 in.)

Blue & Red

2.133 – 2.137 mm

(0.0839 – 0.0840 in.)

Loading...

Loading...