4. Press the green ‘TEST’ button. This will allow the gas in the syringe to be pulled out by the

pump inside the instrument. DO NOT push the gas into the instrument. The syringe must not

be touched while the test is running.

5.6.2 Testing Rigid Packages

If the test package is made of a material that cannot be penetrated by a needle, then a rigid package

and can piercing station can be used. Systech Illinois has several options available for accessing the

headspace within rigid packages and cans. Please contact Systech Illinois for more information.

5.7 Filters

A filter should always be used when using the analyzer. This is to prevent dust and moisture from

entering the internal gas detection system. Failure to observe this procedure may result in damage to

the instrument. The standard filters supplied with the flexible package kit will be suitable for most

applications.

The life of a filter is dependent upon many variables such as the volume of testing, test conditions, the

product being sampled, user technique, etc. The filter should be changed regularly and not allowed to

become saturated or blocked with debris. If the filter becomes blocked (or there is any restriction in the

flow to the sample system), a failure message will appear in the instrument display “Prbl” (Sample

Probe blocked).

Failure to regularly change the filter will result in dust/liquid becoming visible in the micro bore tube

leading to the analyzer. In this case, the Sample Probe (Wand), filter, and needle must be replaced.

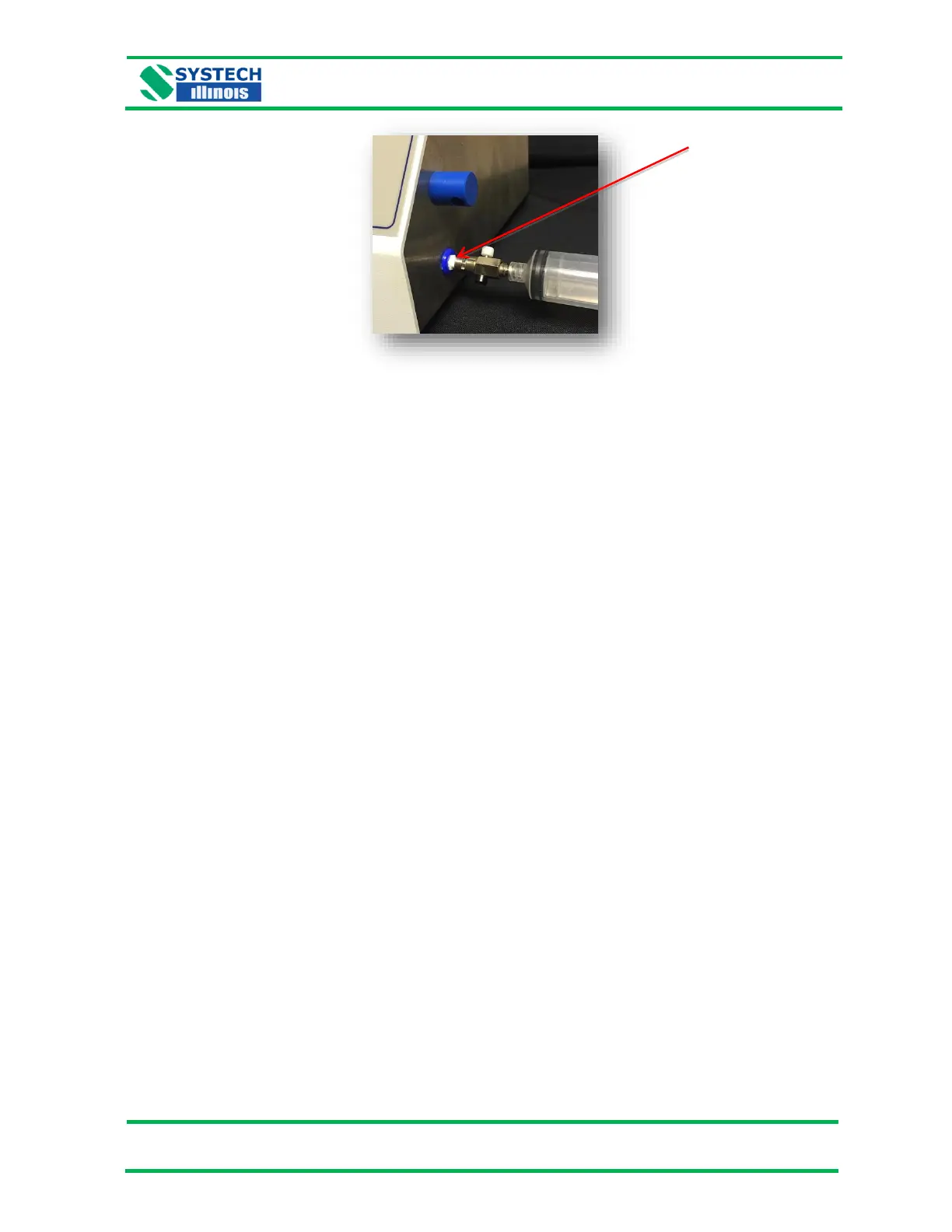

Below is the standard filter provided with the analyzer which works well for most applications:

• Part No: PFL-305143 or 100 702 Moisture / particulate filter – 0.2 micron 30mm

diameter

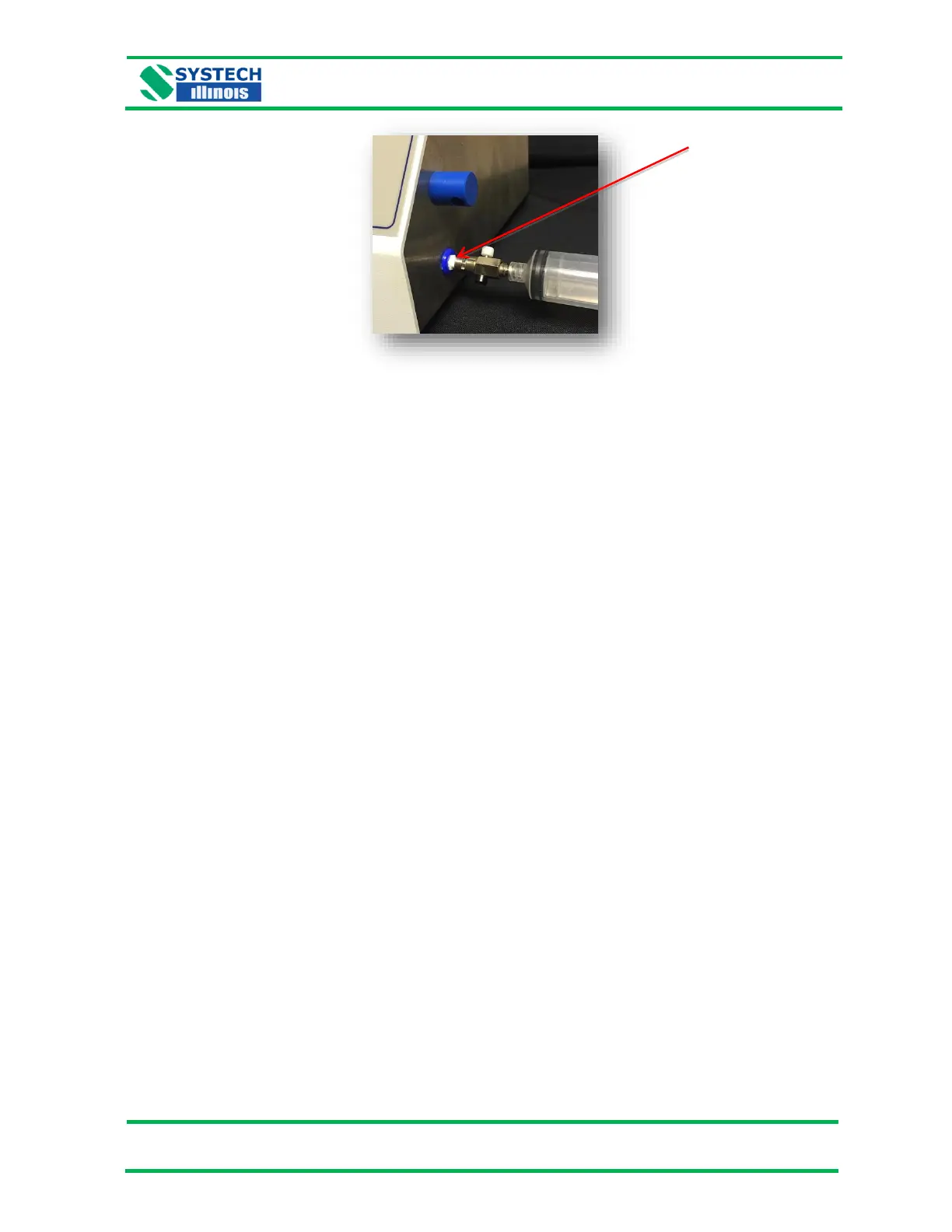

The filter below is a better choice for when headspace volume is limited:

• Part No: 101 230 Moisture / particulate filter – 0.2 micron 13mm diameter

Loading...

Loading...